Cold-rolled steel strip for double-layer welded tube

A cold-rolled strip steel and manufacturing method technology, applied in the field of cold-rolled strip steel, can solve the problems of poor yield and performance uniformity, and achieve the effects of high-speed continuous production, high yield, and good roll forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

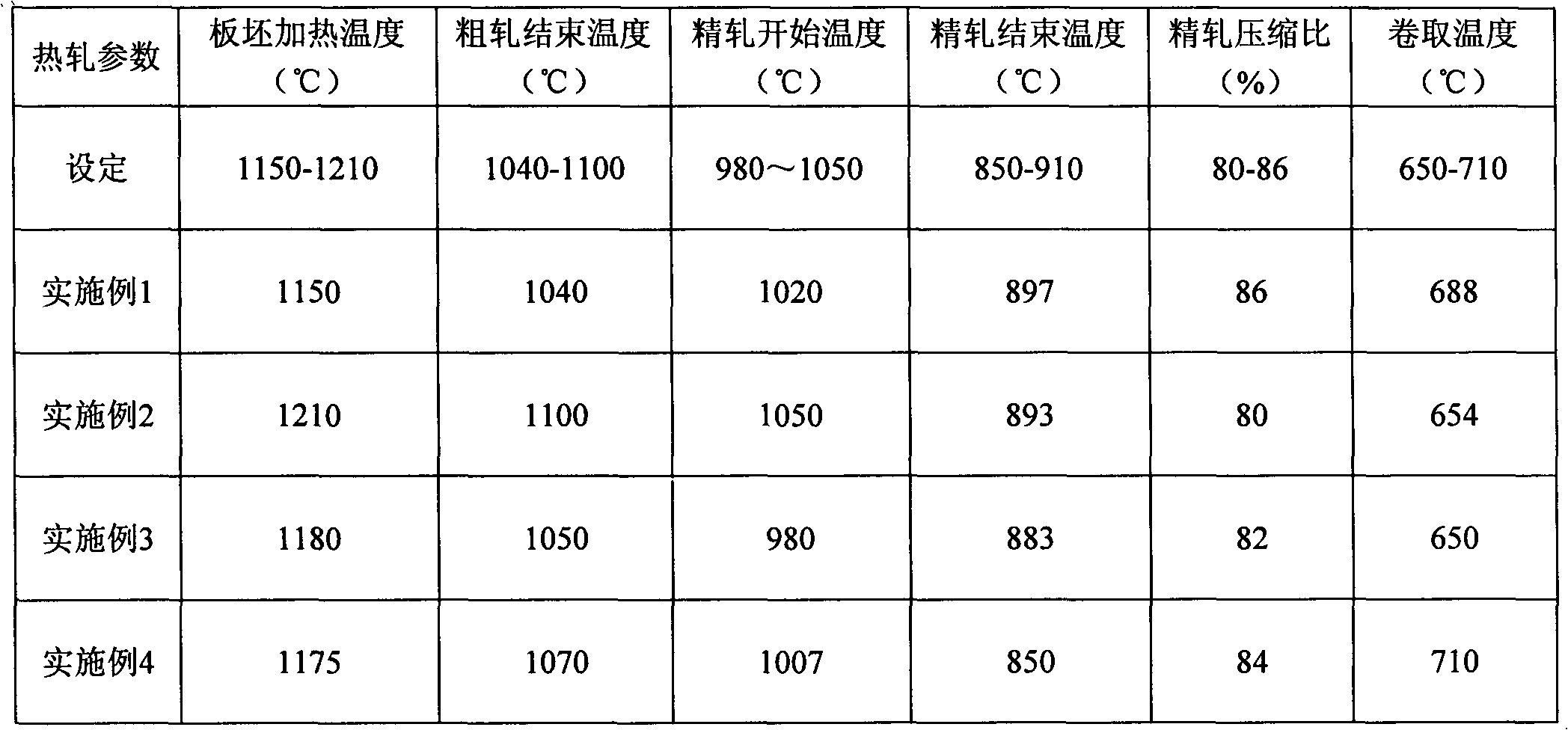

Embodiment 1-4

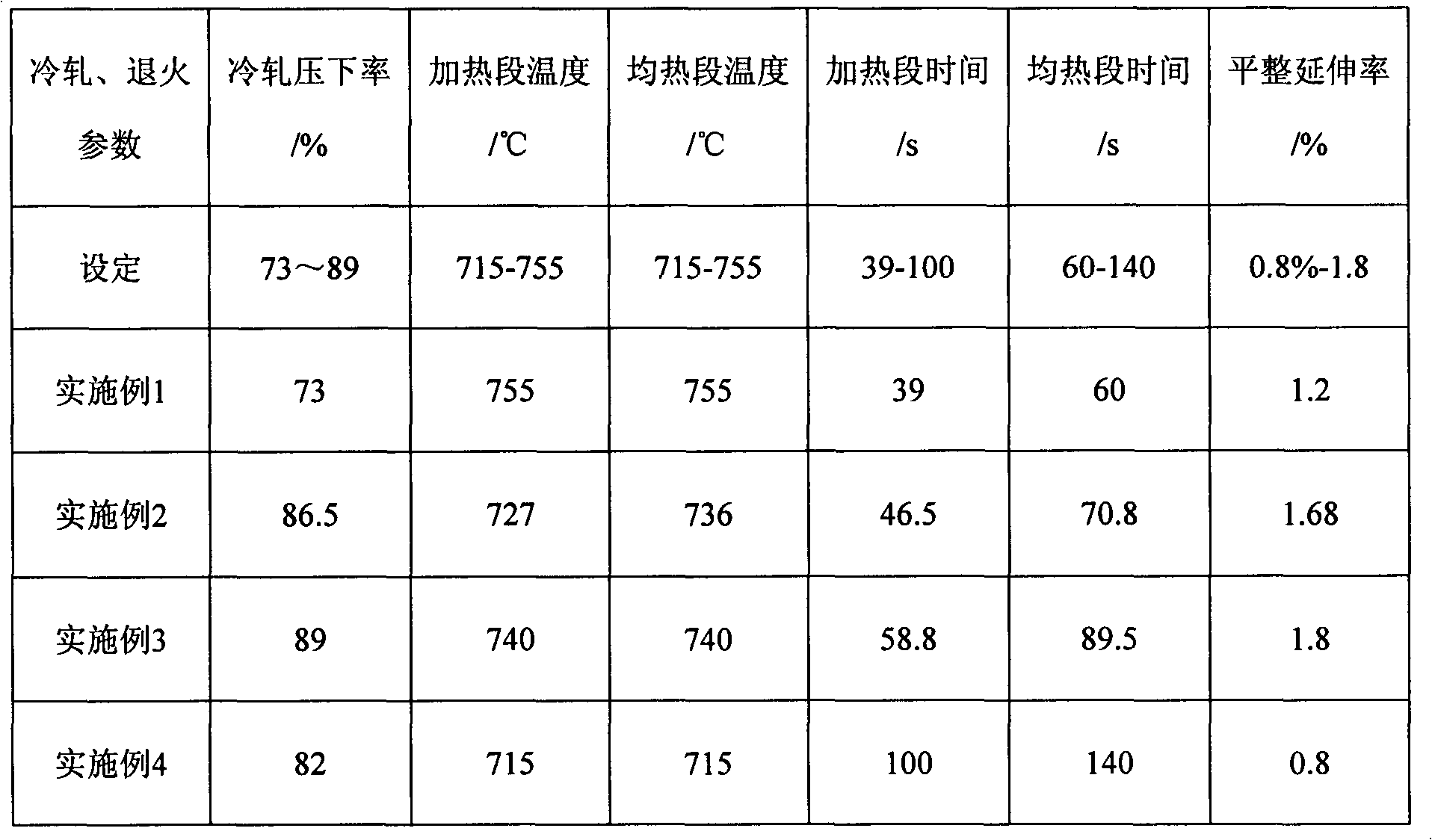

[0042] Table 3 Embodiment 1-4 cold rolling and annealing process control parameters of the present invention

[0043]

