Electromechanical brake driver of aircraft

A driver, electromechanical technology, applied in the direction of brakes, vehicle components, brake transmissions, etc., can solve the problems of heavy weight, complicated installation and disassembly, hydraulic oil leakage and combustion, etc., to reduce complexity, improve reliability, and enhance reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

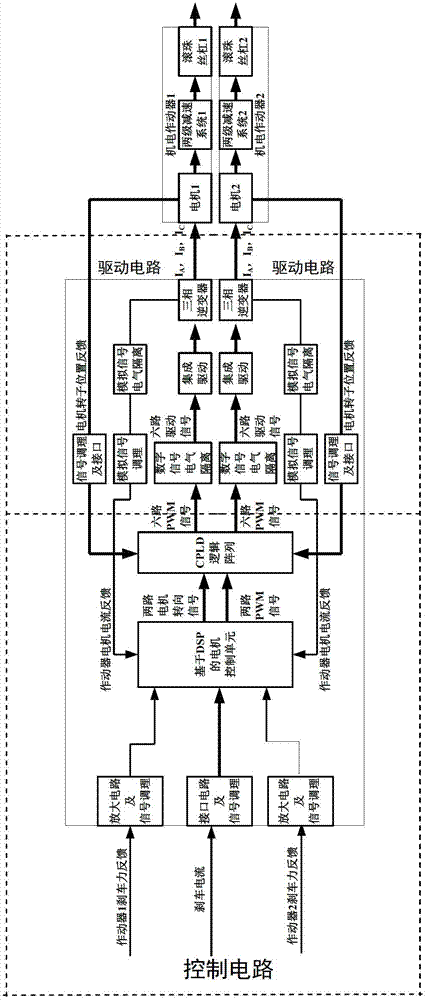

[0016] The invention is composed of a power supply circuit, a control circuit and a drive circuit. It is characterized in that the brake driver completely replaces the electro-hydraulic pressure servo valve and solenoid valve in the hydraulic brake system and changes the brake actuation mode.

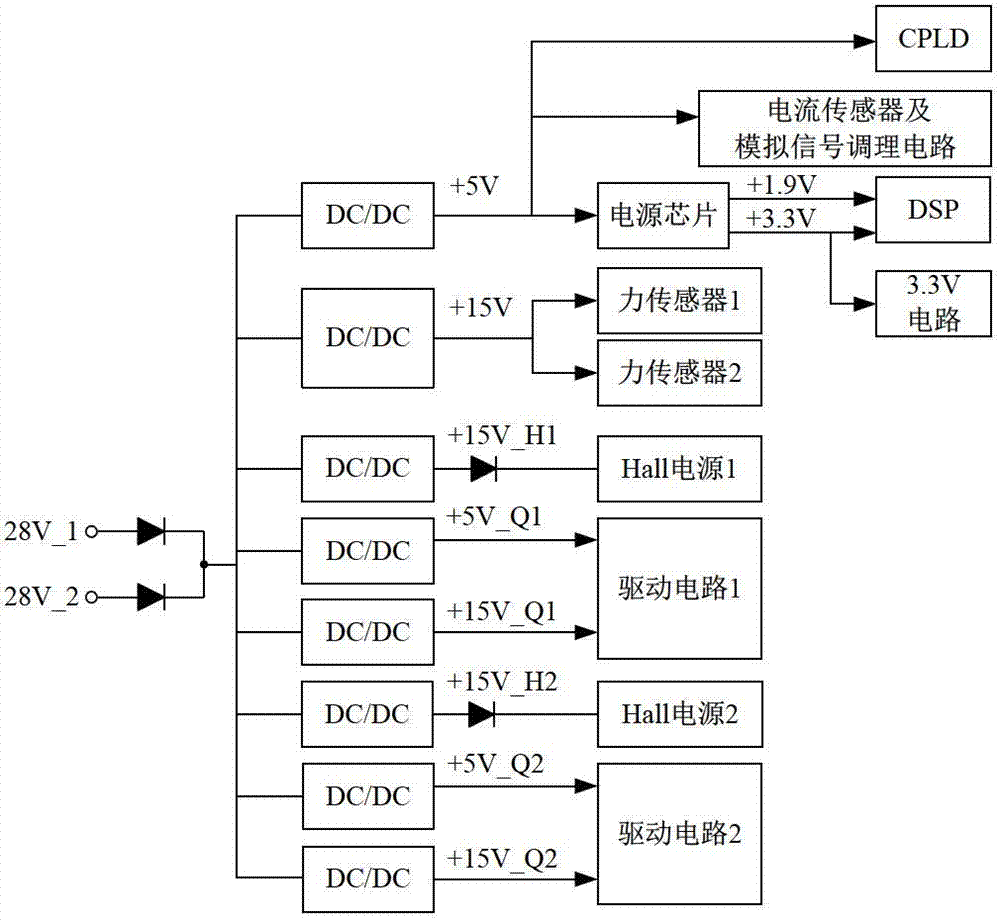

[0017] The power supply part of the brake driver is composed of a power filter and a DC-DC power module, which provides 15V and 5V power supplies for the control board of the brake driver, the sensor on the wheel of the brake main engine, and the drive circuit, and provides 15V working voltage.

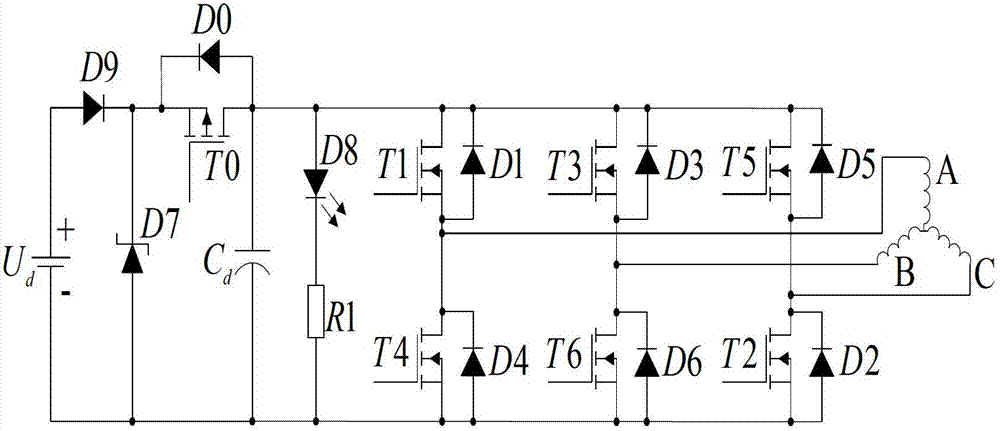

[0018] The control circuit is mainly composed of the control chip DSP minimum system and CPLD devices. The main function of the DSP is to receive the command braking force signal and the force feedback signal of the force sensor. After the DSP synthesizes these two signals, it passes the classic PI control algorithm and outputs the It is used to control the PWM signal of the brushless DC motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com