Blast furnace smelting expert system built based on pattern recognition technology and method thereof

A blast furnace smelting and pattern recognition technology, applied in general control systems, control/regulation systems, instruments, etc., can solve the problems of low system learning and maintenance ability, difficulty in software development, lack of evaluation standards, etc., and achieve the ability to solve learning and maintenance. Low, the effect of improving maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

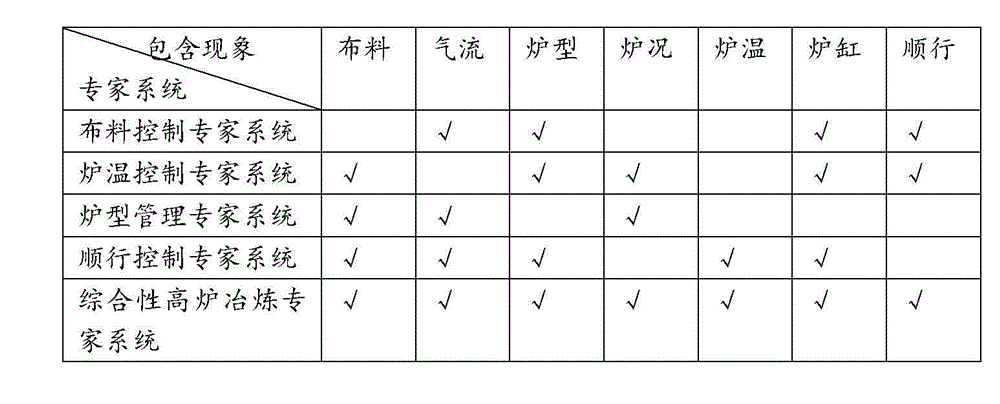

[0029] The present invention will be further described below in conjunction with the tables. When building a blast furnace smelting expert system based on pattern recognition technology, the content of the expert system itself is different with the difference in blast furnace control objectives. The following table lists the blast furnace process control expert system based on different purposes and the modes it contains identified content.

[0030]

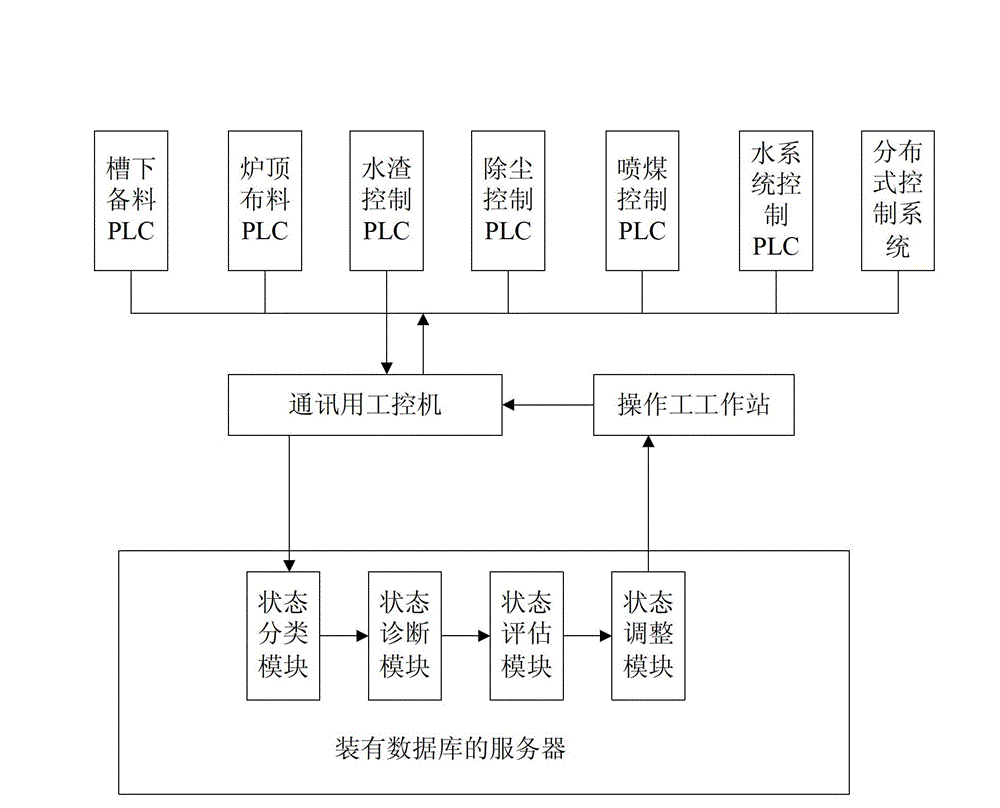

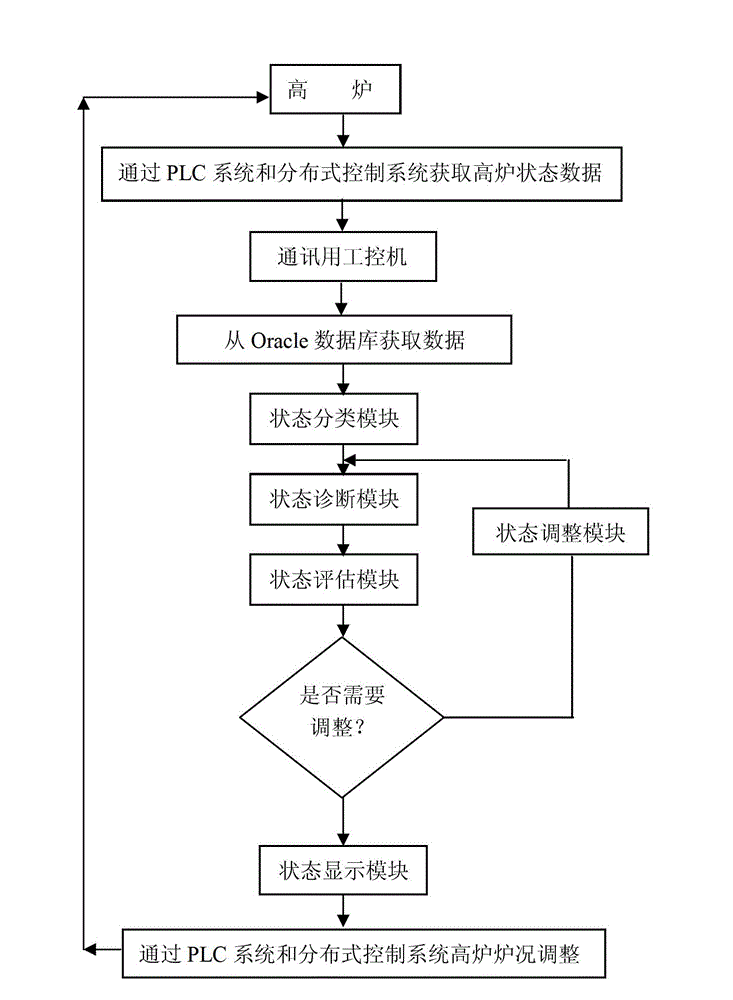

[0031] see figure 1 , the blast furnace smelting expert system constructed based on the pattern recognition technology of the present invention includes a server equipped with a database, an operator workstation, a PLC for preparing materials under the tank, a PLC for furnace roof distribution, a water slag contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com