Saponin-containing composite type hydrate anti-agglomerant

A technology of anti-aggregation agent and hydrate, which is applied in the field of hydrate anti-aggregation agent and compound hydrate anti-aggregation agent. Coalescence and other problems, to avoid hydrate coalescence, solve the problem of flow safety guarantee, and achieve the effect of uniform particle distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] This embodiment provides a saponin plant extract, which is prepared by the following steps:

[0074] First, select 100g of the saponaria bark (the skin remaining after the fruit is removed from the saccharin sacchari pod), and grind the saponaria bark to powder with a pulverizer to obtain the saponaria powder;

[0075] Pour the saponin powder into the Soxhlet extractor, add 600g of absolute ethanol for 3 hours of extraction to obtain a mixed solution;

[0076] A Buchner funnel was used to suction and filter the mixed liquid, and the filtrate was distilled under reduced pressure using a rotary evaporator until solids precipitated out. The concentrated liquid obtained at this time was a saturated solution (brown liquid), that is, a saponin plant extract.

[0077] According to measurement, in the saponin plant extract extracted in this example, the total saponin content is 21% of the mass of saponin bark, and the effective concentration of saponin in the saponin plant extract is 19...

Embodiment 2

[0079] This embodiment provides a saponin plant extract, which is prepared by the following steps:

[0080] Select 100g of licorice and grind it to powder in a mortar to obtain licorice powder;

[0081] Pour the licorice powder into the flask, add 300g of water to leaching at 70°C for 4 hours, use a Buchner funnel for suction filtration, and again use 300g of water for 4 hours of leaching of the filter residue. Suction filtration is repeated. Filter four times to obtain a mixed liquid, the mixed liquid is the sum of the liquid obtained by the four immersion;

[0082] Filter the mixed liquid, concentrate the filtrate and evaporate the water in it by a vacuum distillation method to obtain the saponin plant extract solid;

[0083] The above-mentioned solid is dissolved in absolute ethanol and then concentrated until the solid is precipitated. The concentrated liquid at this time is the saponin plant extract.

[0084] After measurement, in the saponin plant extract extracted in this exampl...

Embodiment 3

[0086] This embodiment provides a saponin-containing composite hydrate anti-polymerization agent, which is prepared by the following steps:

[0087] The saponin plant extract extracted in Example 1 and the auxiliary anti-polymerization agent Span20 were mixed according to a mass ratio of 3:1 and stirred uniformly to obtain a saponin-containing composite hydrate anti-polymerization agent.

