Sulphoaluminate-base high-strength grouting concrete and preparation method thereof

A technology of sulphoaluminate and grouting material, which is applied in the field of concrete, can solve the problems of unfavorable resistance, settlement, and low flexural strength, and achieve the goals of inhibiting later strength shrinkage, stabilizing micro-expansion performance, and saving energy costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Anhydrite, limestone, and sulfur-aluminum clinker are crushed separately, passed through a 60-mesh sieve, and 15kg of anhydrite powder passed through a 60-mesh sieve, 10kg of limestone, and 70kg of sulfur-aluminum clinker are added to the grinder and ground until the specific surface area is 450cm 2 / g, stop grinding, transfer to a homogenizer, homogenize for 15 minutes, transfer to a high-speed mixer, add 100kg of aggregate (quartz sand), 0.4kg of plasticizer (polycarboxylate superplasticizer), Anti-settling agent 0.07kg (cellulose ether), defoamer 0.1kg (non-ionic surfactant, nonylphenol polyoxyethylene ether) and coagulation regulator (boric acid) 0.3kg, mix well to obtain sulfoaluminate base High-strength grouting material.

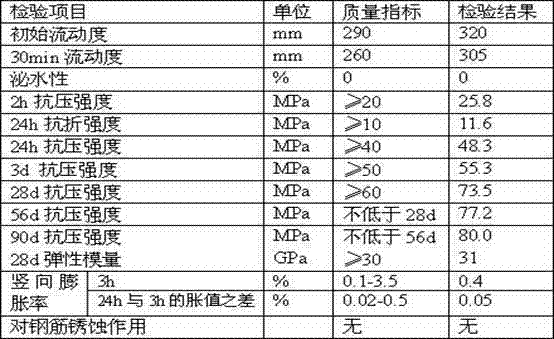

[0049] Table 1 is the performance test result of embodiment 1 gained product:

[0050] Table 1:

[0051]

Embodiment 2

[0053] Anhydrite, limestone, and sulfur-aluminum clinker are crushed separately, passed through a 60-mesh sieve, and 15.3kg of anhydrite powder passed through a 60-mesh sieve, 10.3kg of limestone, and 71.4kg of sulfur-aluminum clinker are added to the grinder and ground until the specific surface area is 450cm2 / g, stop grinding, transfer to a homogenizer, homogenize for 15 minutes, transfer to a high-speed mixer, add 96kg of aggregate (quartz sand and gravel mixed at 1:1), plasticizer 0.5kg (polycarboxylic acid Salt superplasticizer), anti-settling agent 0.08kg (cellulose ether), defoamer (octylphenol polyoxyethylene ether) 0.14kg and coagulation regulator (citric acid) 0.36kg, mix evenly to obtain sulfoaluminic acid Salt-based high-strength grouting material.

[0054] Table 2 is the performance test result of the product obtained in embodiment 2:

[0055] Table 2:

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com