A stepless speed regulator

A technology of stepless speed regulation and transmission disc, which is applied in clutches, fluid clutches, belts/chains/gears, etc. It can solve the problems of power reduction, large slip rate, poor resistance to overload and impact resistance, etc., to achieve stable output power, The effect of fast speed regulation response and wide speed regulation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

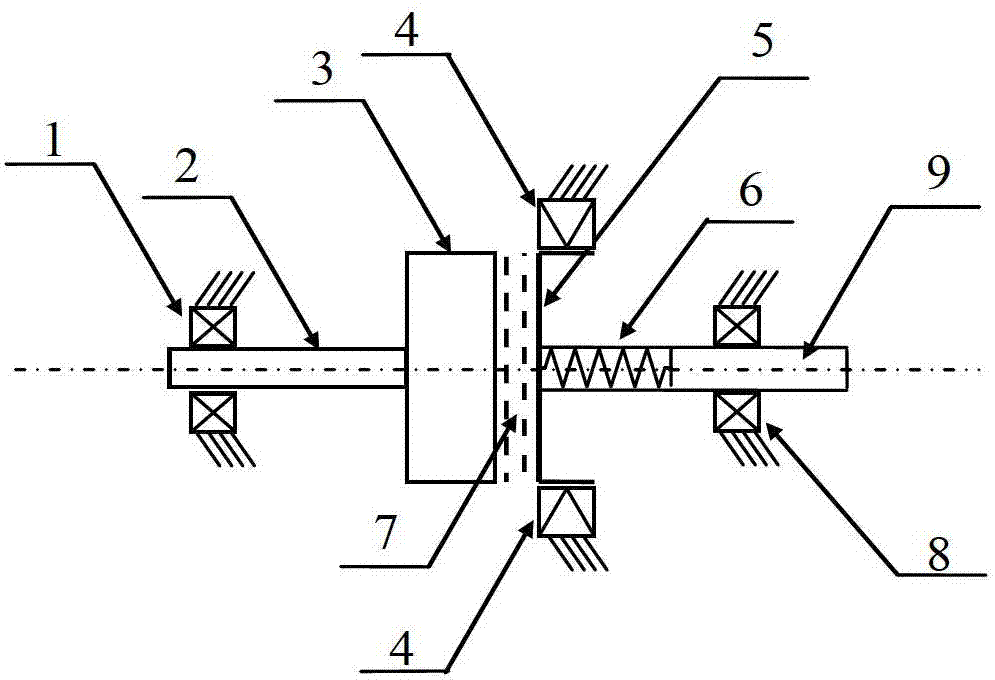

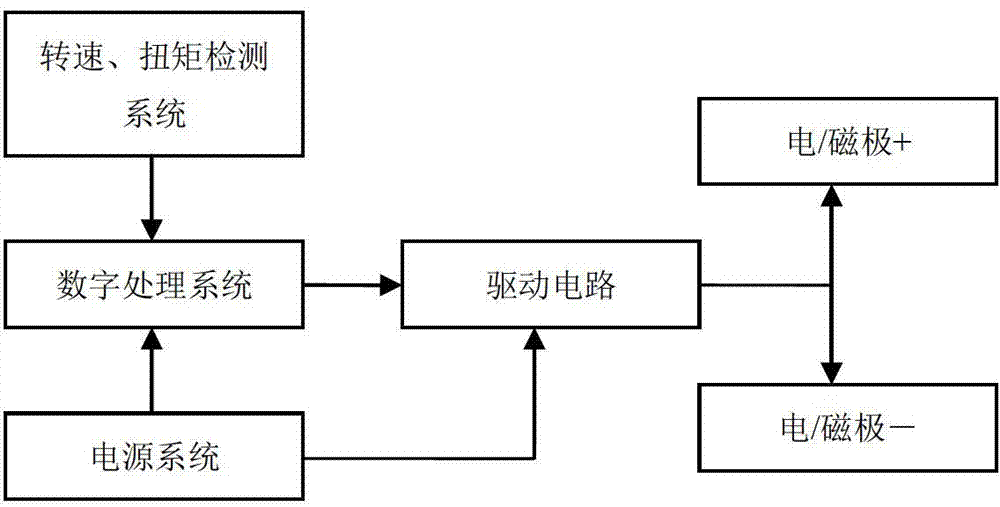

[0039] like figure 1 As shown, a stepless speed regulator includes an input system, a transmission system and an output system arranged coaxially and in series. The input system includes an input shaft locating bearing 1, an input shaft 2 and an energy storage flywheel 3, the variable speed transmission system includes a medium 7, a transmission disc 5 and a ratchet 4, and the output system includes a torsion spring 6, an output shaft locating bearing 8 and output shaft 9. Medium 7 is electrorheological fluid.

[0040] The input shaft locating bearing 1 is embedded with the input shaft 2 for fixing the input shaft 2 ; the output shaft locating bearing 8 is embedded with the output shaft 9 for fixing the output shaft 9 .

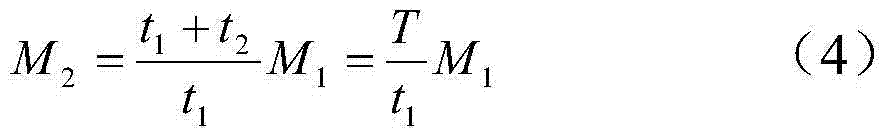

[0041]The input shaft 2 is rigidly connected with the energy storage flywheel 3 coaxially. The medium 7 is placed between the energy storage flywheel 3 and the transmission disc 5. When a voltage is applied, the medium 7 will solidify, thereby connecting t...

Embodiment 2

[0048] The medium 7 is an electromagnetic variable fluid, and the others are the same as in Embodiment 1. The surface of the energy storage flywheel 3 and the transmission disc 5 is treated with magnetic isolation.

Embodiment 3

[0050] The medium 7 is a controllable magnetic powder, and the others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com