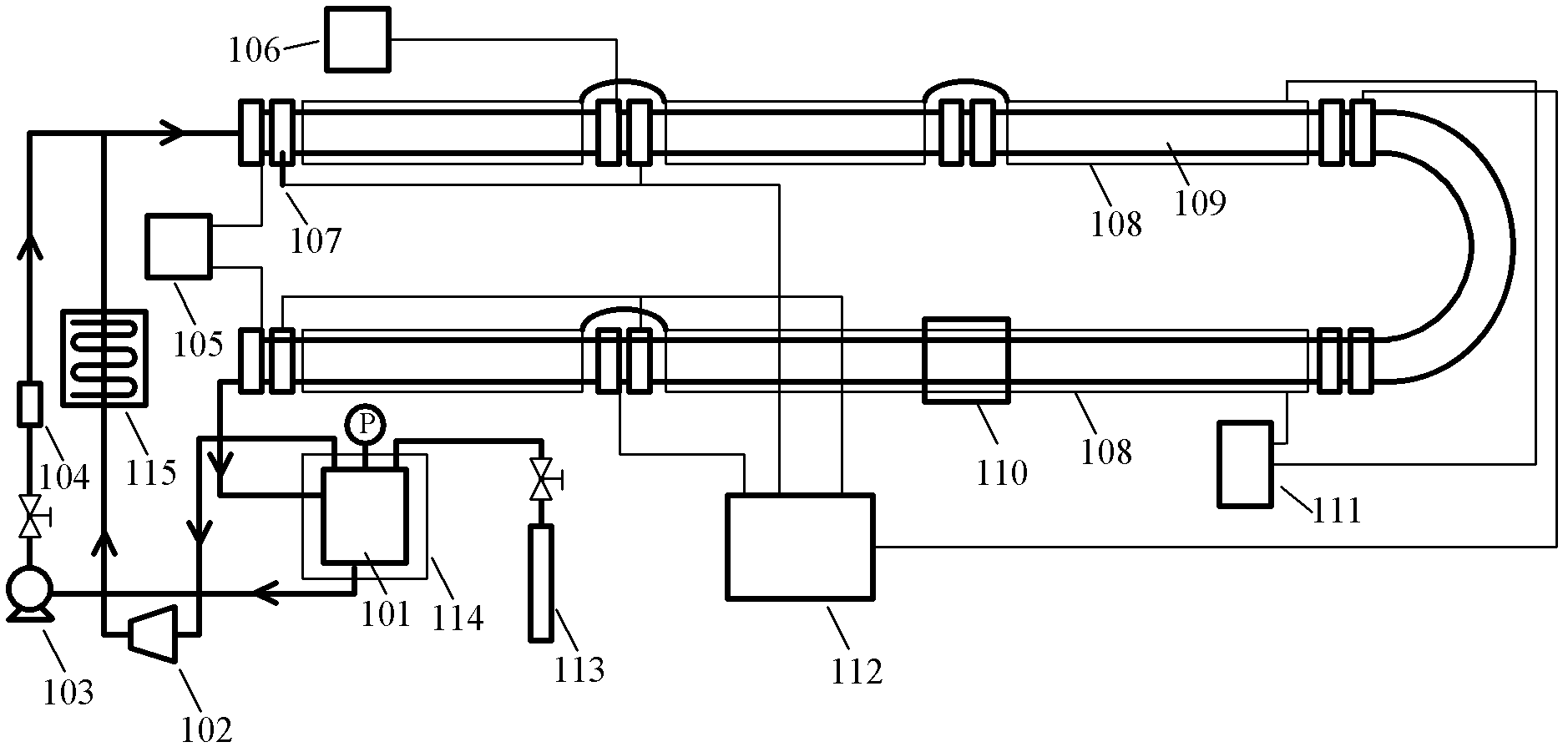

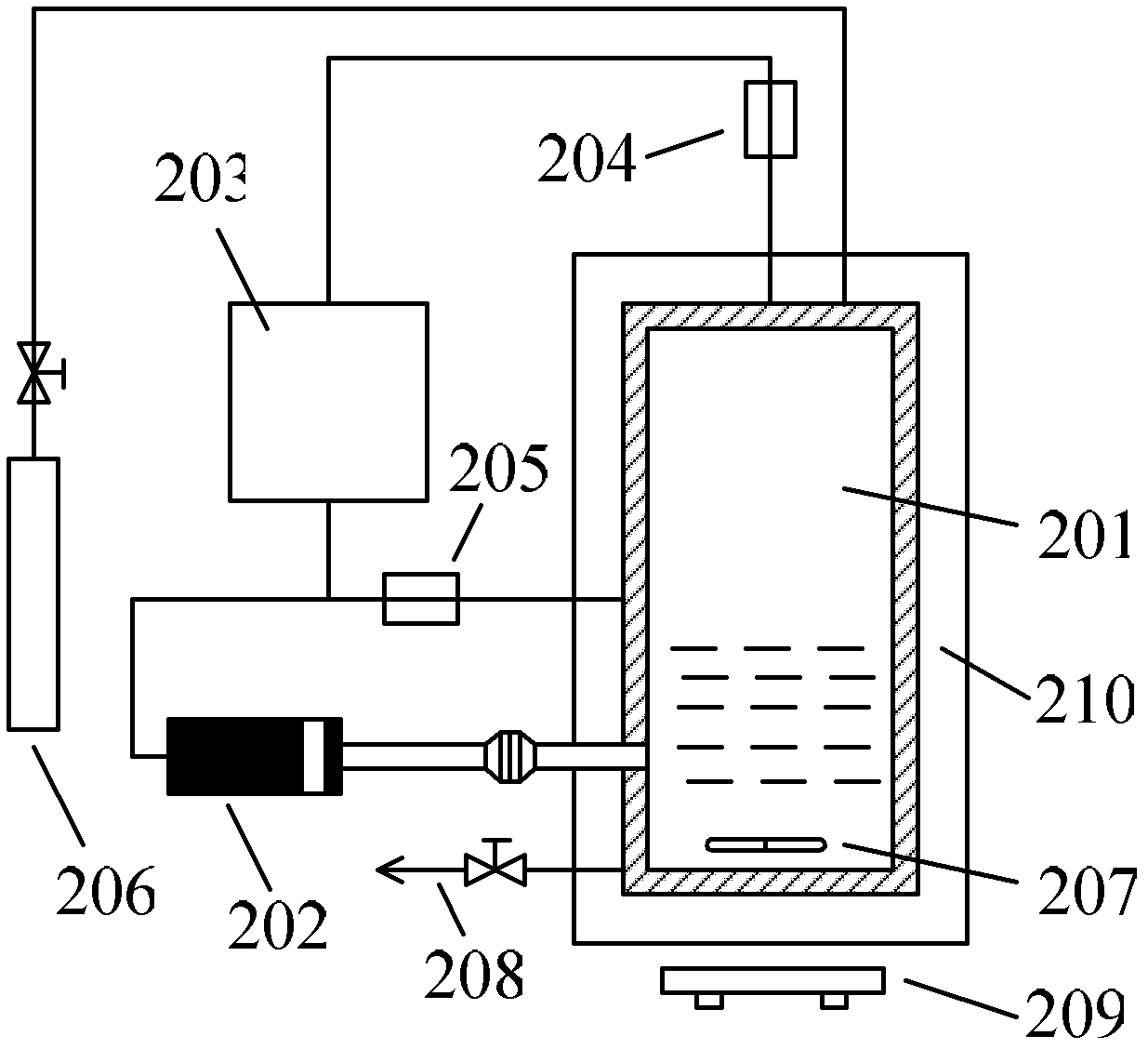

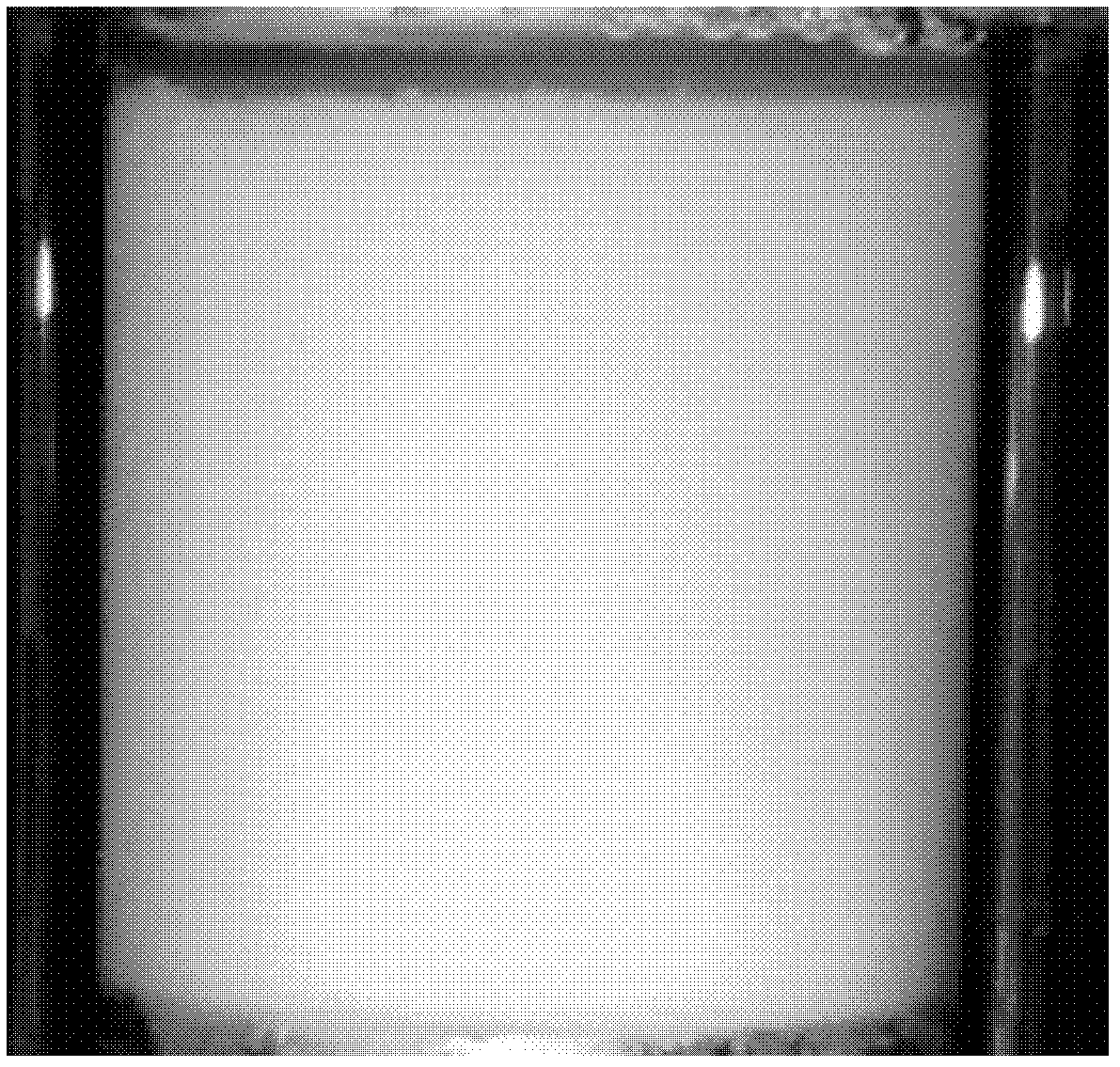

[0088] A visualized transparent sapphire autoclave and supporting system were used to test the hydrate morphology of the anti-polymerization effect of the above-mentioned saponin-containing composite hydrate anti-polymerization agent provided in this embodiment. Among them, the oil-water emulsion of the oil-gas-water mixed transportation system is prepared by 0.5mL deionized water and 9.5mL diesel oil, that is, the volume content of water in the oil-gas-water mixed transportation system is 5% (with water and The total volume of oil is calculated based on the standard), the total amount of anti-po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com