Method for deep recovery of antimony from arsenic alkali residue leaching solution by using electric potential control

A technology of potential control and arsenic-alkali slag, applied in the field of resources and environment, to avoid instant oxidation and decomposition, improve oxidation efficiency, and avoid blind addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

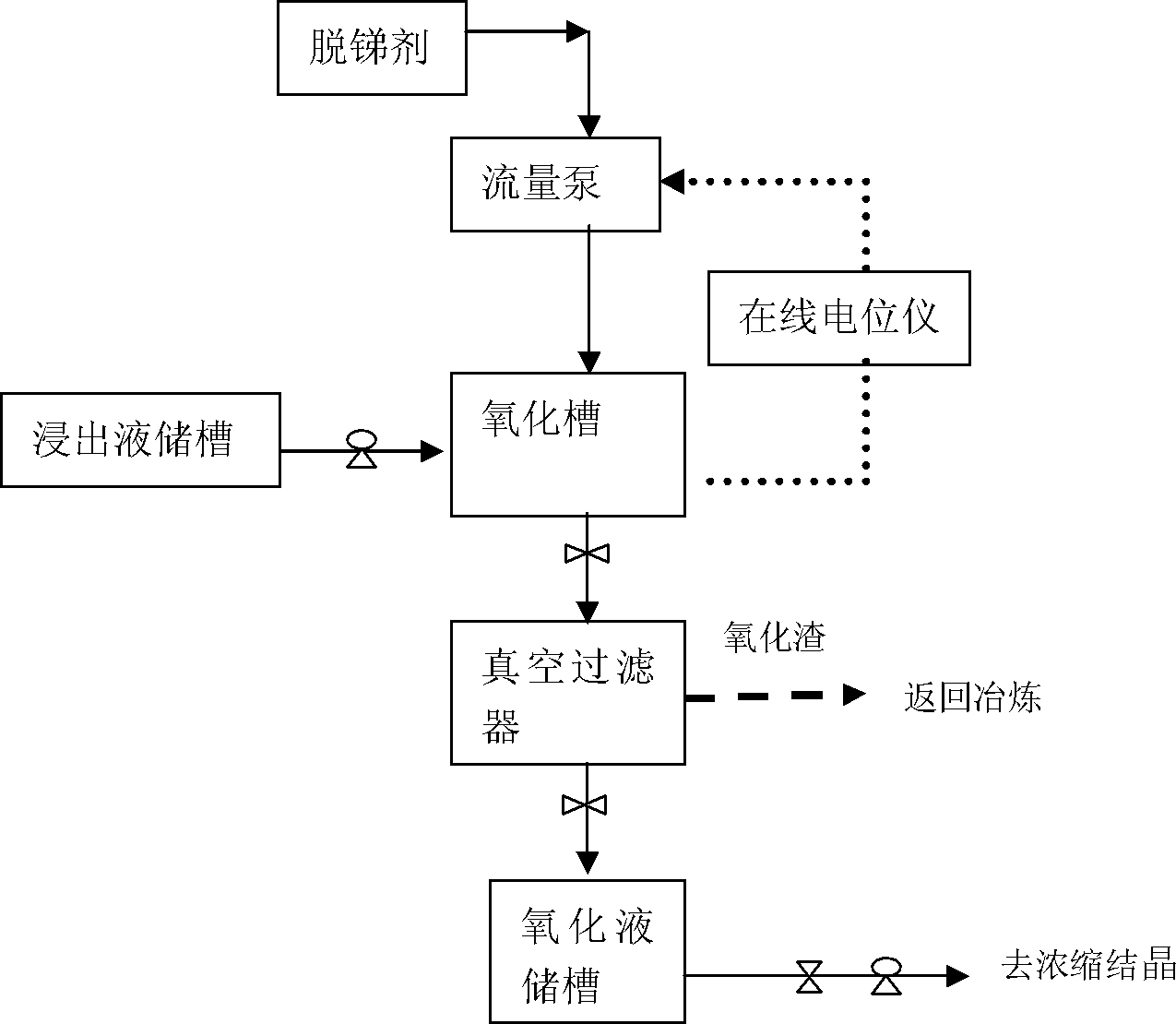

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Oxidation at room temperature, using potential control, slowly adding hydrogen peroxide at the bottom

[0032] After leaching the arsenic-alkali slag of an enterprise with hot water, 1 ton of the leach solution was taken. After component analysis, it contained Sb: 5.82g / L, As: 15.56g / L, and the temperature was 73°C.

[0033] Pump the leaching solution into the oxidation tank, add hydrogen peroxide slowly at the bottom, control the time for adding the deantimony agent to 30 minutes, and stir rapidly at the same time, the stirring speed is controlled at about 100r / min, and the stirring speed can be quickly mixed to mix the solution evenly It is advisable to quickly mix the deantimony agent with the solution. Use cooling water to cool down, keep the temperature at 25°C during the reaction process, and the total oxidation time is 60 minutes. The online electrode potentiometer is used to monitor the potential of the whole process during the reaction process. The p...

Embodiment 2

[0034] Embodiment 2: Oxidation at room temperature, one-time addition of hydrogen peroxide (comparative example)

[0035] After leaching the arsenic-alkali slag of an enterprise with hot water, 1 ton of the leachate was taken. After component analysis, it contained Sb: 5.97g / L, As: 17.69g / L, and the temperature was 79°C.

[0036] Pump the leaching solution into the oxidation tank, add 15L of hydrogen peroxide at one time, and stir rapidly at the same time, the stirring speed is controlled at 100r / min, so that the hydrogen peroxide can be mixed with the solution quickly. Cooling water was used to lower the temperature, the temperature was kept at 25°C during the reaction, and the total oxidation time was 60 minutes. After analysis, the treated leachate contains Sb: 1.26g / L, As: 16.98g / L, and the removal rate of antimony is 78.9%. The collected sodium antimonate product was 18.8kg, containing Sb: 43.16%, As: 1.12%, which reached the quality requirements of common sodium antimon...

Embodiment 3

[0037] Example 3: high temperature oxidation, take potential control, slowly add hydrogen peroxide at the bottom

[0038] After leaching arsenic-alkali slag from a certain enterprise with hot water, 1 ton of the leach solution was taken. After component analysis, it contained Sb: 5.97g / L, As: 18.20g / L, and the temperature was 75°C.

[0039] The leachate is pumped into the oxidation tank, heated by steam, and the temperature is kept at 80°C throughout the reaction process. The hydrogen peroxide is added slowly at the bottom, and the time for adding the hydrogen peroxide is controlled to be 30 minutes. At the same time, the stirring speed is controlled to be 100 r / min, so that the hydrogen peroxide is mixed with the solution quickly, and the total oxidation time is 60 minutes. During the reaction process, an online electrode potentiometer was used to monitor the potential of the whole process. During the process, the potential rose slowly. When it reached the set -620mv, the add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com