Honeycomb-type organic solid waste fermentation system

An organic solid and fermentation system technology, applied in the direction of solid waste removal, etc., can solve the problems of low land utilization, high fermentation cost, and high equipment input cost, and achieve improved ventilation performance, high land utilization, and improved fermentation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

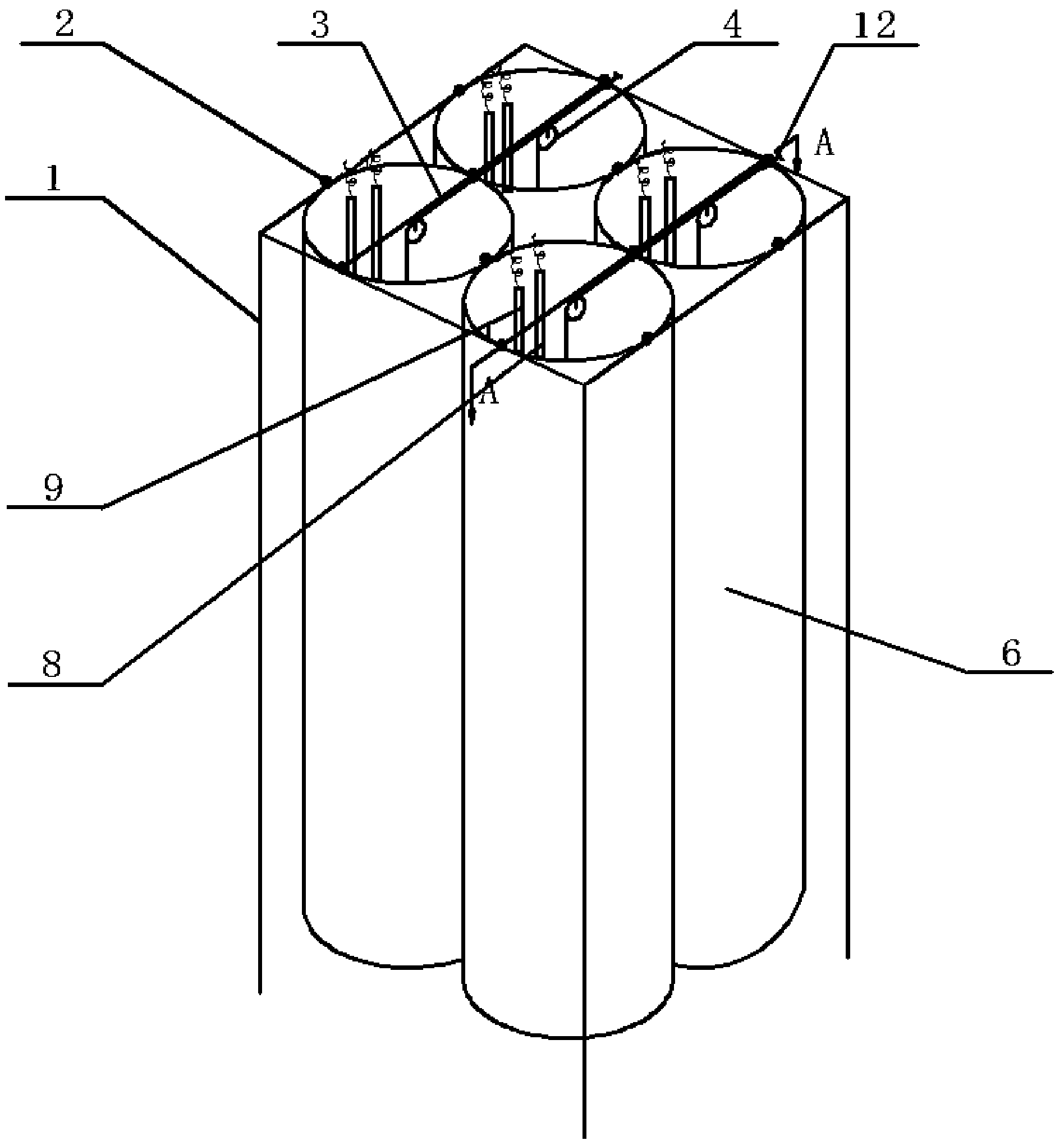

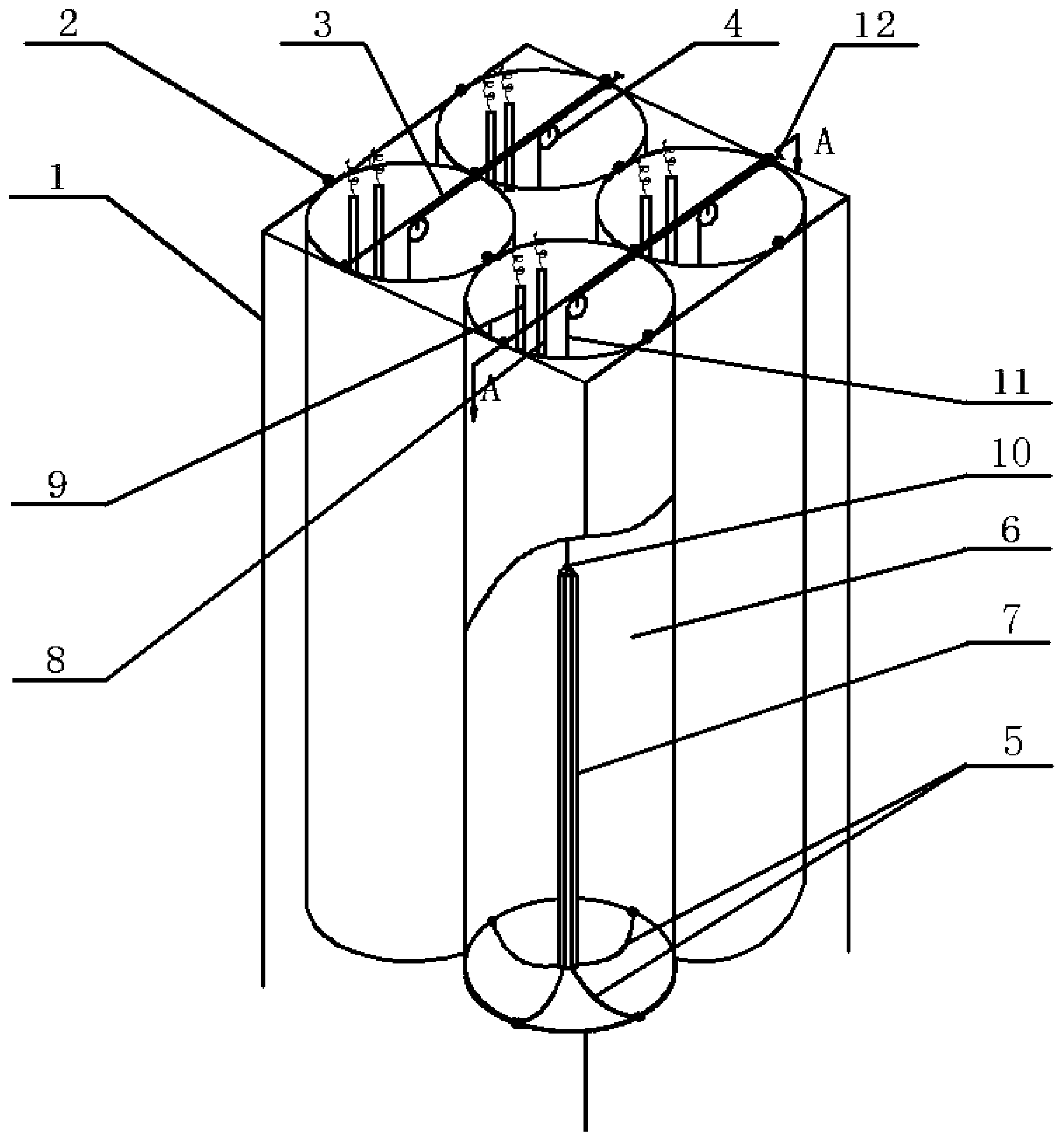

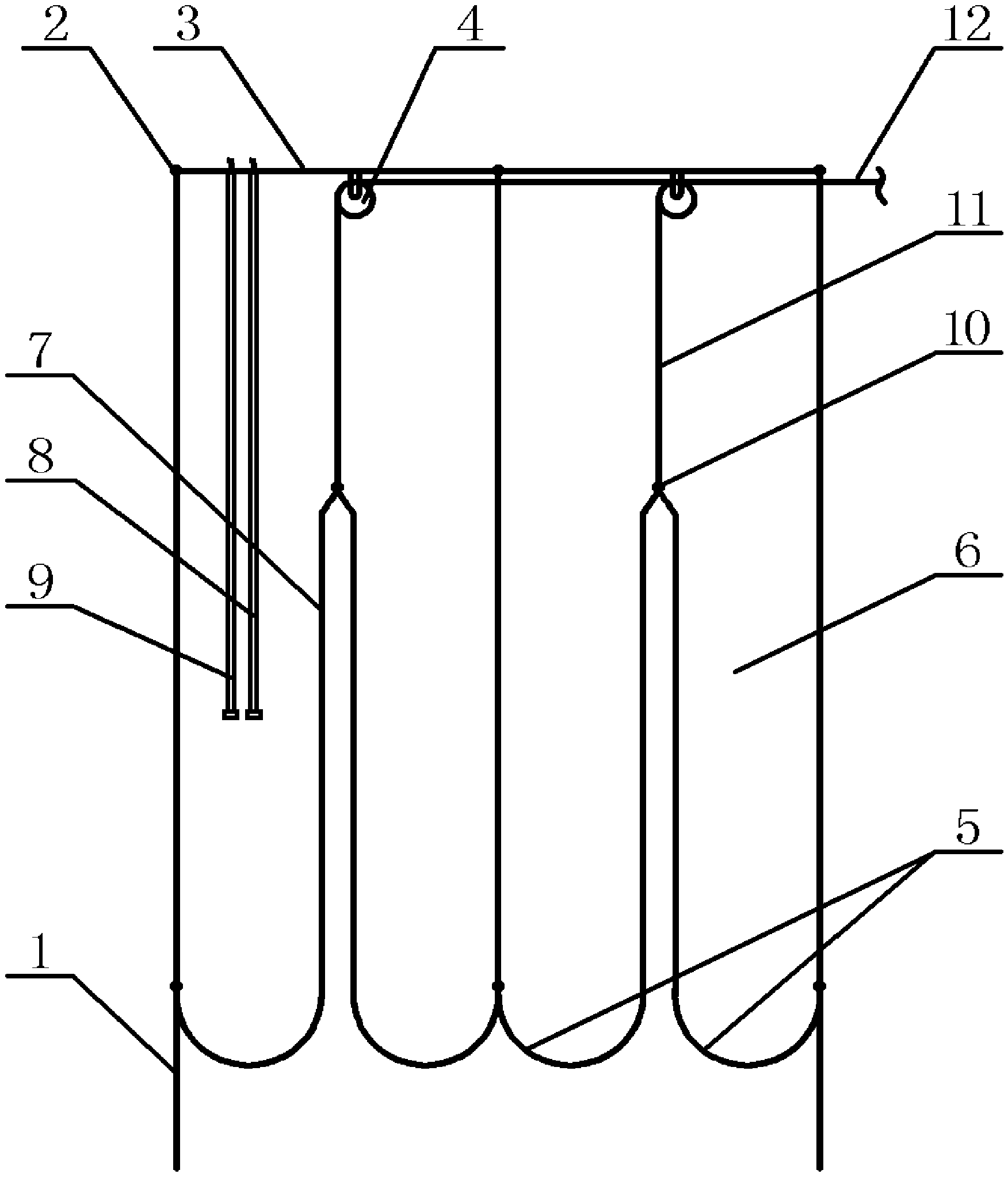

[0049] Such as Figure 1~Figure 3 As shown, a cellular organic solid waste fermentation system is composed of four fermentation units tangentially arranged and combined. The fermentation unit includes a load-bearing device 1, a fermentation device and a detection device. The detection device is located in the fermentation device. The load-bearing device 1 Fixing device I2 and fixing device II3 are provided on the top; the opening of the fermentation bag 6 is connected to the fixing device I2, and the inner center of the fermentation bag 6 is provided with a traction belt 5, a central axis tube 7 and a steering device 4, and one end of the traction belt 5 is connected to the fermentation bag 6 The outer surface is connected, and the other end extends from the bottom end of the central axis tube 7 to the confluence point 10 at the top of the central axis tube 7 and is connected to the external power, and the part of the traction belt 5 from the bottom end of the central axis tube...

Embodiment 2

[0052] The difference from Embodiment 1 is that: a steering device 4 is provided above the central axis tube 7, and the steering device 4 is connected to the fixing device II3; 10. Connect with the external power 12 after steering by the steering device 4; the steering device 4 is a pulley.

[0053]

Embodiment 3

[0055] The difference from Embodiment 2 is that: a stay rope 11 is provided between the confluence of the top of the central axis tube 7 and the steering device 4 , and the stay rope 11 is connected to an external power 12 after being steered by the steering device 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com