A servo electric cylinder

A servo electric cylinder and servo motor technology, applied in the field of servo electric cylinders, can solve the problems of low transmission accuracy, pollute the site environment, and limited bearing capacity, and achieve the effects of high transmission accuracy, improved connection strength, and large bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

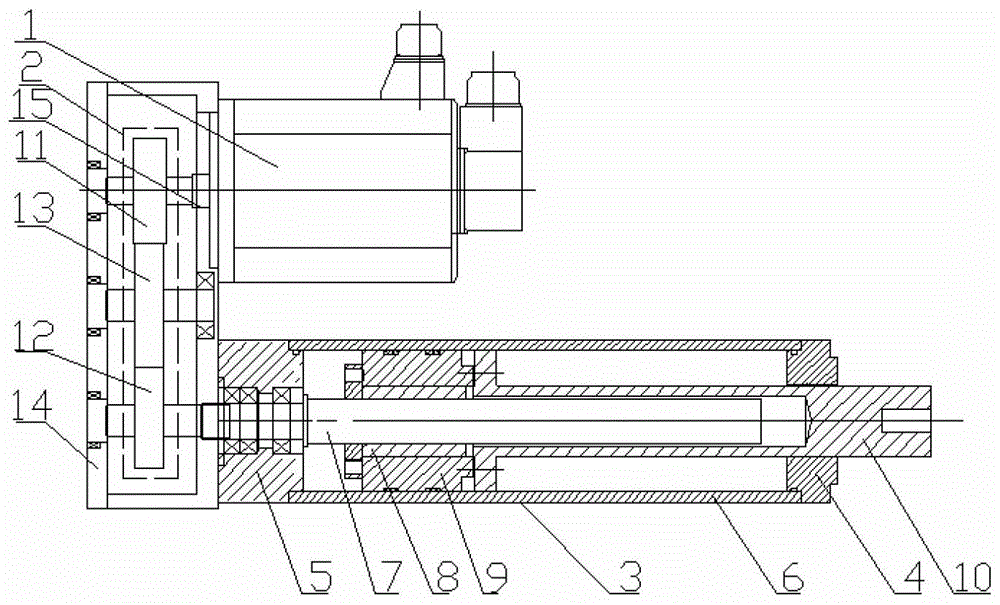

[0018] figure 1 A servo electric cylinder shown includes a servo motor 1, a transmission mechanism 2, a cylinder structure 3, a front end plate 4, a rear end plate 5, a cylinder body 6, a screw rod 7, a movable nut 8, a nut seat 9, and a push rod 10 , Driving wheel 11, driven wheel 12, idler wheel 13, cover 14 and sealing ring 15.

[0019] figure 1 A servo electric cylinder shown mainly includes a servo motor 1 , a transmission mechanism 2 and a cylinder structure 3 . The cylinder structure 3 is composed of a front end plate 4, a rear end plate 5 and a cylinder 6 placed between them, and a screw 7 and a movable nut 8 are arranged at the central axis of the cylinder structure 3, and the movable nut 8 is sleeved on the screw 7 is placed on the nut seat 9, and a guiding structure is arranged between the nut seat 9 and the inner wall of the cylinder body 6 along the axial direction of the screw rod 7. One end of the screw rod 7 is placed in the rear end plate 5 through a bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com