Application of assistant agent in electronic-grade glass fiber cloth desizing and desizing process thereof

A glass fiber cloth and electronic grade technology, which is applied in the field of desizing process of electronic grade glass fiber cloth, can solve the problems of increasing desizing temperature, abnormal cloth breakage and high desizing temperature, so as to ensure tensile strength and improve wettability. , the effect of reducing ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example One: Selection of Chemical Auxiliaries

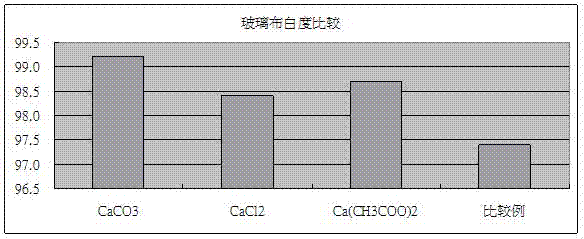

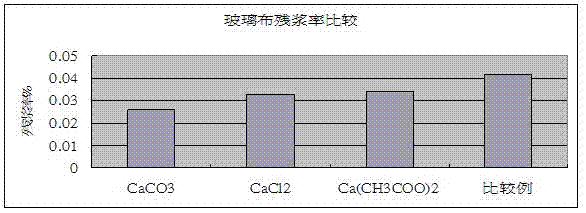

[0031] Three types of chemical additives are selected to be applied to the cloth surface in the form of aqueous solution, and the desizing properties are compared through the same desizing method, and the chromaticity, tensile strength and organic matter content on the cloth surface are compared and analyzed:

[0032] Table 1 Ca 2+ Compound solution formula and data comparison analysis table (each component by mass percentage)

[0033]

[0034] Table 1 uses 1506, 2116, 1080, 106, 101 series desizing cloth (thickness is 0.16-0.025mm) produced by Shanghai Honghe Electronic Materials Co., Ltd., the test results are as follows figure 1 , figure 2 As shown, the data are recorded in Table 1, and the above graph shows that at a concentration of 0.3% CaCO 3 Compound works best as a desizing aid.

[0035]

Embodiment 2

[0036] Embodiment two: proportioning concentration type selection

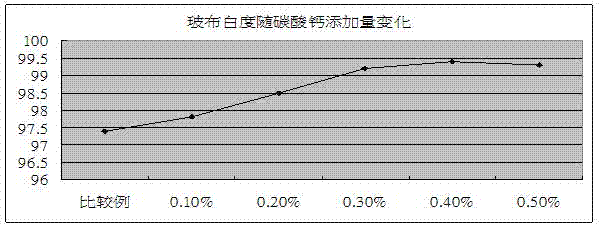

[0037] Formulated CaCO 3 Different proportions of aqueous solution, the same desized cloth sample is immersed in different proportions of the solution, taken out and dried, put into the intermittent secondary desizing furnace for high-temperature desizing, after taking it out, compare the chromaticity value (L value) and Organic matter content, determine the solution concentration with the highest L value and the lowest organic matter content, and the tensile strength does not fluctuate significantly after repeated tests, and the stability is determined through repeated operations.

[0038] refer to image 3 , Figure 4 The curves shown are consolidated into Table 2 below.

[0039]

[0040]Table 2 still uses 1506, 2116, 1080, 106, 101 series desizing cloth (thickness 0.16-0.025mm) produced by Shanghai Honghe Electronic Materials Co., Ltd., the test results show that CaCO 3 The solution with a concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com