Saponin-containing composite type hydrate anti-agglomerant

A technology of anti-aggregation agent and hydrate, which is applied in the field of hydrate anti-aggregation agent and compound hydrate anti-aggregation agent. Phase and other problems, to achieve the effect of solving the problem of flow safety guarantee, uniform particle distribution, and avoiding hydrate coalescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] This embodiment provides a saponin plant extract, which is prepared through the following steps:

[0074] First select 100 g of saponin bark (the remaining skin after the saponin pod is removed from the fruit), and grind the saponin bark into powder by using a pulverizer to obtain saponin powder;

[0075] Inject the saponins powder into a Soxhlet extractor, add 600g of absolute ethanol to extract for 3 hours, and obtain a mixed solution;

[0076] The mixed solution was suction-filtered using a Buchner funnel, and the filtrate was distilled under reduced pressure using a rotary evaporator until solids were precipitated. The concentrated solution obtained at this time was a saturated solution (brown liquid), that is, a saponin plant extract.

[0077] It is determined that in the saponin plant extract extracted in this embodiment, the total saponin content is 21% of the saponin bark mass, and the saponin effective concentration in the saponin plant extract is 19%.

Embodiment 2

[0079] This embodiment provides a saponin plant extract, which is prepared through the following steps:

[0080] Select 100g of licorice and grind it into powder with a mortar to obtain licorice powder;

[0081] Pour the licorice powder into the flask, add 300g of water to leaching at 70°C for 4 hours, use a Buchner funnel to carry out suction filtration, and filter the residue again with 300g of water to leaching for 4 hours, suction filtration, repeated leaching and suction Filter four times to obtain the mixed solution, which is the sum of the liquid obtained by leaching for four times;

[0082] filtering the mixed solution, concentrating the filtrate and evaporating the water therein to dryness by vacuum distillation to obtain a solid saponin plant extract;

[0083] The above-mentioned solid is dissolved in absolute ethanol and then concentrated until solid is precipitated, and the concentrated solution at this time is the saponin plant extract.

[0084] It has been dete...

Embodiment 3

[0086] This embodiment provides a saponin-containing composite hydrate antipolymerization agent, which is prepared through the following steps:

[0087] The saponin plant extract extracted in Example 1 and the auxiliary antipolymerization agent Span20 were mixed according to a mass ratio of 3:1, and stirred evenly to obtain a composite hydrate antipolymerization agent containing saponin.

