Speed adjustable electromagnetic fan clutch structure with independent controller

An electromagnetic fan and clutch technology, applied in the direction of magnetic drive clutch, clutch, non-mechanical drive clutch, etc., can solve the problems of engine water temperature fluctuation, engine power waste, excessive heat dissipation capacity, etc., to reduce power loss, meet mass production, Easy to place effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Further description will be made below in conjunction with the accompanying drawings and the reduction of diesel engine power loss described in the present invention.

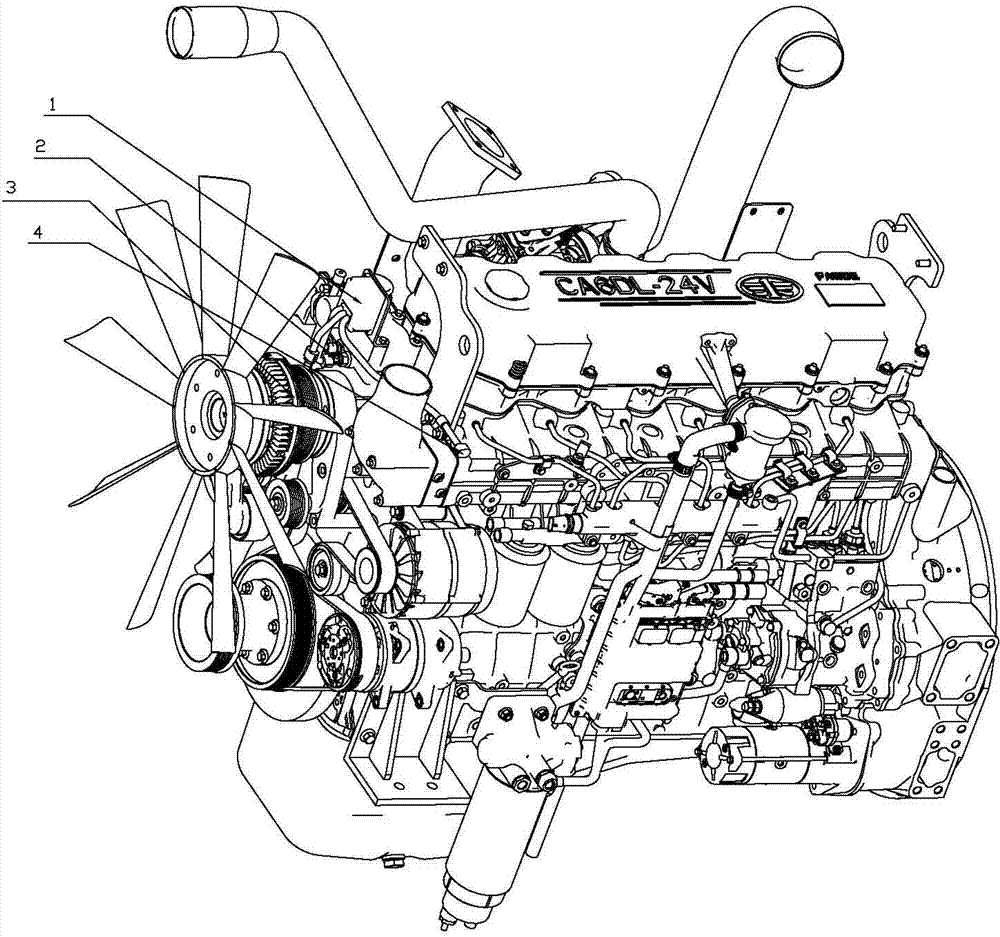

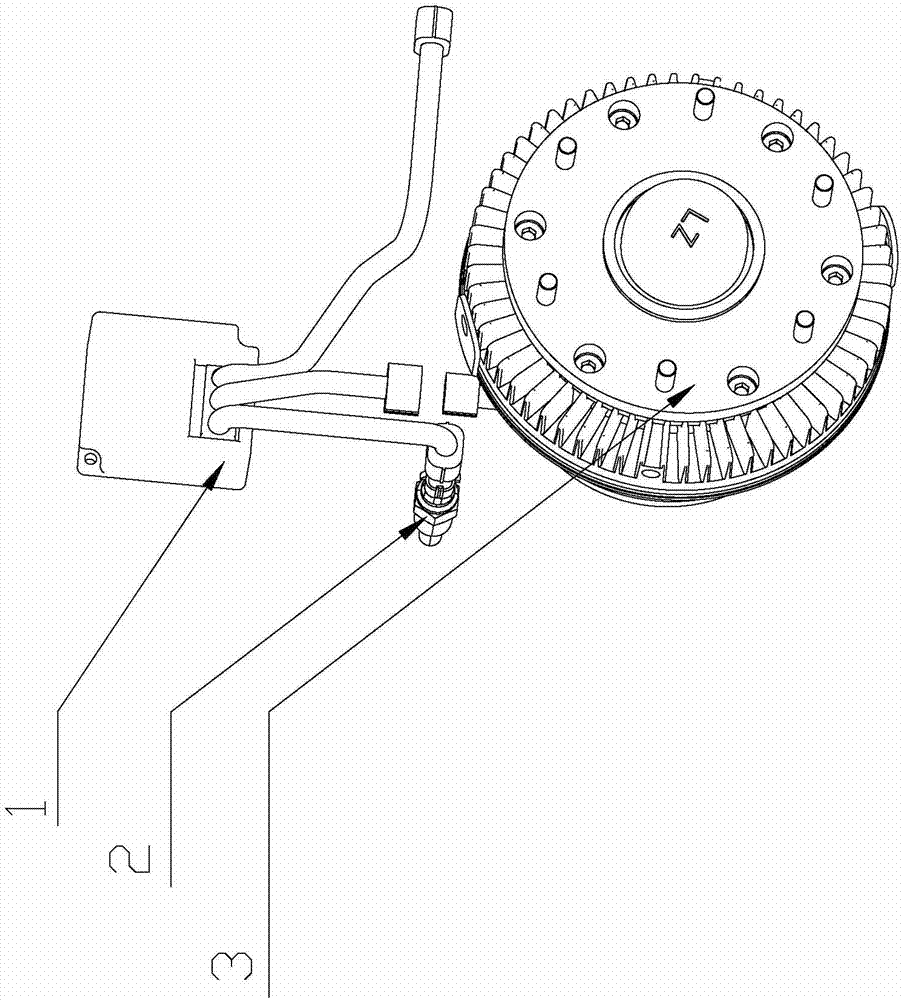

[0014] Such as Figure 1 ~ Figure 2 As shown, it includes a controller 1 with a microprocessor, a water temperature sensor 2, an electromagnetic fan clutch 3, and a vehicle connector 4.

