A method for high-yield fermentation of recombinant proline aminopeptidase and preparation of debittered rice peptide

A proline aminopeptidase, high-yield technology, applied in the fields of food additives, enzyme preparations, fermentation technology, and can solve problems such as impact fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

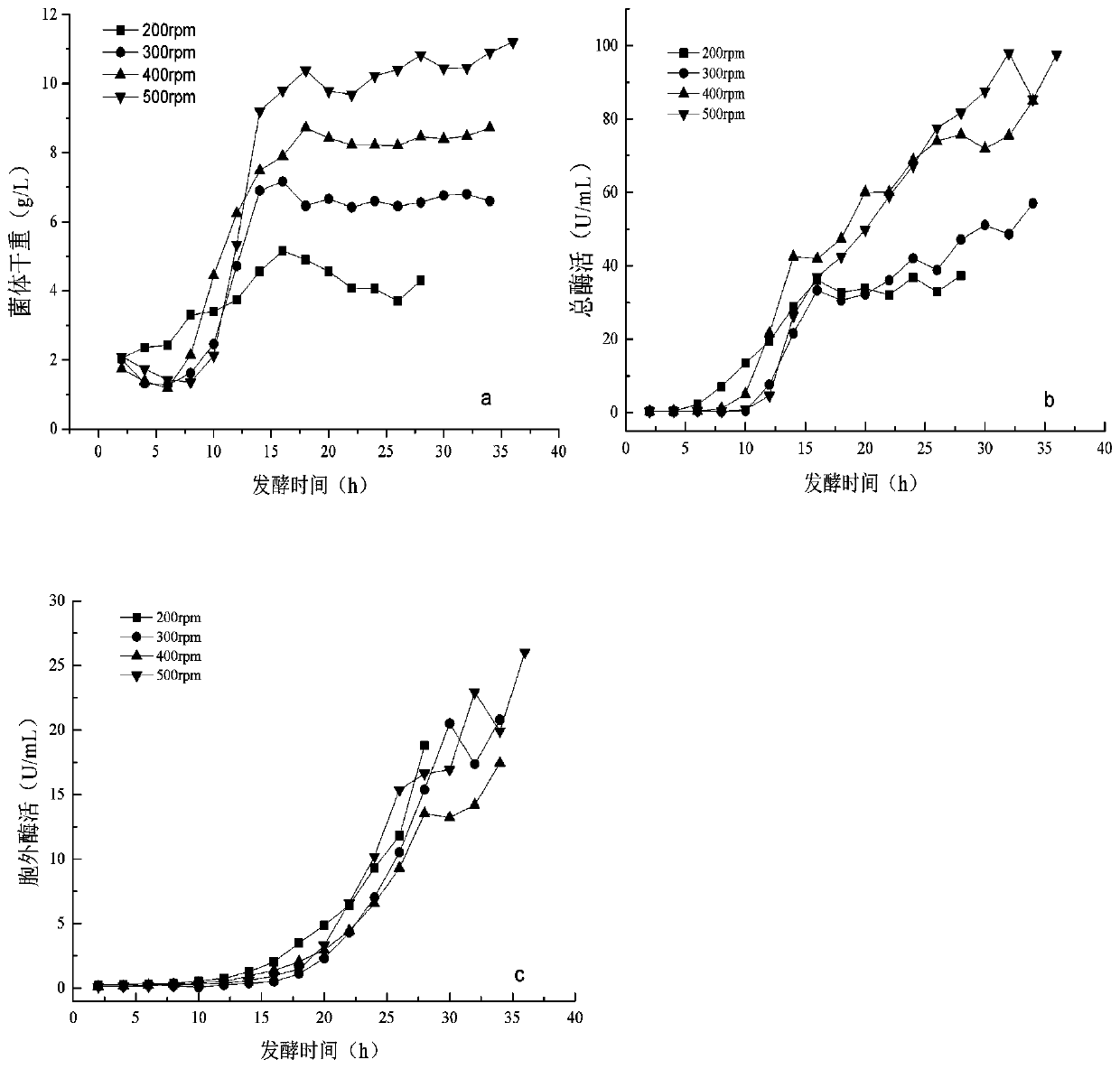

[0055] Example 1: Fermentation and cultivation of recombinant Bacillus subtilis under different rotating speed conditions

[0056] The recombinant Bacillus subtilis stored in a glycerol tube at -40°C was inserted into the seed medium, and cultured on a rotary constant temperature shaker with a speed of 220r / min and a culture temperature of 37°C for 20 hours. Insert the seed liquid into a 5L fermenter equipped with 3L fermentation medium with an inoculum of 5%, feed sterile air during the fermentation process, the ventilation rate is 1.5vvm, the fermentation temperature is 37°C, pH7.0, stirring speed Set 200rpm, 300rpm, 400rpm, 500rpm respectively, and the fermentation time is 36h. During the fermentation process, samples were taken every 2 hours, and the dry weight of the bacteria, the activity of extracellular proline aminopeptidase and intracellular proline aminopeptidase were measured.

