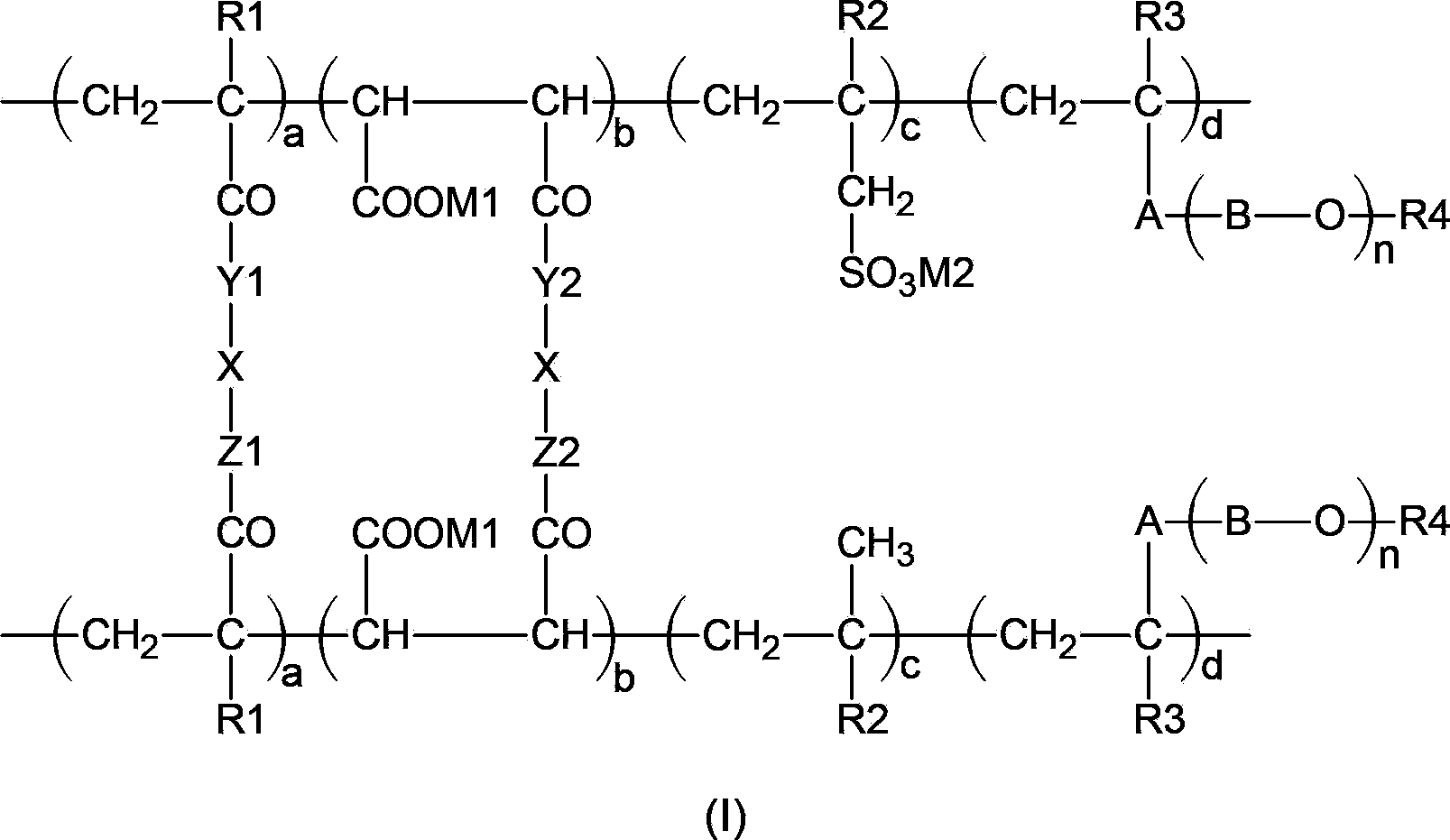

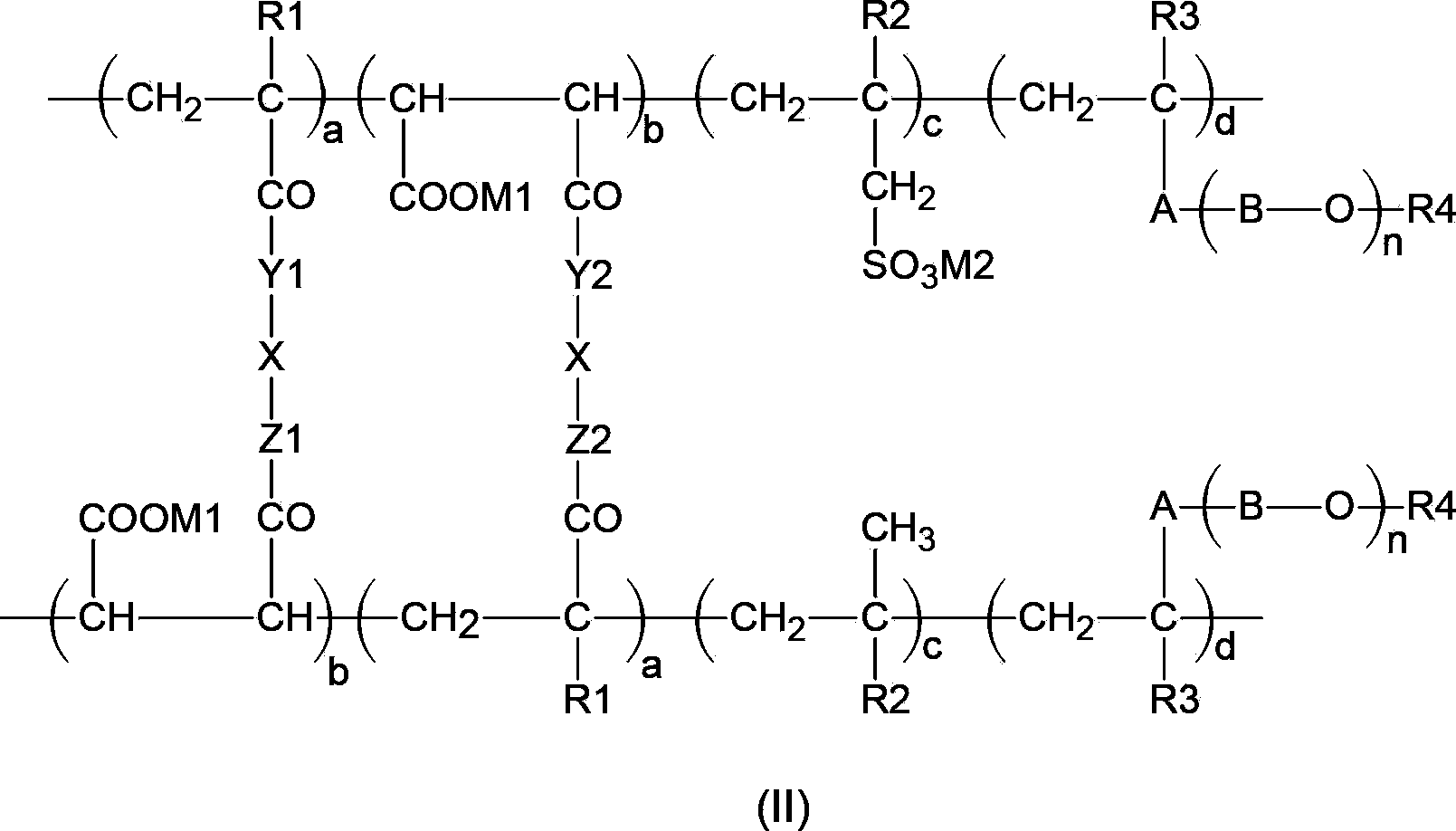

Amido crosslinked poly-carboxylic acid compound as well as production method and application thereof

A technology of carboxylic acid compound and polyamine compound, which is applied in the field of water reducer and amide-based cross-linked polycarboxylic acid compound, can solve the problems of large environmental impact, difficulty in mixing operation and release control, and chemical slow-release type water reducer. Few reports of water preparations and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Add 300g of allyl polyethylene glycol with a molecular weight of 1000 and 50g of sodium methallylsulfonate into the reaction vessel, add 200g of water, stir and raise the temperature to 60-80°C, and at the same time start to drop 85g of acrylic acid and initiator persulfuric acid 45g of 10wt% sodium solution was added dropwise for 60-120 minutes. After the dropwise addition was completed, the reaction was continued for 120-180 minutes, and the heating was stopped.

[0049] Cool to 30-40°C, add 10g of propylenediamine, stir, start to drop 45g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide (EDC) solution and 4-dimethylaminopyridine (DMAP) solution 10g, the solution concentration is 1wt%, the dropping time is 30-60min, continue to react for 60min-120min after dropping, add NaOH solution with a mass fraction of 30% to adjust the pH value to 6-7; add water to dilute to mass Fraction 30%, promptly obtains amide cross-linked slow-release polycarboxylate superplasticizer.

Embodiment 2

