Ridging sowing method for improving corn yield of saline-alkali soils

A saline-alkaline land and corn technology, applied in the field of corn sowing in saline-alkaline land, can solve the problem of low corn yield, achieve the effects of increased corn yield, enhanced salt washing effect, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

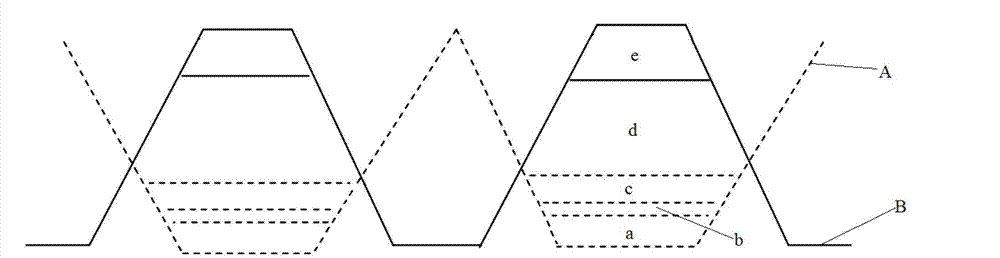

[0007] Specific embodiment one: this embodiment is a kind of ridge sowing method that improves the yield of corn in saline-alkali land, specifically completes according to the following steps: 1. Deep tillage and ridging: carry out deep tillage and ridging on April 25th to April 30th, The depth of the furrow is 20cm~25cm, and the width of the furrow is 15cm~20cm; 2. Application of improver: after deep plowing and ridge formation, phosphogypsum is evenly spread in the furrow as a modifier, and the amount of phosphogypsum applied is 40 kg / mu~80 kg / mu, then cover soil, the cover soil thickness is 3cm ~ 5cm; Three, base fertilizer application: first the mixed base fertilizer obtained by mixing conventional corn base fertilizer and commercial organic fertilizer is evenly spread on the cover soil layer obtained in step 2, in the described mixed base fertilizer The application rate of conventional corn base fertilizer is 30 kg / mu~40 kg / mu, and the application rate of commercial orga...

specific Embodiment approach 2

[0013] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the conventional corn base fertilizer described in the step 3 is a special compound fertilizer for corn or a compound fertilizer mixed by urea, diammonium phosphate and potassium sulfate; If the corn special compound fertilizer is used as the conventional corn base fertilizer, the application rate of the corn special compound fertilizer is 30 kg / mu~40 kg / mu; if the compound fertilizer made of urea, diammonium phosphate and potassium sulfate is used as the conventional corn When the base fertilizer is used, the application rate of urea in the compound fertilizer is 10 kg / mu to 15 kg / mu, and the application rate of diammonium phosphate in the compound fertilizer is 8 kg / mu to 10 kg / mu. The application rate of potassium sulfate in the compound fertilizer is 6 kg / mu~8 kg / mu. Others are the same as the first embodiment.

[0014] N, P in the special compound fertilizer for corn de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com