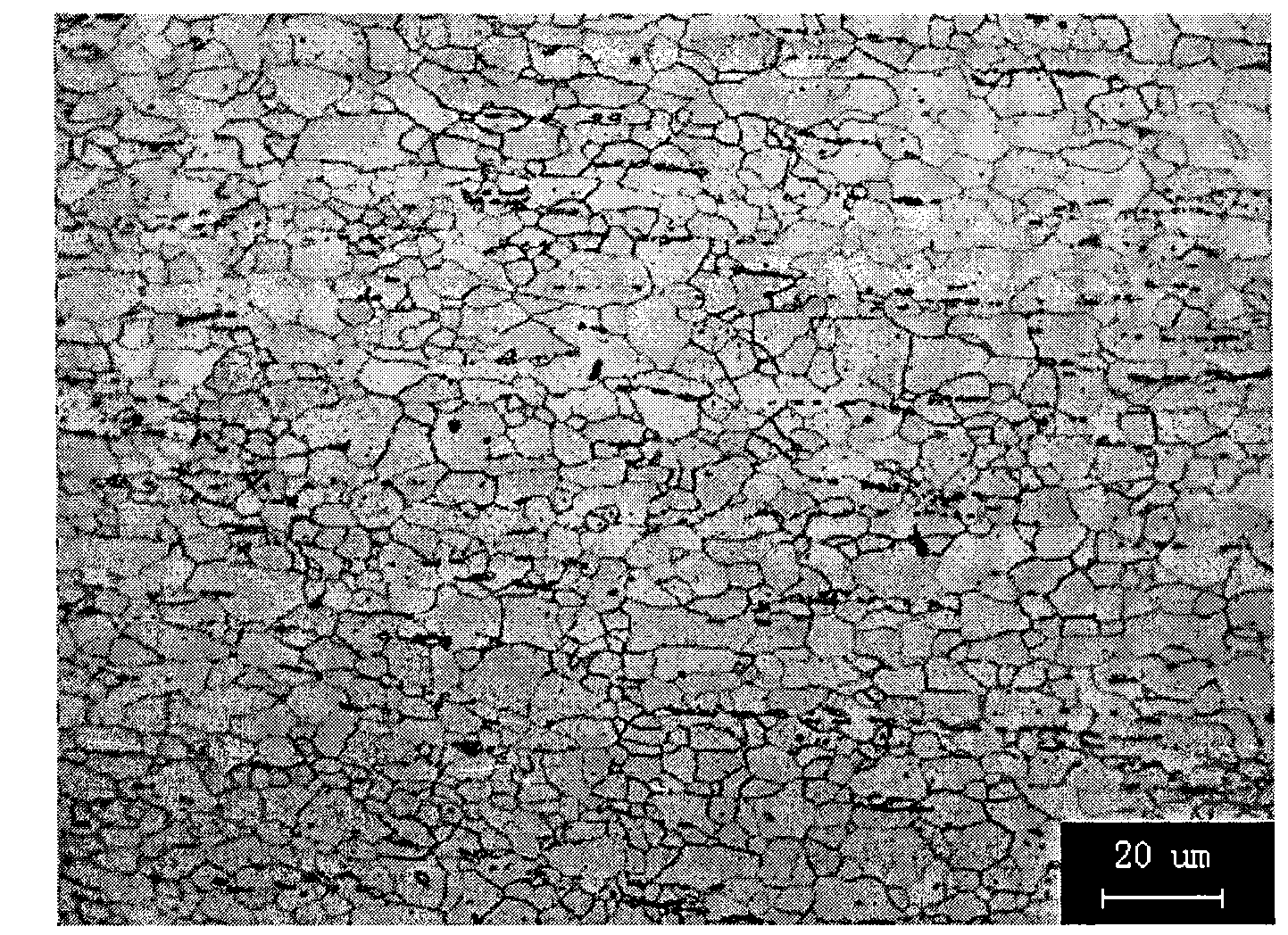

[0044] The mechanical properties of the cold-rolled steel strip for double-layer coiled welded pipe obtained by the above method are: yield strength Rel is 170-260 MPa, hardness HR30T is 40-52, elongation after fracture is ≥ 32%, and the microstructure grain size level is I8.0~I8.5 grade, metallographic structure reference figure 1 , sampling test mechanical properties and micro-grain size rating are shown in Table 4.

[0045] Table 4 Mechanical properties of cold rolled samples

[0046] Performance

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com