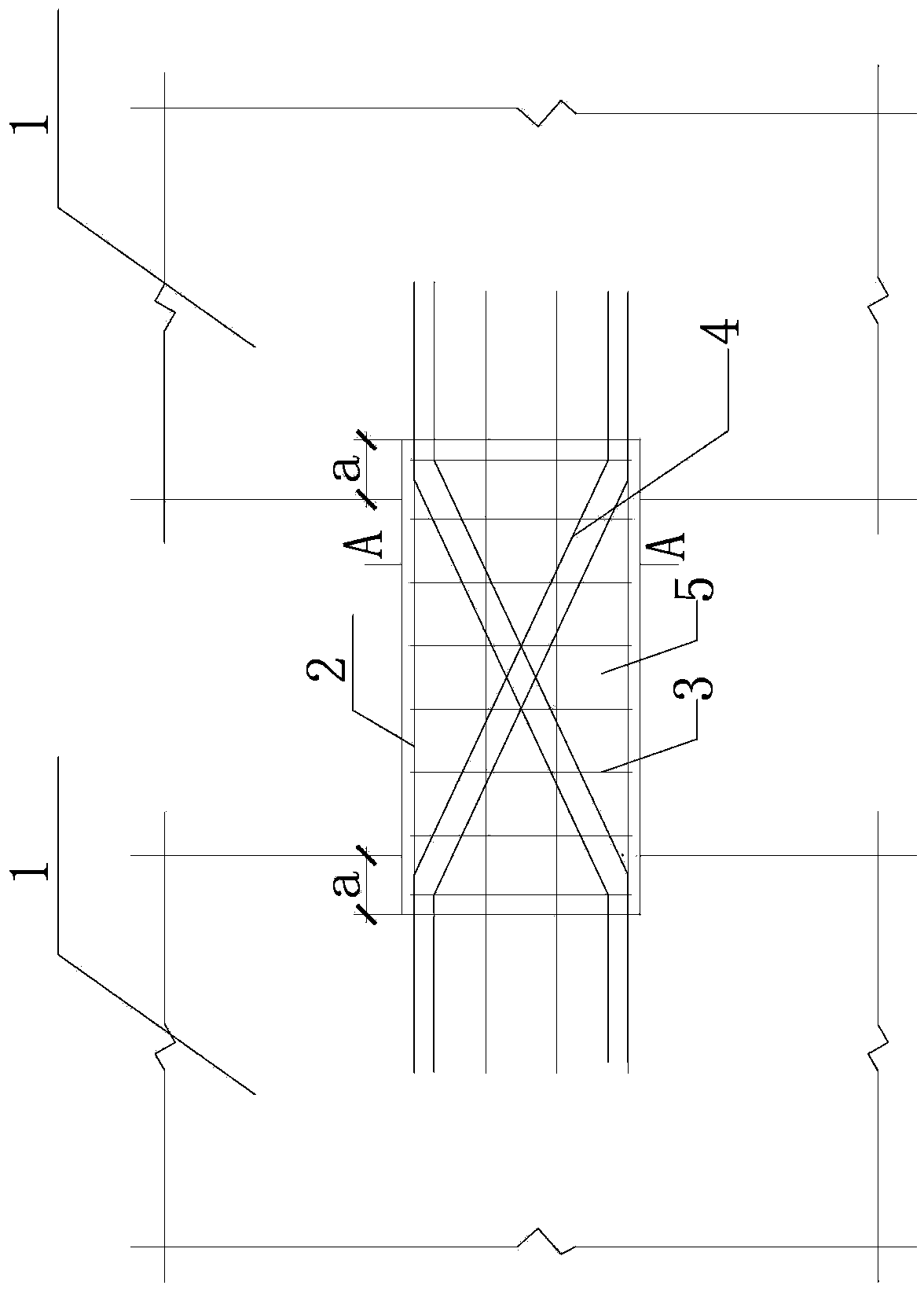

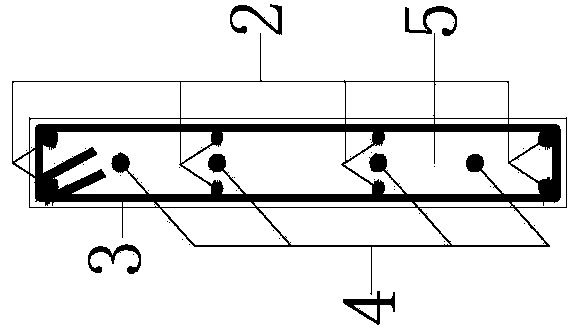

High-ductility coupled shear wall

A high-ductility, shear wall technology, applied in the direction of walls, building components, buildings, etc., can solve cable-stayed and baroclinic failures, slip shear failures along construction joints, buckling of stressed steel bars, and it is difficult to ensure The anti-seismic and shear capacity of the plastic hinge area of the shear wall cannot meet the requirements of the anti-seismic performance, so as to reduce the self-weight, reduce the difficulty of construction, and avoid the effect of repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

