Reduction hydrogen production compound furnace and device and method for ammonium paratungstate tungsten production by using same

A technology of ammonium paratungstate and hydrogen production equipment, which is applied in the field of tungsten powder production, can solve problems affecting product quality and purity, product secondary pollution, power consumption and labor costs, etc., to reduce equipment investment and labor, save production procedures, and save The effect of electricity bills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

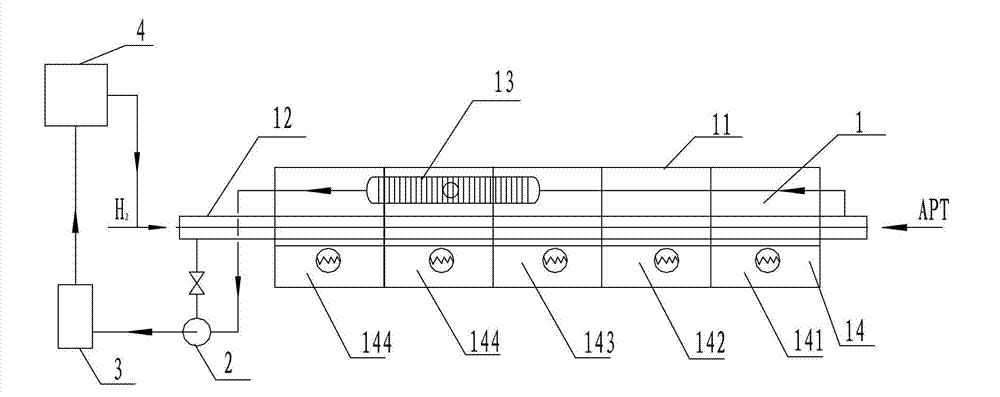

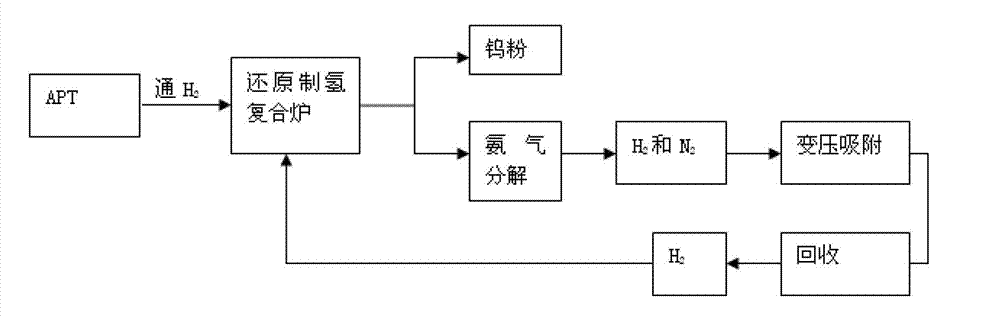

[0021] like figure 1 As shown, the device for producing tungsten from ammonium paratungstate in this embodiment includes a reduction hydrogen production composite furnace 1, a water cooler 2, a steam-water separator 3 and a hydrogen purification device 4, and the reduction hydrogen production composite furnace 1 includes a furnace body 11 and is arranged on the furnace body 11. The furnace tube 12, hydrogen production equipment 13 and heating equipment 14 inside, the heating temperature zone of the heating equipment 14 is 700°C-900°C, and the heating temperature zone includes 700°C temperature zone 141, 800°C tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com