Optical diffusion barrier and preparation method thereof, and liquid crystal display device

A technology of optical diffusion and particle diffusion, applied in optics, nonlinear optics, instruments, etc., to achieve the effects of simple process, easy operation, good diffusivity and brightness enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

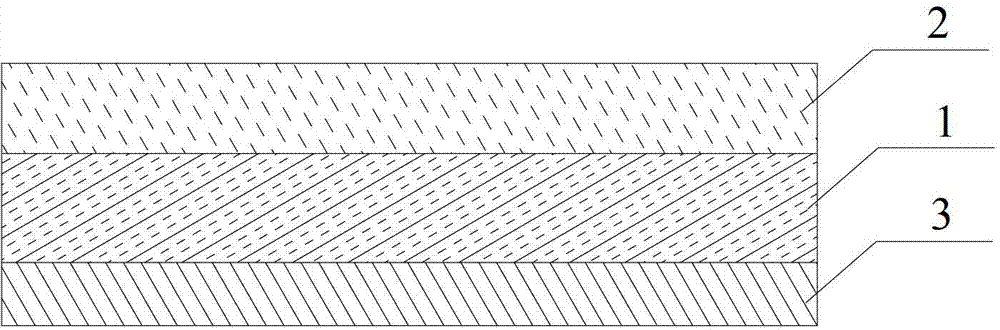

[0053] The present invention also provides a preparation method of the above-mentioned optical diffusion film, comprising the following steps:

[0054] (1) The upper diffusion particles and adhesive used in the upper diffusion coating are formulated into the upper diffusion glue coating, and an appropriate amount of solvent can be added to adjust the viscosity of the glue coating to facilitate the coating process. In a dust-free environment, corona treatment is carried out on the surface of the transparent substrate, and the upper diffusion glue coating prepared by mixing is coated on the corona surface of the above substrate;

[0055] (2) Transfer the coated substrate obtained in step (1) to dry in a gradient oven, the oven temperature is 80°C-125°C, and wind up;

[0056] (3) Send the rolled film obtained in step (2) into the drying room for curing for 48 hours, and the curing temperature is 50-60°C;

[0057] (4) The lower diffusion particles and adhesive used in the lower d...

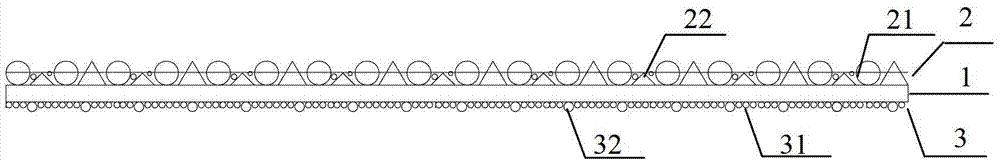

Embodiment 1

[0067] The optical diffusion film is prepared according to the above method, wherein, the upper diffusion particles are polymethyl methacrylate, the weight accounts for 50% of the upper diffusion coating, and its shape is spherical or triangular pyramid, and the particle size of the spherical upper diffusion particles is The diameter is 10-20um, the particle diameter of the circumscribed circle of the diffusion particles on the triangular pyramid is 12um, and the refractive index of the diffusion particles is 1.49; 0.5% of the upper diffusion particle, its shape is spherical or ellipsoid, the particle diameter of the lower diffusion particle of the sphere is 8-10um, the long diameter of the lower diffusion particle of the ellipsoid is 8um, and the short diameter is 5um. The refractive index of the diffusing particles is 1.39. The properties of the obtained optical diffusion film are listed in Table 1.

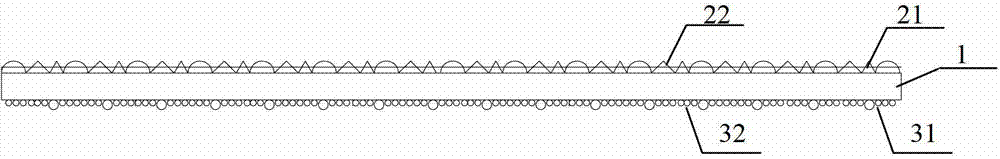

Embodiment 2

[0069] Prepare the optical diffusion film according to the above method, wherein, the upper diffusion particle is a combination of polymethyl methacrylate and polyethylene, the weight is 80% of the upper diffusion coating, and its shape is hemispherical or triangular pyramid. The particle diameter of the diffused particles on the hemispherical shape is 20-30um, the particle diameter of the circumscribed circle of the diffused particles on the triangular pyramid is 15um, and the refractive index of the diffused particles on the described upper is 1.59 and 1.74; Styrene, weight is 20% of upper diffusion particle, and its shape is spherical or triangular pyramid, and the particle diameter of described spherical lower diffusion particle is 10um, and the particle diameter of the circumscribed circle of described triangular pyramid lower diffusion particle is 12um, The refractive index of the lower diffusing particles is 1.49; the properties of the obtained optical diffusing film are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com