Hexagonal crystal M+W mixed type sintered permanent magnetic ferrite magnet and preparation method thereof

A technology of permanent magnet ferrite and hexagonal crystal, which is applied in the field of hexagonal crystal M+W mixed sintered permanent ferrite magnet and its preparation, can solve the problems that it is difficult to expect a dramatic increase in magnetic performance, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

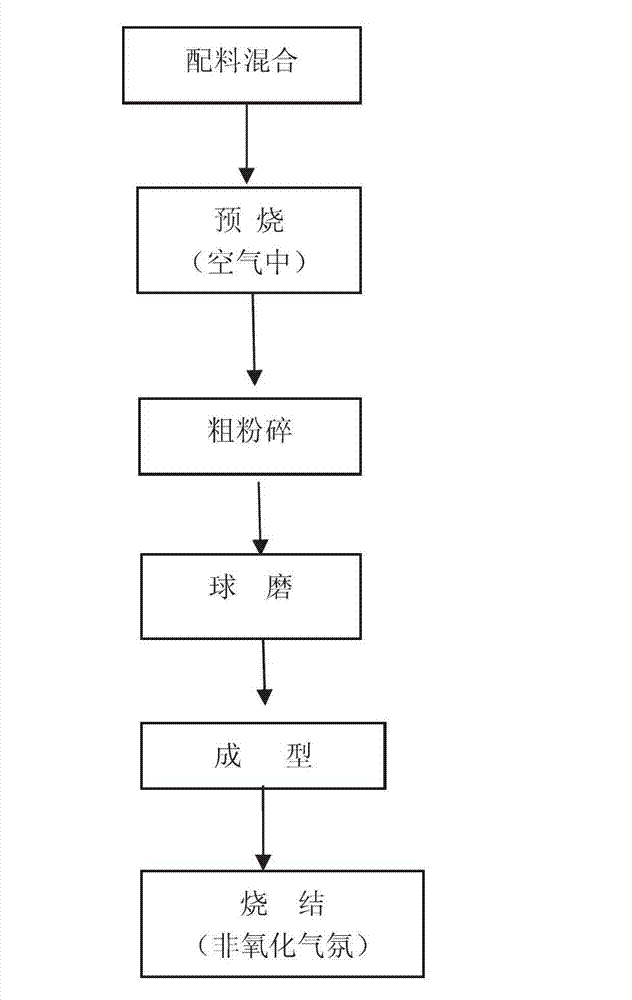

Method used

Image

Examples

Embodiment 1

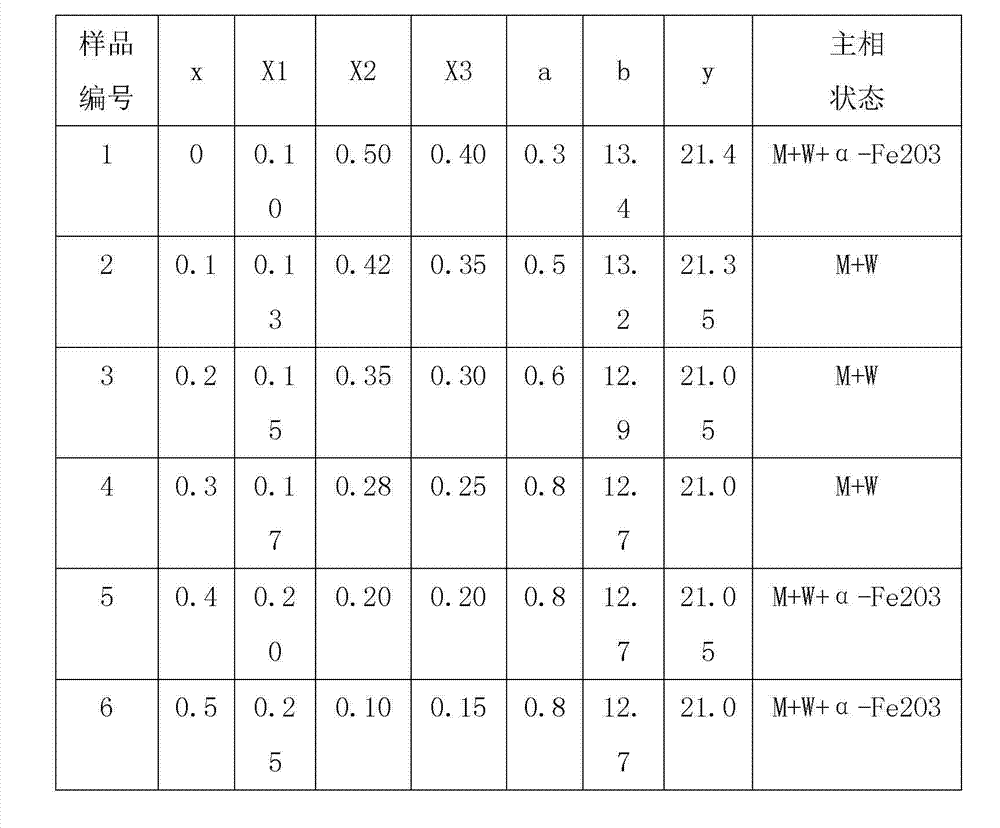

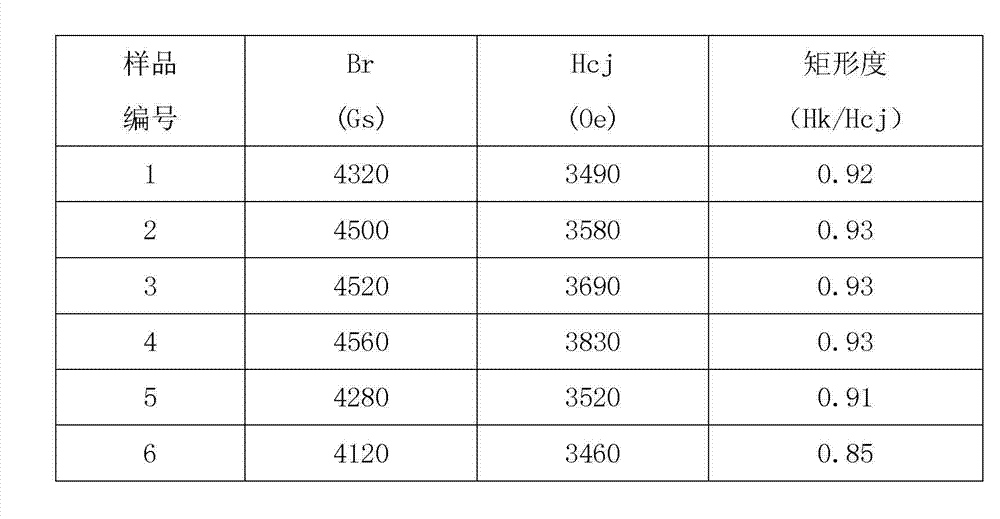

[0041] Research on the amount of La added:

[0042] Weigh the specified amount of iron oxide (Fe 2 o 3 ) powder (purity ≥ 99.0wt%, original average particle size of particles: 0.7 ~ 1.0μm), calcium carbonate (CaCO 3 ) powder, (purity ≥ 98.5wt%, original average particle size of particles: 2.0-5.0μm), strontium carbonate (SrCO 3 ) powder (purity ≥ 98.5wt%, original average particle size of particles: 1.0-2.0μm), barium carbonate (BaCO 3 ) powder (purity ≥ 98.5wt%, original average particle size of particles: 1.0-2.0μm), lanthanum oxide (La 2 o 3 ) powder (purity ≥ 99.0wt%, original average particle size of particles: 2.0 ~ 5.0μm), add 0.3wt% SiO to the above mixture 2 Powder (purity ≥ 98.0wt%, original average particle size of particles: 1.0μm), 0.1wt% H 3 BO 3Powder (purity ≥ 99.0wt%) and wet mixing, the average particle size of the mixture after mixing is 0.9μm. After the mixture was dried, it was prefired at 1280° C. in the atmosphere for 2 hours.

[0043] The obtai...

Embodiment 2

[0055] Mole study of iron:

[0056] Using the same iron oxide (Fe 2 o 3 ) powder, calcium carbonate (CaCO 3 ) powder, strontium carbonate (SrCO 3 ) powder, barium carbonate (BaCO 3 ) powder and lanthanum oxide (La 2 o 3 ) powder, formulated into Ca x1 Sr x2 Ba x3 La x Fe 2+ a Fe 3+ b The composition of Oy (where x1=0.15, x2=0.35, x3=0.3, x=0.2, a+b=11.5, 12.5, 13.5, 14.5 and 15.5). Add 0.3wt% SiO to the above mixture 2 powder, 0.1wt% H 3 BO 3 Powder and wet mixing, the average particle size of the mixture is 0.9μm. After the mixture was dried, it was prefired at 1280° C. in the air for 2 hours.

[0057] The obtained calcined material particles are subjected to dry coarse pulverization in a vibration mill to obtain a coarse powder with an average particle size of 3.0-5.0 μm.

[0058] Then, take 500 grams of the above-mentioned coarse powder, add 0.25wt% SiO 2 , 0.60wt% CaCO 3 , 0.80wt% Cr 2 o 3 , 0.10wt% H 3 BO 3 , 0.25wt% Al 2 o 3 , 0.20wt% ZnO, ...

Embodiment 3

[0070] Study on sintering atmosphere and carbon black addition:

[0071] Using the same iron oxide (Fe 2 o 3 ) powder, calcium carbonate (CaCO 3 ) powder, strontium carbonate (SrCO 3 ) powder, barium carbonate (BaCO 3 ) powder and lanthanum oxide (La 2 o 3 ) powder, formulated into Ca x1 Sr x2 Ba x3 La x Fe 2+ a Fe 3+ b The composition of Oy (x1=0.15, x2=0.35, x3=0.3, x=0.2, a+b=13.5). Add 0.3wt% SiO to the above mixture 2 Powder (purity ≥ 98.0wt%, original average particle size of particles: 1.0μm), 0.1wt% H 3 BO 3 Powder (purity ≥ 99.0wt%) and wet mixing, the average particle size of the mixture is 0.9μm. After the mixture was dried, it was prefired at 1280° C. in the air for 2 hours.

[0072] The obtained calcined material particles are subjected to dry coarse pulverization in a vibration mill to obtain a coarse powder with an average particle size of 3.0-5.0 μm.

[0073] Then, take 5 parts of each 500 grams of above-mentioned coarse powder material, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com