[0057] The results showed that the proline aminopeptidase activity increased from 38.0...

Embodiment 2

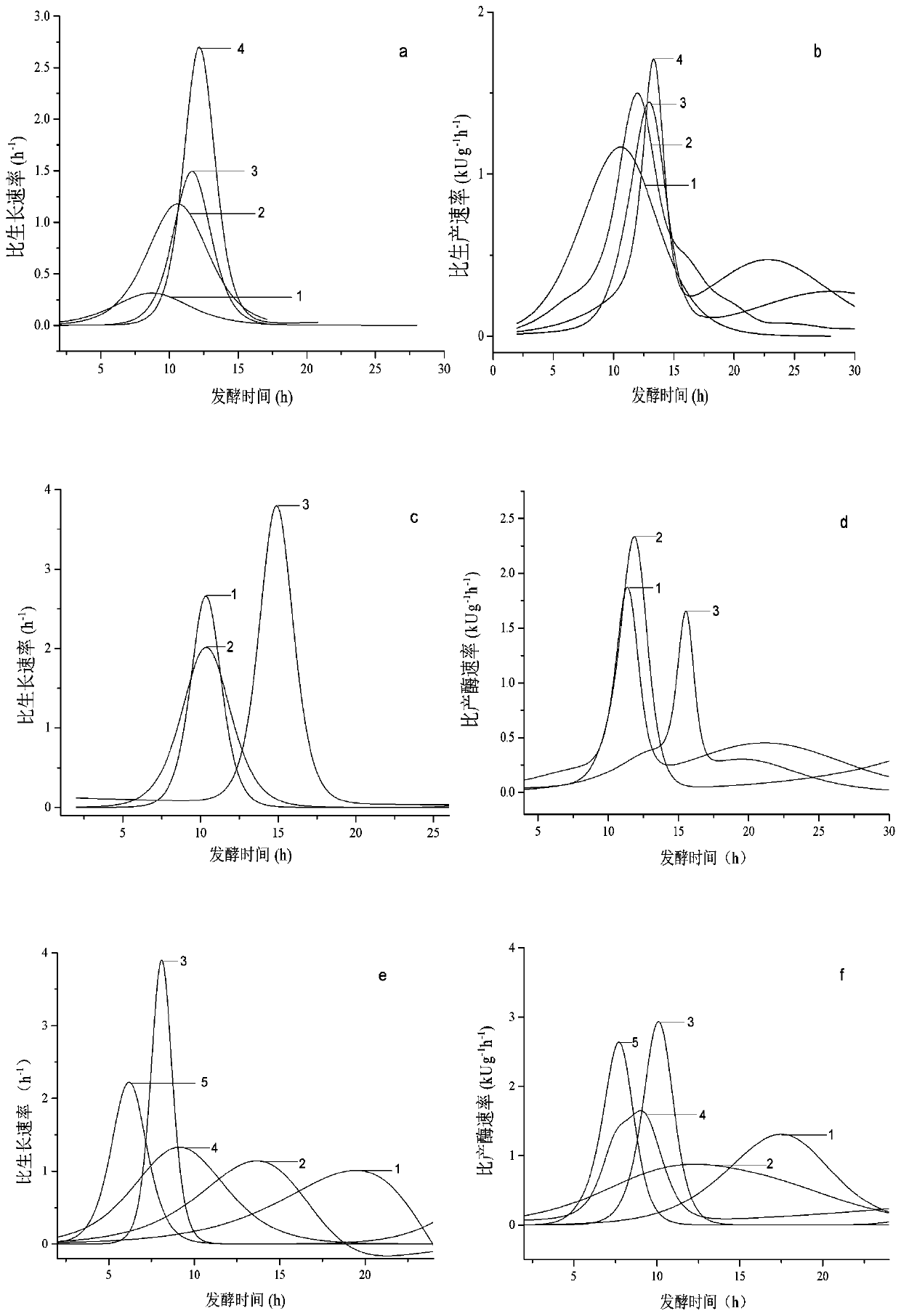

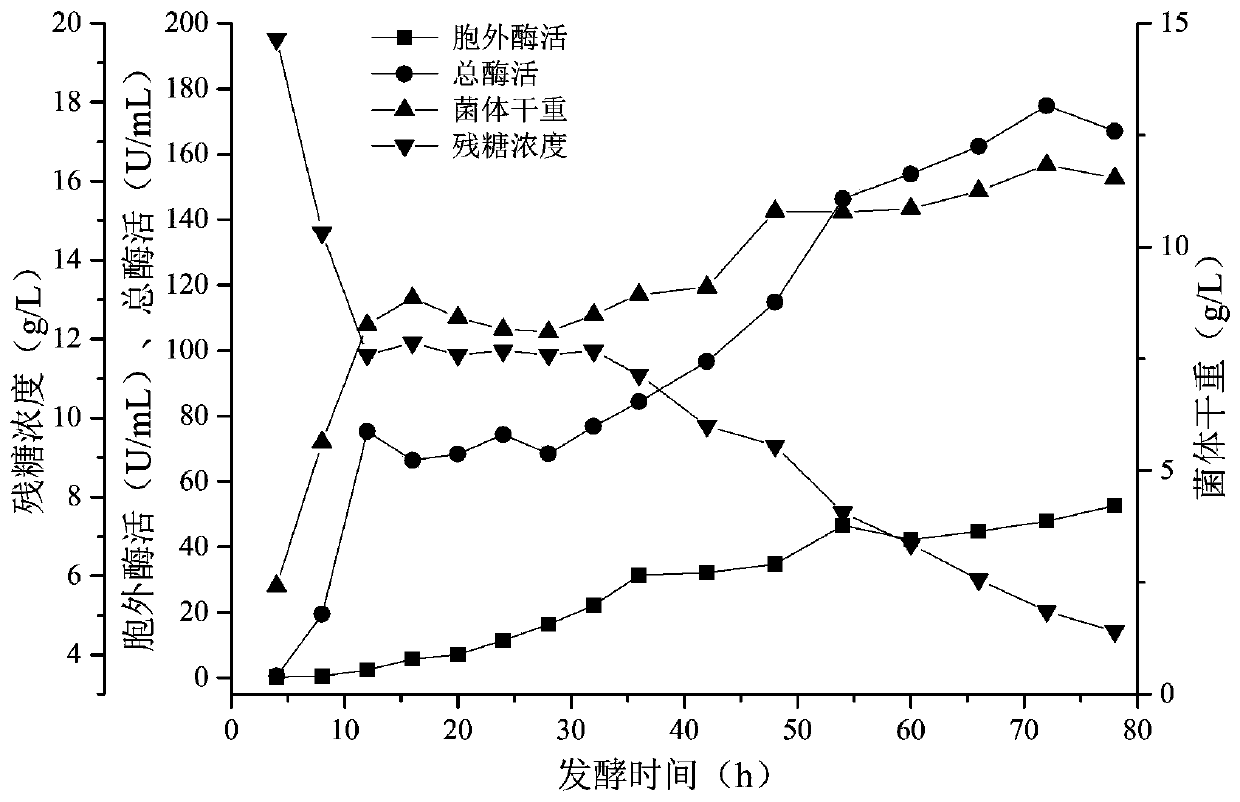

[0058] Embodiment 2: fermentation culture under the guidance of fermentation kinetics

[0059] Insert the seed liquid into a 5L fermenter with 3L fermentation medium at an inoculum amount of 5%, feed sterile air during the fermentation process, the ventilation rate is 1.5vvm, and the fermentation conditions: the speed control is 0-6h 200rpm, 6 -12h is 400rpm, 12-28h is 500rpm, 28h to the end of fermentation is 400rpm; pH regulation is 0-12h without controlling pH, 12-16h is pH7.0, 16-28hpH is not controlled, and pH7.0 after 28h; temperature The regulation is 8h before fermentation at 40°C, 35°C for 8-12h, and 33°C from 12h to the end of fermentation. During the fermentation process, samples were taken every 4 hours to measure the dry weight of the bacteria, the activity of extracellular proline aminopeptidase and intracellular proline aminopeptidase, etc.

[0060] The results showed that the fermentation strategy under kinetic analysis could significantly increase the yield o...

Embodiment 3

[0061] Embodiment 3: the effect of recombinant subtilis proline aminopeptidase in rice proteolysis

[0062] Prepare a 5% rice protein solution with pure water buffer, adjust the pH to 9.0 with 2M NaOH solution, keep it warm in a water bath at 90°C for 30 minutes, after cooling, add 15000U / g rice protein alkaline protease, react at 50°C for 4 hours, and boil for 15 minutes in a water bath After cooling, continue to add 3000U / g rice protein leucine aminopeptidase powder, react at 50°C for 2h, boil water bath for 15min, add 200U / g rice protein recombinant proline aminopeptidase enzyme solution after cooling, 50°C Reaction for 2 hours, boiling water bath for 15 minutes, cooling, the hydrolyzate mainly exists in the form of small peptides and free amino acids, the content of small peptides below 180Da reaches 44.70%, fully hydrolyzed the exposed N-terminal proline residues, free proline The acid content is 0.149 mg / mL, which is 1064.3 times the content of unhydrolyzed free proline....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com