Ink and preparation method thereof

A production method and ink technology, applied in ink, household utensils, applications, etc., can solve the problem that ink is not suitable for blackboard writing, and achieve the effect of preventing occupational diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1 of the present invention provides an ink, including 30%-40% phenolphthalein, 8%-15% thickener, 14%-20% white oil, 12%-15% glycerin, 10%-20% water, 8%~10% silicon dioxide, 5%~10% edible alcohol, 0.5%~1.5% sodium hydroxide.

[0057] Wherein, each percentage is weight percentage, and unless otherwise specified in this application document, all percentages are by weight percentage.

[0058] Preferably, as a possible embodiment, the specific proportion of the ink is: 30% phenolphthalein, 8% thickener, 20% white oil, 15% glycerin, 10% water, 8% silicon dioxide, 8% food Alcohol, 1% Sodium Hydroxide.

[0059] Preferably, as another possible embodiment, the specific proportion of the ink is: 37% phenolphthalein, 15% thickener, 10% white oil, 12% glycerin, 10% water, 10% silicon dioxide, 5% Edible alcohol, 1% sodium hydroxide.

[0060] Preferably, the thickener is an inorganic thickener and / or cellulose ether. For example, it can be fumed white carbon black, sodi...

Embodiment 2

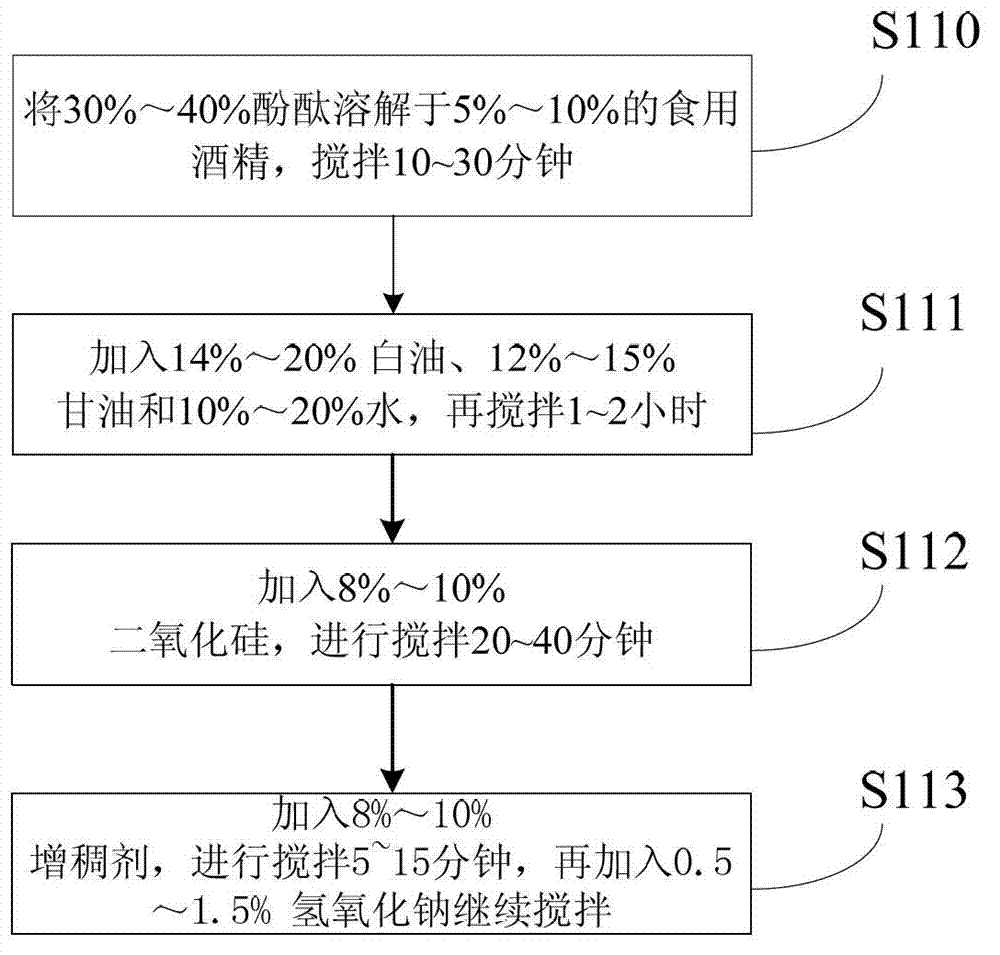

[0068] Embodiment 2 of the present invention provides a method for making ink, see figure 1 shown, including steps:

[0069] Step S110: Dissolving 30%-40% phenolphthalein in 5%-10% edible alcohol and stirring for 10-30 minutes.

[0070] Wherein the specific mass ratio of phenolphthalein and edible alcohol can be adjusted according to actual needs by those skilled in the art, and should be continuously stirred as much as possible during stirring, so that each solution component is fully mixed and dissolved, and the stirring time can also be adjusted by those skilled in the art according to actual needs The specific adjustment is not limited in the present invention.

[0071] Step S111: Add 14%-20% white oil, 12%-15% glycerin and 10%-20% water, and stir for another 1-2 hours.

[0072] The specific mass ratio of white oil, glycerin and water and the stirring time can also be adjusted by those skilled in the art according to actual needs, and the present invention does not enume...

Embodiment 3

[0077] Embodiment 3 of the present invention also provides a method for making ink, comprising the steps of:

[0078] Step S210: Dissolve 40% phenolphthalein in 5% edible alcohol, and stir for 20 minutes with a disperser.

[0079] Step S211: Add 14% white oil, 12% glycerin and 10% water, then disperse and stir for 1 hour.

[0080] Step S212: Add 8% silicon dioxide, and carry out dispersing and stirring for 30 minutes.

[0081] Step S213: Add 10% thickener, disperse and stir for 10 minutes, then add 1% sodium hydroxide and continue stirring.

[0082] In general, first dissolve 40% phenolphthalein by weight in 5% edible alcohol, stir continuously for 20 minutes with a disperser, add 14% white oil, 12% glycerin, and 10% water, and then disperse and stir for 1 hour , then add 8% silicon dioxide, then disperse and stir for 30 minutes, then add 10% thickener, then disperse and stir for 10 minutes, then add 1% sodium hydroxide and stir. In this way, qualified ink products are prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com