[0051] Add 300g of polyethylene glycol monomethyl ether acrylate with a molecular weight of 1000 into the reaction vessel, add 200g of water, stir and raise the temperature to 60-80°C, add 4g of initiator sodium persulfate, and start to add acrylic acid dropwise after it is fully dissolved 85g and 40g of 10wt% solution of chain transfer agent thioglycolic acid (mass ratio of chain transfer agent to initiator: 1:1), dropwise for 60-120min, continue to react for 120-180min after dropping, stop heating.

[0052] Cool to 30-40°C, add 7.4g of propylenediamine, stir, start to drop 40g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide (EDC) solution and 4-dimethylamino Pyridine (DMAP) solution 10g, the solution concentration is 1wt%, the dropwise addition time is 30-60min, after the dropwise addition, continue to react for 60min-120min, add NaOH solution with a mass fraction of 30% to adjust the pH value to 6-7; add water to dilute to If the mass fraction is 30%, the amide-based cross...

Embodiment 3

[0054] Add 300 g of allyl polyethylene glycol with a molecular weight of 1000 and 50 g of sodium methallyl sulfonate into the reaction vessel, add 200 g of water, stir and heat up to 60-80 ° C, and start to drop 60 g of aqueous solution of maleic anhydride and Initiator sodium persulfate 10wt% solution 45g, dropwise adding time 30-60min, continue to react for 180-240min after dropping, stop heating.

[0055] Cool to 30-40 degrees Celsius, add 8g of propylenediamine, stir, start to drop 4.14g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide (EDC) solution and 4-dimethylamino Pyridine (DMAP) solution 10g, the solution concentration is 1wt%, the dropwise addition time is 30-60min, after the dropwise addition, continue to react for 60min-120min, add NaOH solution with a mass fraction of 30% to adjust the pH value to 6-7; add water to dilute to If the mass fraction is 30%, the amide-based cross-linked slow-release polycarboxylate superplasticizer can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com