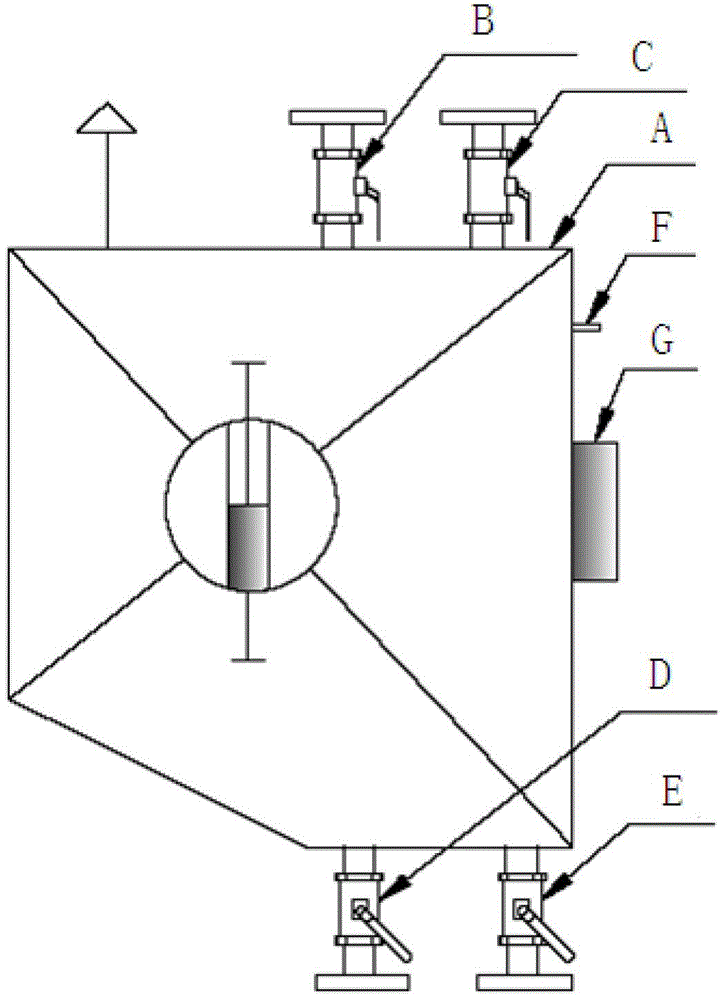

Urea solution online preparation device for SCR (Selective Catalytic Reduction) systems of marine diesel engines

A technology of SCR system and marine diesel engine, applied in the field of urea preparation device of marine diesel engine SCR system, can solve the problems of reducing the effective load of ships, space shortage, large exhaust flow, etc., to reduce the difficulty of urea storage, save space, and facilitate replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

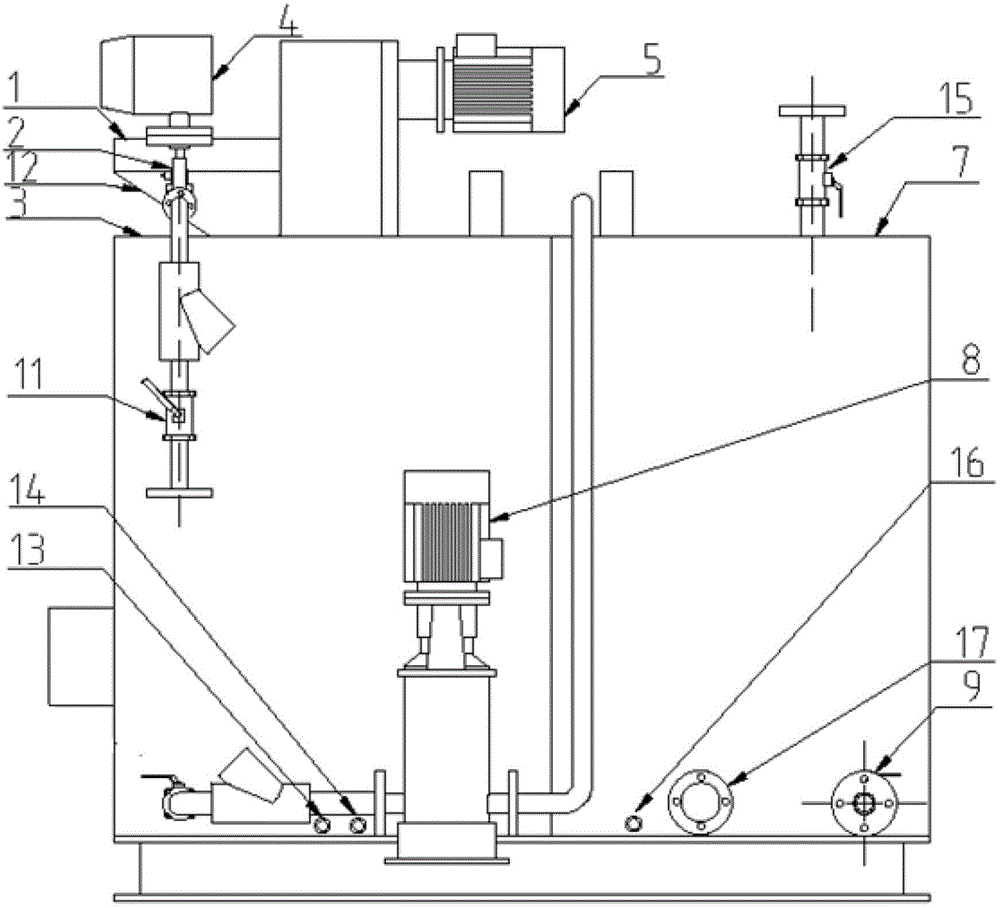

[0019] See attached figure 2 , a marine diesel engine SCR system urea online preparation device, which includes: urea dry powder dispenser 1, solenoid valve 2, urea solution mixing chamber 3, electromagnetic flowmeter 4, electric stirrer 5, liquid level sensor, urea solution storage chamber 7 , Stirring chamber transfer pump 8, filter, manual ball valve 11, weighing sensor 12, urea concentration sensor 13, temperature sensor A14, temperature sensor B16 and control system;

[0020] There is urea dry powder stored in the urea dry powder dispenser 1, and the urea dry powder dispenser 1 is connected to the urea solution mixing chamber 3 through the load cell 12; if paired with 10L of urea aqueous solution with a concentration of 40%, add 4000g of urea dry powder and 6L of Deionized water;

[0021] The urea solution stirring chamber 3 is the preparation chamber of the urea solution, and an electric stirrer 5 is installed on the top thereof, and a pipeline for providing deionized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com