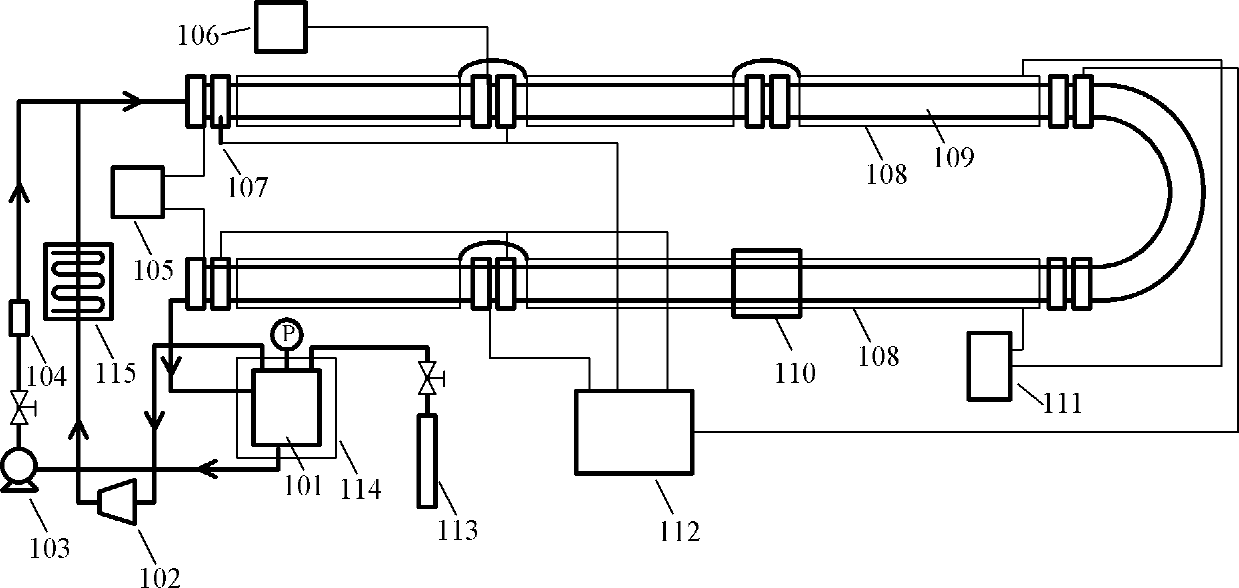

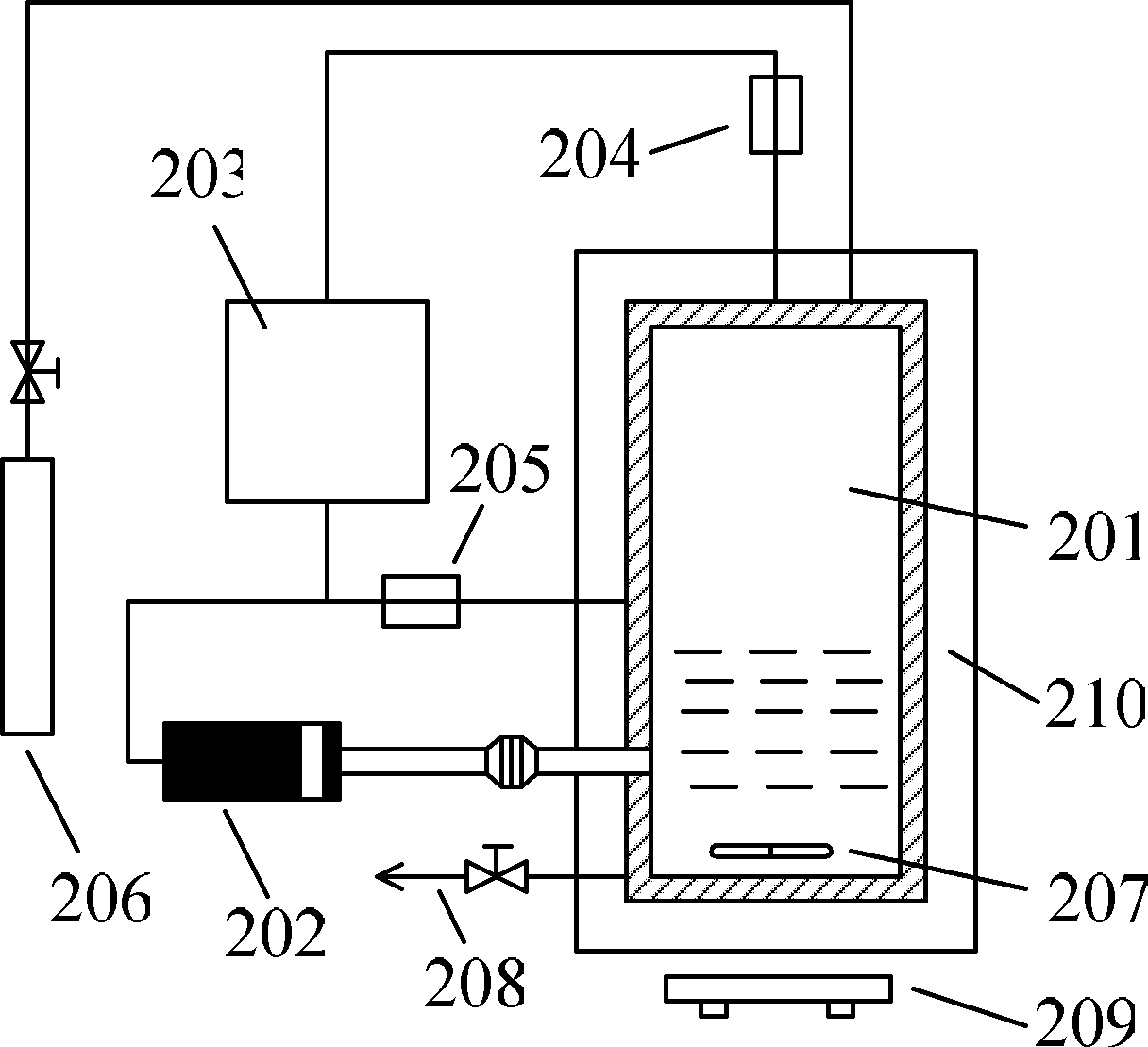

[0088] A visible transparent sapphire high-pressure reactor and supporting system were used to conduct a hydrate form test on the anti-polymerization effect of the above-mentioned saponin-containing composite hydrate anti-polymerization agent provided in this example. Among them, the oil-water emulsion of the oil-gas-water mixed transportation system is prepared from 0.5mL deionized water and 9.5mL diesel oil, that is, the volume content of water in the oil-gas-water mixed transportation system is 5% (based on water and The sum of the volumes of the oil is the basis for calculation), the tot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com