Slag carry-over detection method and device based on image recognition of vortex on surface of molten steel

A detection method and image recognition technology, applied in the direction of manufacturing tools, casting melt containers, casting equipment, etc., can solve the problems of short service life, complex device structure, easy damage, etc., to improve accuracy and stability, improve Yield, the effect of controlling the quality of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

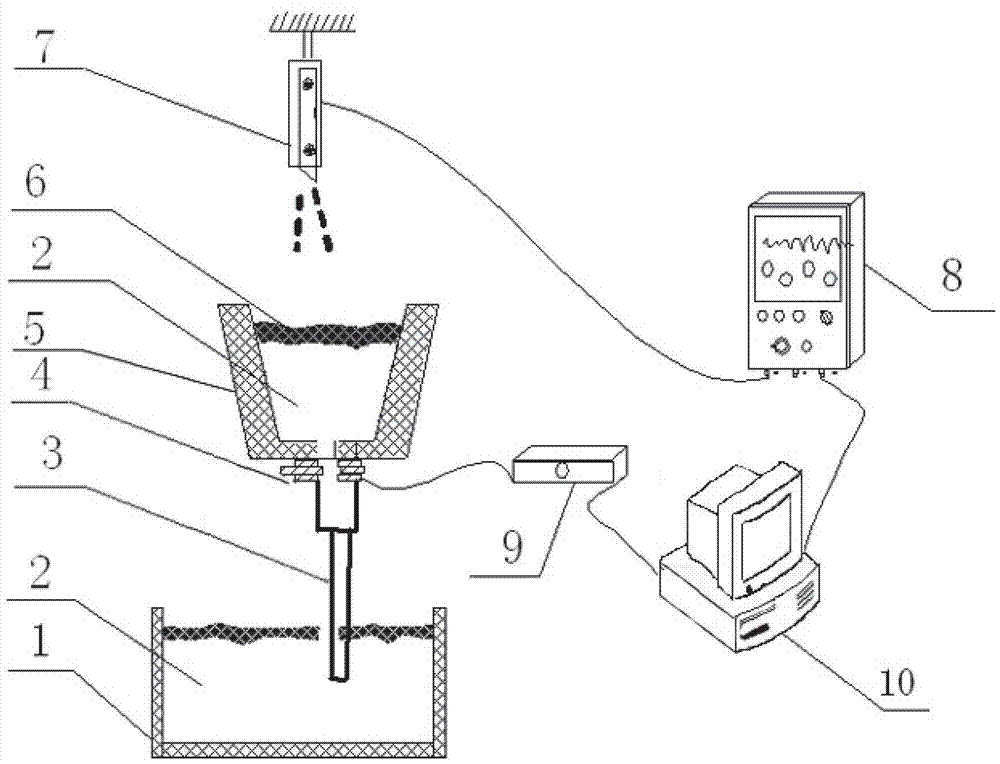

[0033] figure 1 The hardware composition of the slag detection device based on the vortex image recognition on the surface of molten steel 2 mainly includes an image acquisition system and an image processing system.

[0034] The image collection system is composed of a camera 7 for collecting image information of the liquid surface of the large bag 5 . Since the system is applied to the continuous casting production line, the installation site of the device has the characteristics of large dust, so it is necessary to add a dust cover to the outside of the camera 7 and seal it.

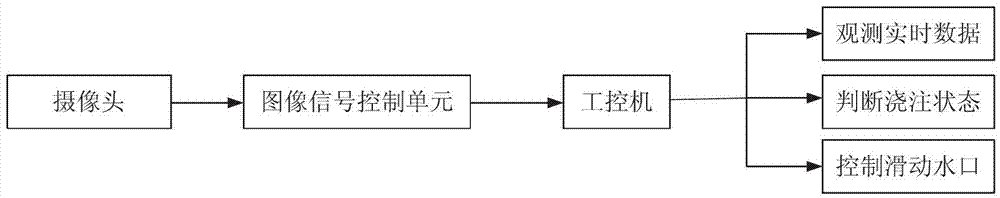

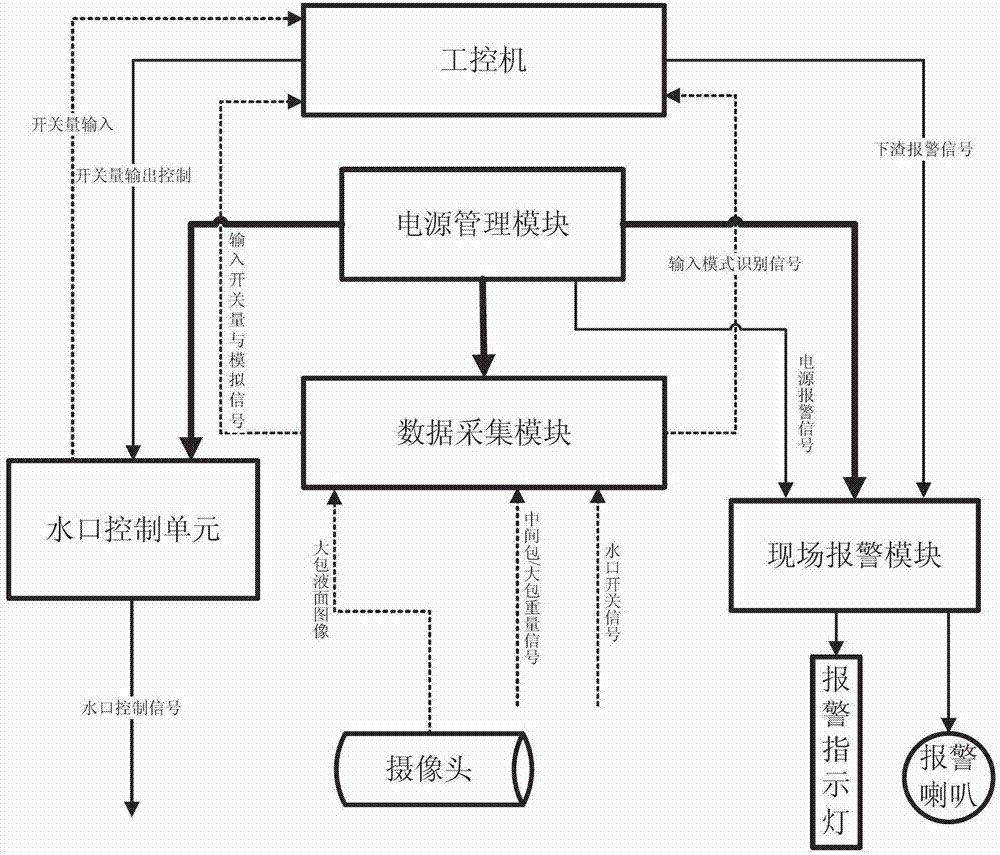

[0035]The image processing system includes an image signal control unit 8 and an industrial computer 10. The image signal control unit 8 integrates a data acquisition module, a power management module, a nozzle control unit 9 and an on-site alarm module. The data acqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com