Extraction method of wheat peptone

An extraction method, the technology of wheat peptone, is applied in the field of plant-derived microbial culture medium material extraction, which can solve the problems of difficult separation process, heat-sensitive substances being damaged, and the degree of protein hydrolysis cannot be achieved, so as to achieve thorough hydrolysis, deepen the depth of hydrolysis, The effect of ensuring purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

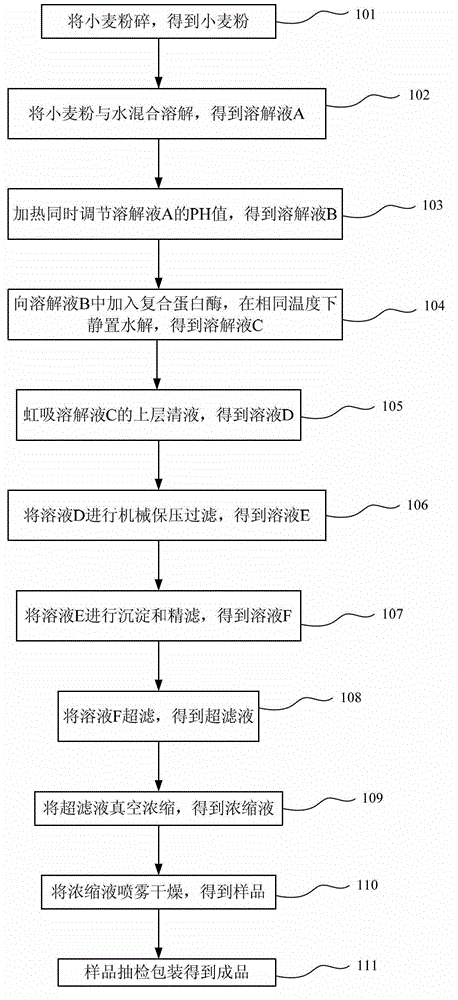

[0029] Embodiment 1: below in conjunction with attached figure 1 The present invention is described in further detail.

[0030] A method for extracting wheat peptone, comprising the following steps:

[0031] Step 101: pulverizing wheat to obtain wheat flour;

[0032] Step 102: Mix and dissolve wheat flour and water to obtain solution A;

[0033] Step 103: heating while adjusting the pH value of the solution A to obtain the solution B;

[0034] Step 104: At the same time, add complex protease to the lysate B, and hydrolyze at a constant temperature to obtain a lysate C;

[0035] Step 105: Siphon the supernatant of solution C to obtain solution D;

[0036] Step 106: Perform mechanical pressure-holding filtration on solution D to obtain solution E;

[0037] Step 107: Perform amylose precipitation and refined filtration of precipitated starch on solution E to obtain solution F;

[0038] Step 108: ultrafiltering the solution F to obtain an ultrafiltrate;

[0039] Step 109: c...

Embodiment 2

[0043] Embodiment 2: the present invention provides a kind of wheat peptone extraction method, comprises the following steps:

[0044] Step 101: pulverizing wheat to obtain wheat flour;

[0045] Step 102: Mix and dissolve wheat flour and water to obtain solution A;

[0046] Step 103: heating while adjusting the pH value of the solution A to obtain the solution B;

[0047] Step 104: At the same time, add complex protease to the lysate B, and hydrolyze at the same temperature to obtain the lysate C;

[0048] Step 105: Siphon the supernatant of solution C to obtain solution D;

[0049] Step 106: Perform mechanical pressure-holding filtration on solution D to obtain solution E;

[0050] Step 107: Perform amylose precipitation and fine filtration of precipitated starch on solution E to obtain solution F;

[0051] Step 108: ultrafiltering the solution F to obtain an ultrafiltrate;

[0052] Step 109: concentrating the ultrafiltrate in vacuum to obtain a concentrate;

[0053] St...

Embodiment 3

[0065] Embodiment 3: Embodiment 3 is identical with embodiment 2, and difference is:

[0066] The wheat powder and water are dissolved according to 1:12;

[0067] The vacuum degree in the vacuum concentration is -0.08MP;

[0068] The amylose precipitation and fine filtration of the precipitated starch are carried out at 40°C;

[0069] The pH value is 9.0;

[0070] The constant temperature of the hydrolysis is 45°C;

[0071] The time of standing hydrolysis is 6 hours;

[0072] The weight of the compound protease added when hydrolyzing wheat flour is 1% of wheat flour weight.

[0073] The invention effectively ensures the purity of the wheat peptone by adopting amylose precipitation at 40 DEG C and fine filtration removal of the precipitated starch; further ultrafiltration realizes the separation, concentration and purification of large and small molecules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com