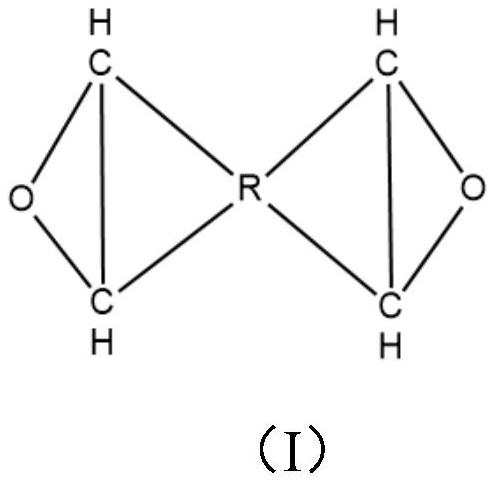

A high-efficiency flame-retardant alicyclic epoxy resin castable for outdoor insulators

An epoxy resin, alicyclic technology, applied in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of low oxygen index of alicyclic epoxy resin, limit the application in the field of high voltage insulation, etc., to achieve flame retardant performance Improved, good outdoor weather resistance, excellent heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

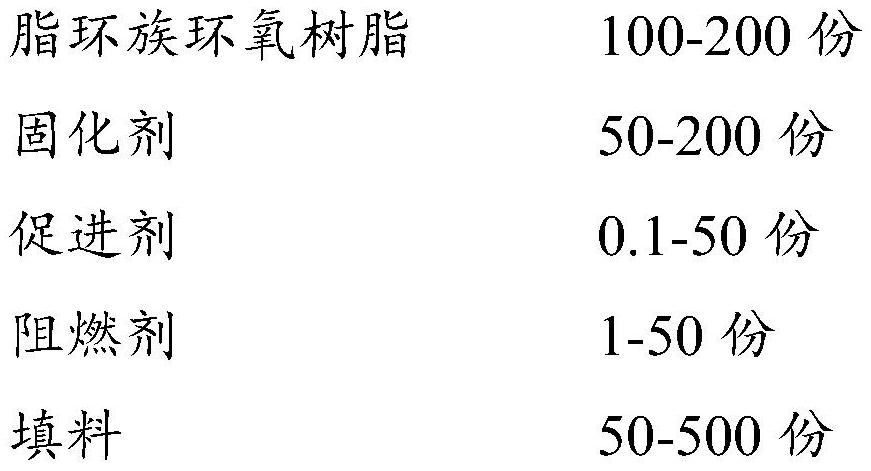

[0035] A high-efficiency flame-retardant cycloaliphatic epoxy resin castable for outdoor insulators, comprising the following components, all parts are by weight:

[0036]

[0037] The preparation method of the castable of the present embodiment comprises the following steps:

[0038] (1) Take each component raw material in proportion;

[0039] (2) After alicyclic glycidyl type epoxy resin and methyltetrahydrophthalic anhydride are stirred evenly, flame retardant, aluminum hydroxide and color paste are added to stir evenly, amine accelerator is added, and stirring is continued to obtain the high-efficiency Flame retardant cycloaliphatic epoxy castable for outdoor insulators.

Embodiment 2

[0041] A high-efficiency flame-retardant cycloaliphatic epoxy resin castable for outdoor insulators, comprising the following components, all parts are by weight:

[0042]

[0043]

[0044] The preparation method of the castable of the present embodiment comprises the following steps:

[0045] (1) Take each component raw material in proportion;

[0046] (2) After alicyclic glycidyl epoxy resin and methyltetrahydrophthalic anhydride are stirred evenly, flame retardants, fillers and colorants are added to stir evenly, amine accelerators are added, and stirring is continued to obtain the high-efficiency flame-retardant Cycloaliphatic epoxy resin castable for outdoor insulators.

Embodiment 3

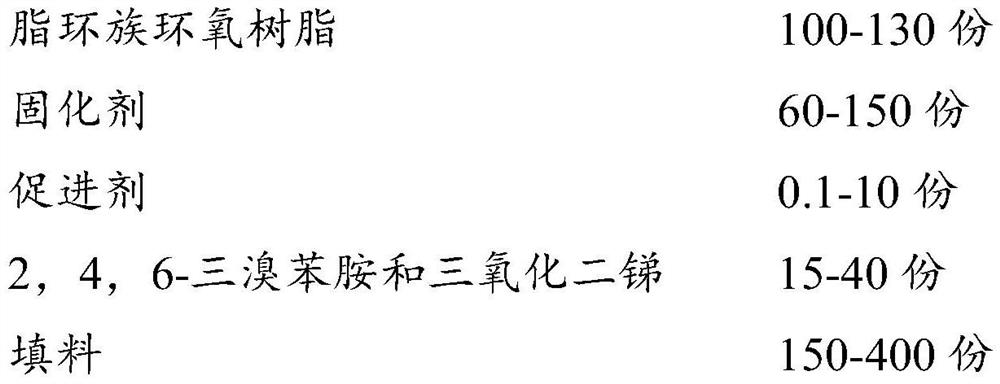

[0048] A high-efficiency flame-retardant cycloaliphatic epoxy resin castable for outdoor insulators, comprising the following components, all parts are by weight:

[0049]

[0050] The weight ratio of 2,4,6-tribromoaniline to antimony trioxide is 2.2:1.

[0051] The preparation method of the castable of the present embodiment comprises the following steps:

[0052] (1) Take each component raw material in proportion;

[0053] (2) After alicyclic glycidyl type epoxy resin and methyltetrahydrophthalic anhydride are stirred evenly, flame retardant, aluminum hydroxide and color paste are added to stir evenly, amine accelerator is added, and stirring is continued to obtain the high-efficiency Flame retardant cycloaliphatic epoxy castable for outdoor insulators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com