[0015] The output end of the controller 1 with a microprocessor is connected to an electromagnetic fan clutch 3 , the temperature sensor 2 is connected to the controller 1 with a microprocessor, and the electromagnetic fan clutch 3 is connected to a vehicle connector 4 . The control loop is separated from the execution loop, the large current of the actuator will not affect the control loop, and the water temperature of the engine can be controlled at the optimum temperature.

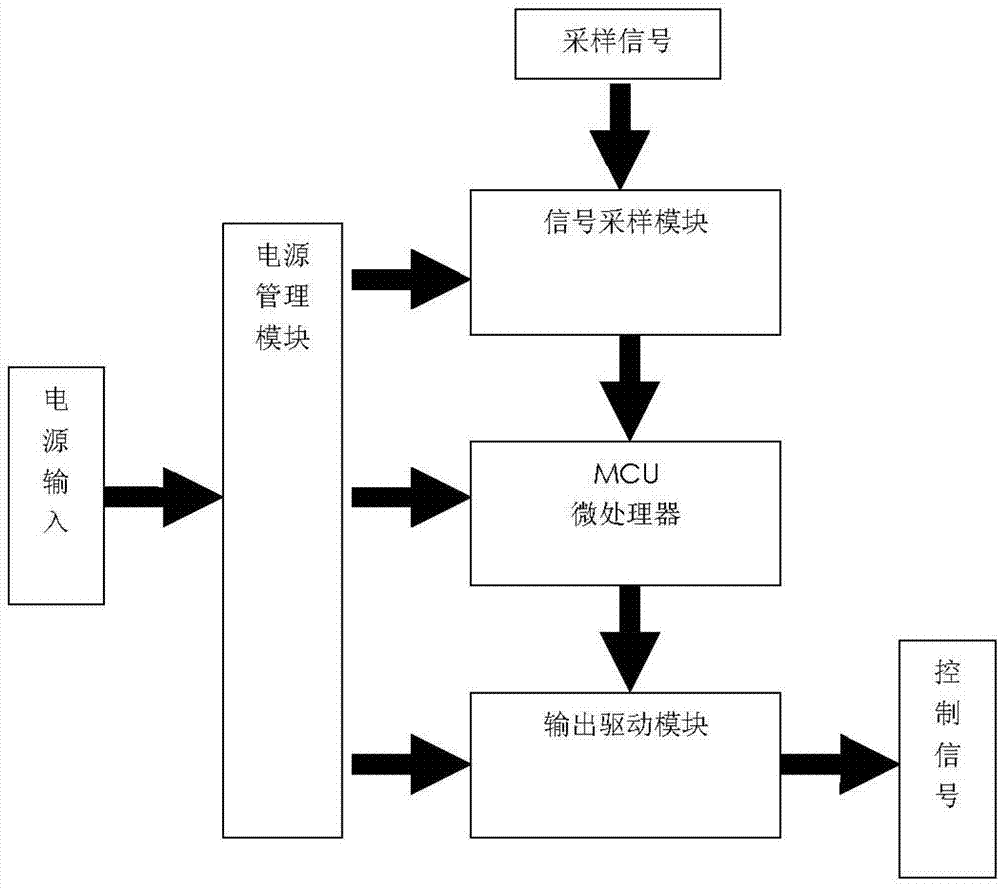

[0016] Such as image 3 As shown, the controller with a microprocessor includes a power management module, a signal sampling module, an MCU mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com