Dry outdoor type electric power complete equipment insulation casting material and preparation method thereof

A complete set of equipment and castable technology, used in insulators, circuits, electrical components, etc., can solve the problems of brittleness and poor weather resistance of epoxy insulation materials, and achieve good outdoor weather resistance, simple process, high insulation and mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

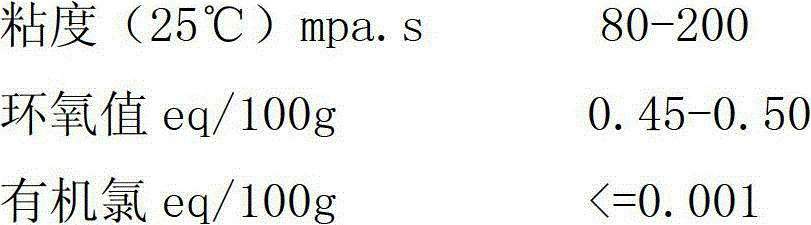

[0024] 1. Insulation castables for dry-type outdoor electric complete sets of equipment are composed of the following raw materials:

[0025] EHL-55A Modified High Purity Flexible Cycloaliphatic Epoxy Resin

100 parts (weight ratio)

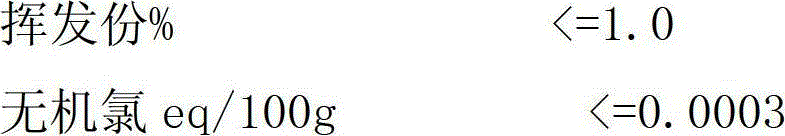

EHLS-60 modified methyl hexahydrophthalic anhydride

80 copies

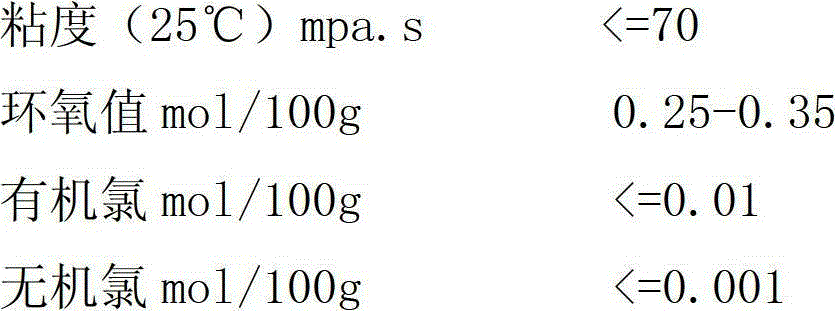

EHLP-200 reactive toughening agent

17 copies

[0026] N,N benzyldimethylamine accelerator

0.2 parts

EHLA-400 coupled silica powder

300 copies

LA epoxy stain

1 copy

[0027] 2. The preparation method of the insulating castable for dry-type outdoor electric complete sets of the present invention is as follows:

[0028] a. First, weigh each raw material according to the above weight components, preheat EHL-55A modified high-purity flexible cycloaliphatic epoxy resin at 90°C for 1.5 hours, add EHLA-400 coupled silica powder, EHLP-200 Reactive toughening agent, EHLS-60 modified methyl hexahydrophthalic anhydri...

Embodiment 2

[0035] 1. Insulation castables for dry-type outdoor electric complete sets of equipment are composed of the following raw materials:

[0036] EHL-55A Modified High Purity Flexible Cycloaliphatic Epoxy Resin

100 parts (weight ratio)

EHLS-60 modified methyl hexahydrophthalic anhydride

83 copies

EHLP-200 reactive toughening agent

18.5 servings

[0037] N,N benzyldimethylamine accelerator

0.25 parts

EHLA-400 coupled silica powder

325 copies

LA epoxy stain

2 copies

[0038] 2. The preparation method of the insulating castable for dry-type outdoor electric complete sets of the present invention is as follows:

[0039] a. First, weigh each raw material according to the above weight components, preheat the epoxy resin at 95°C for 1.2 hours, add EHLA-400 coupled silica powder, EHLP-200 reactive toughening agent, EHLS-60 modified formaldehyde Base hexahydrophthalic anhydride, N. N benzyldimethylamine a...

Embodiment 3

[0046]1. Insulation castables for dry-type outdoor electric complete sets of equipment are composed of the following raw materials:

[0047] EHL-55A Modified High Purity Flexible Cycloaliphatic Epoxy Resin

100 parts (weight ratio)

EHLS-60 modified methyl hexahydrophthalic anhydride

85 copies

EHLP-200 reactive toughening agent

20 copies

[0048] N,N benzyldimethylamine accelerator

0.3 parts

EHLA-400 coupled silica powder

350 copies

LA epoxy stain

3 copies

[0049] 2. The preparation method of the insulating castable for dry-type outdoor electric complete sets of the present invention is as follows:

[0050] a. First, weigh each raw material according to the above weight components, preheat the epoxy resin at 100°C for 1 hour, add EHLA-400 coupled silica powder, EHLP-200 reactive toughening agent, EHLS-60 modified formaldehyde Base hexahydrophthalic anhydride, N. N benzyldimethylamine accelera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com