Application method of titanium magnesium phosphate in anode material of chargeable magnesium battery

A technology of titanium magnesium phosphate and positive electrode materials, applied in the direction of battery electrodes, circuits, electrical components, etc., to achieve the effects of high discharge voltage, good rate performance, and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

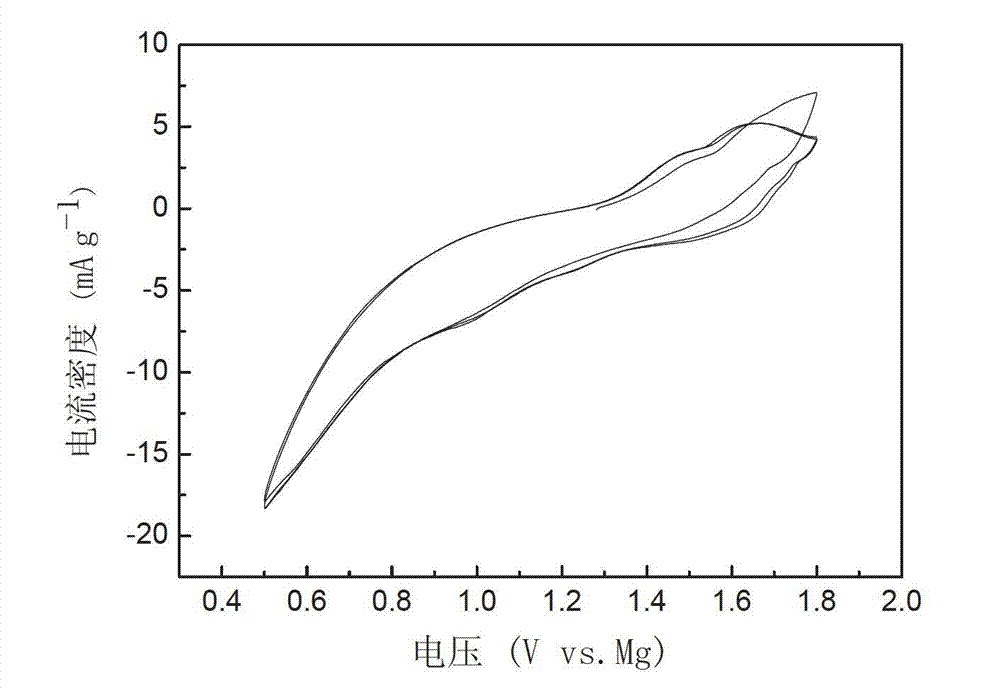

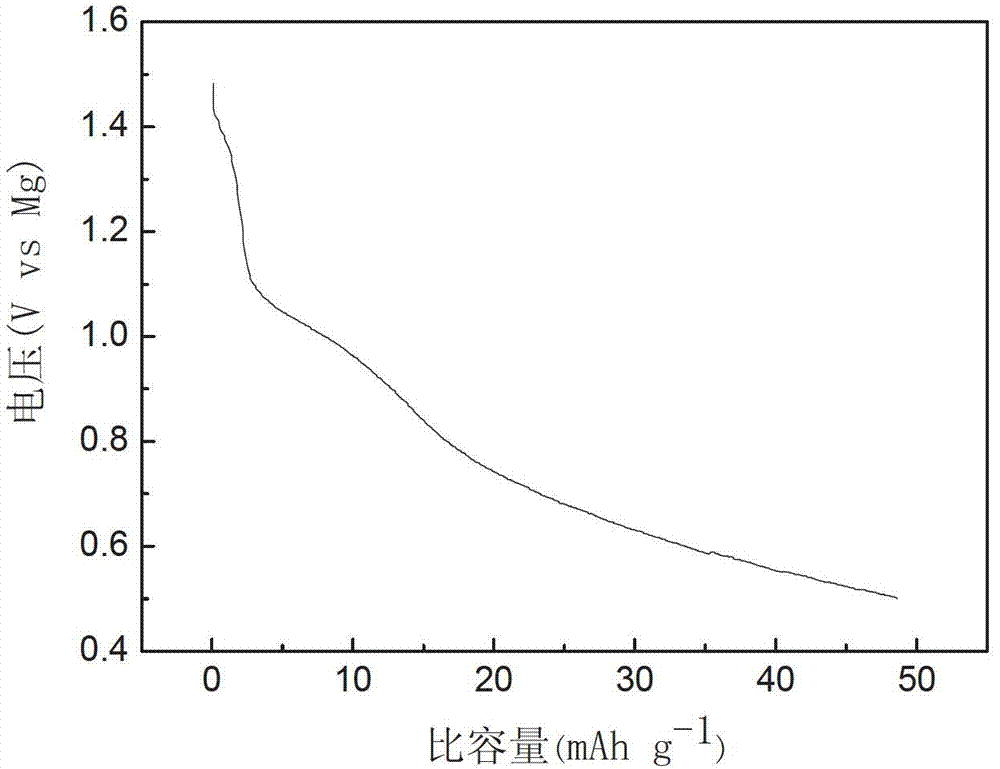

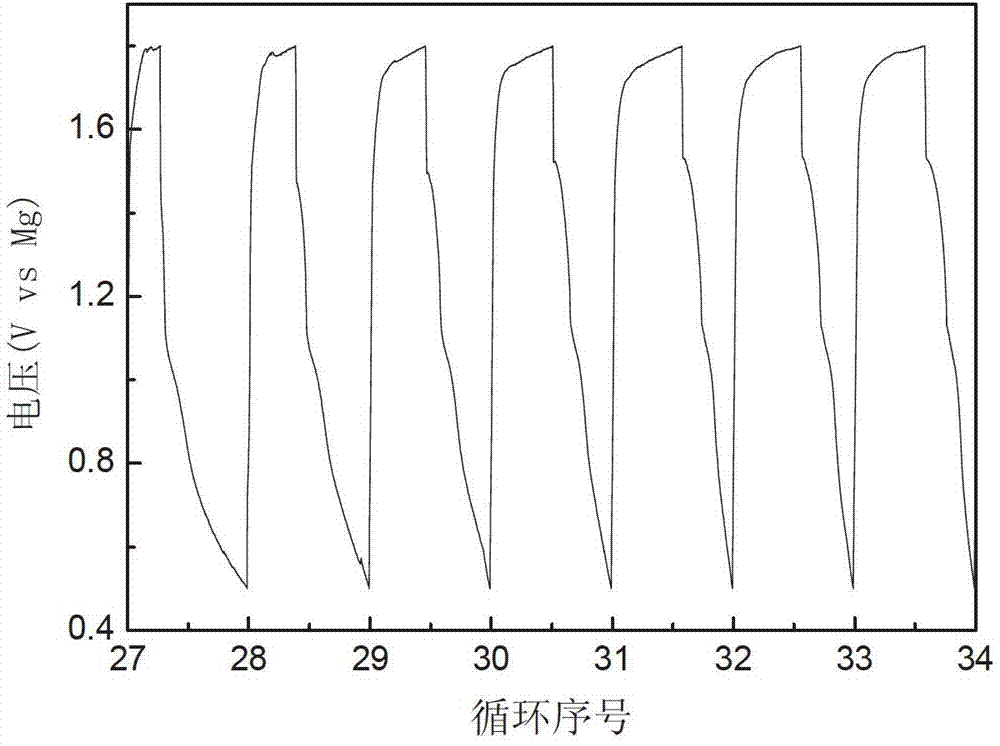

[0023] Grind titanium magnesium phosphate finely, add 1 part of super conductive carbon black as conductive agent and 1 part of binder to 8 parts of titanium magnesium phosphate, stir evenly, coat on copper foil, and put it in an oven at 80°C After drying, punch a pole piece with a punch with a diameter of 12mm, press it under a pressure of 1MPa, and dry it in a vacuum oven at 100°C for 4 hours to obtain a positive electrode, which is then transferred to an argon glove box and sealed with metal. Magnesium is the negative electrode, 0.25mol L -1 Mg(AlCl 2 BuEt) 2 / THF solution is used as the electrolyte, which is assembled into a rechargeable magnesium battery. Its cyclic voltammetry curve is as figure 1 As shown, the scanning speed is 0.5mV·s -1 . Depend on figure 1 It can be seen that titanium magnesium phosphate has electrochemical activity. figure 2 The charging test results of its 27th lap, by figure 2 As shown, the charge and discharge current density in the te...

Embodiment 2

[0025] Grind titanium magnesium phosphate finely, add 1 part of super conductive carbon black as conductive agent and 1 part of binder to 8 parts of titanium magnesium phosphate, stir evenly, coat on copper foil, and put it in an oven at 80°C After drying, punch a pole piece with a punch with a diameter of 12 mm, press it under a pressure of 1 MPa, and dry it in a vacuum oven at 100 ° C for 4 hours to obtain a positive electrode, which is then transferred to an argon glove box and sealed with metal. Magnesium is the negative electrode, add 0.4mol L -1 (PhMgCl) 2 -AlCl 3 / tetrahydrofuran solution electrolyte, assembled into a rechargeable magnesium battery. Figure 5 is the current density of 1.20mA·g -1 , the discharge data of the first cycle of titanium magnesium phosphate; Figure 5 It can be seen that there is a discharge platform around 1V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Discharge current density | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com