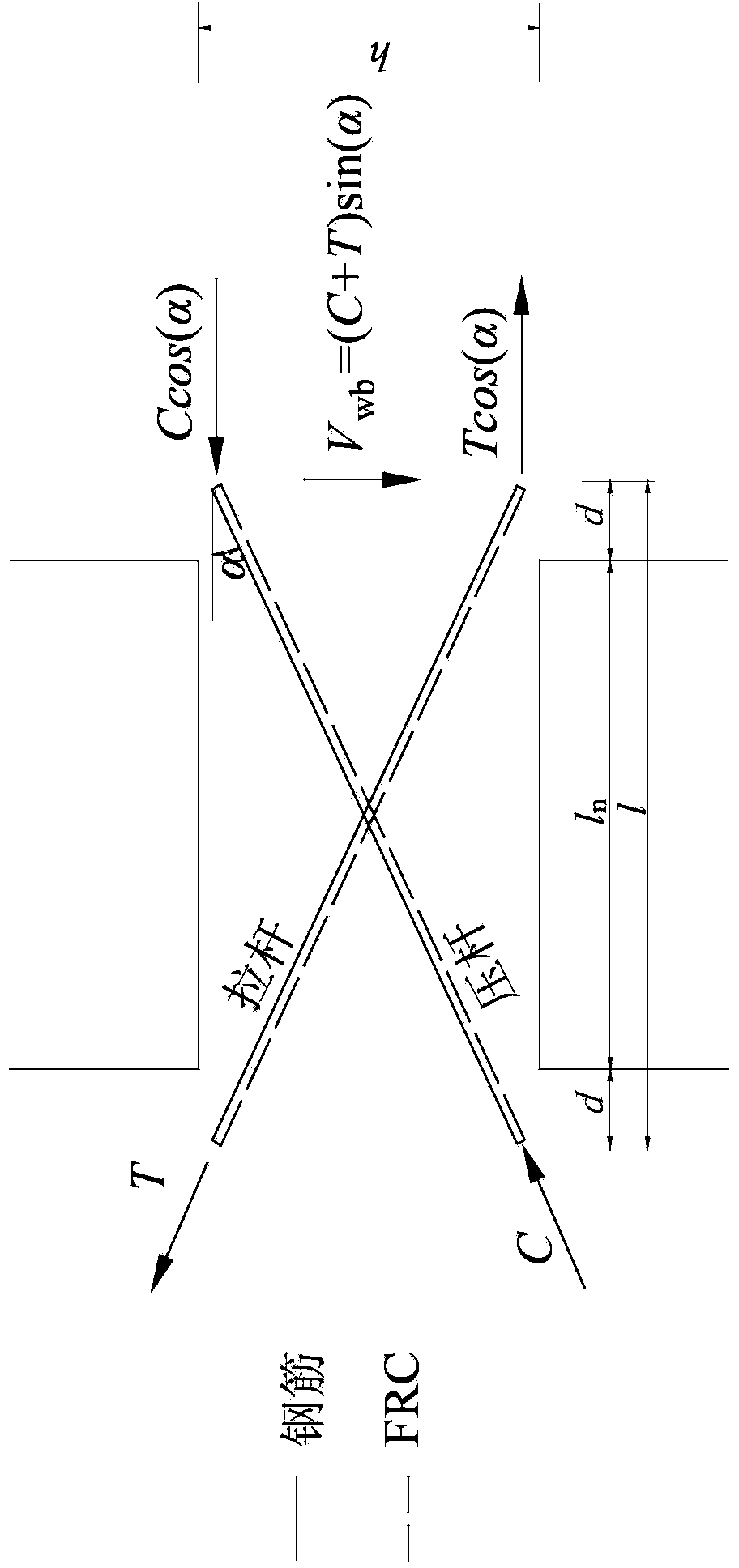

[0036] High ductility fiber concrete is a cement-based composite material in which randomly distributed short fibers are added to the cement matrix and designed through the interface. The fiber types include steel fibers, carbon fibers, and polymer fibers. It has a great ability to absorb energy, and the biggest difference from ordinary fiber concrete is that only about 2% of fibers are added, and its uniaxial tensile strain can reach 3%, and quasi-strain hardening occurs when stretched. There is a good coordinated deformation ability between ductile high-performance concrete and steel bars, and the bond-slip deformation of steel bars is small. Existing technologies show that about 1 ton of CO is emitted for every 1 ton of cement clinker produced 2 and other harmful gases, ductile high-performance concrete uses industrial waste (fly ash) to replace part of the cement clinker (about 50% to 70%), reducing the emission of harmful gases. The interface design of ductile high-perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com