Manufacturing equipment of layered metal composite board and method adopting same

A layered metal and manufacturing equipment technology, applied in the field of manufacturing equipment of layered metal composite panels, can solve the problems of difficult process control, non-continuous production, complex equipment structure, etc., and achieve a wide range of thickness changes, high production efficiency, The effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: Preparation of stainless steel and steel clad plate:

[0031] In this embodiment, the stainless steel clad plate is made of 0Cr13 stainless steel and 20# ordinary carbon steel.

[0032] 0Cr13 stainless steel is corrosion-resistant, and 20# ordinary carbon steel is low in cost. The thickness of 0Cr13 stainless steel / 20# steel composite plate is 5mm / 25mm, which is widely used in chemical industry, military and other fields.

[0033] The steps to prepare 0Cr13 stainless steel / 20# steel clad plate are as follows:

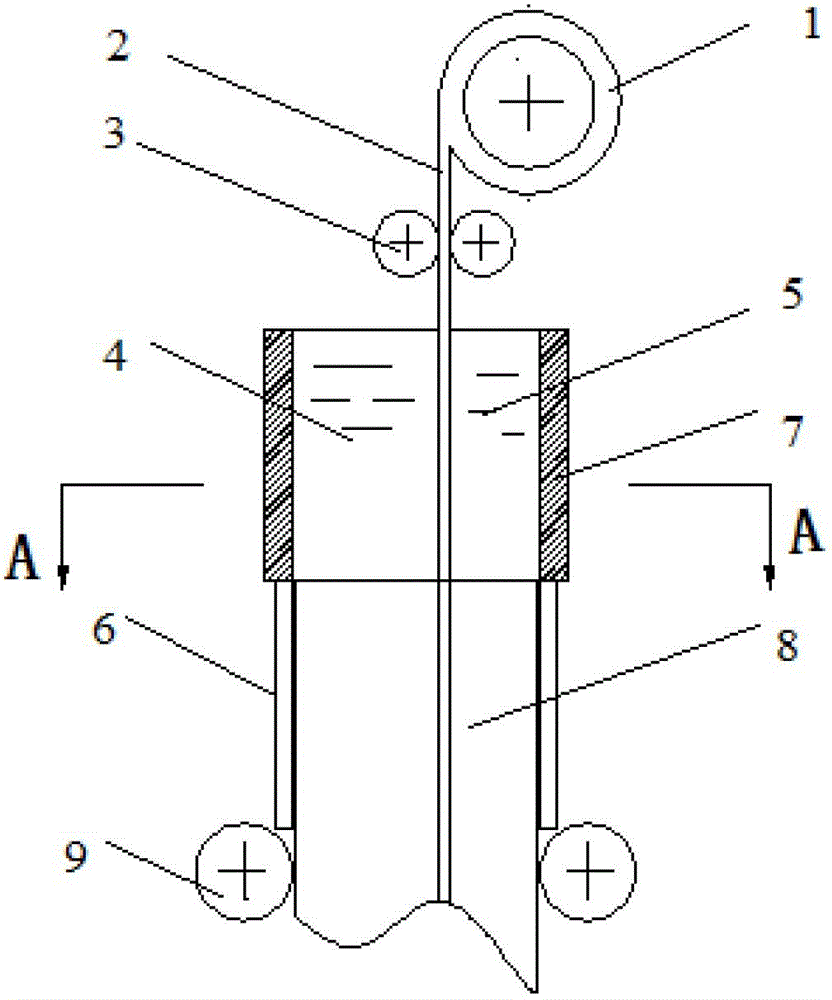

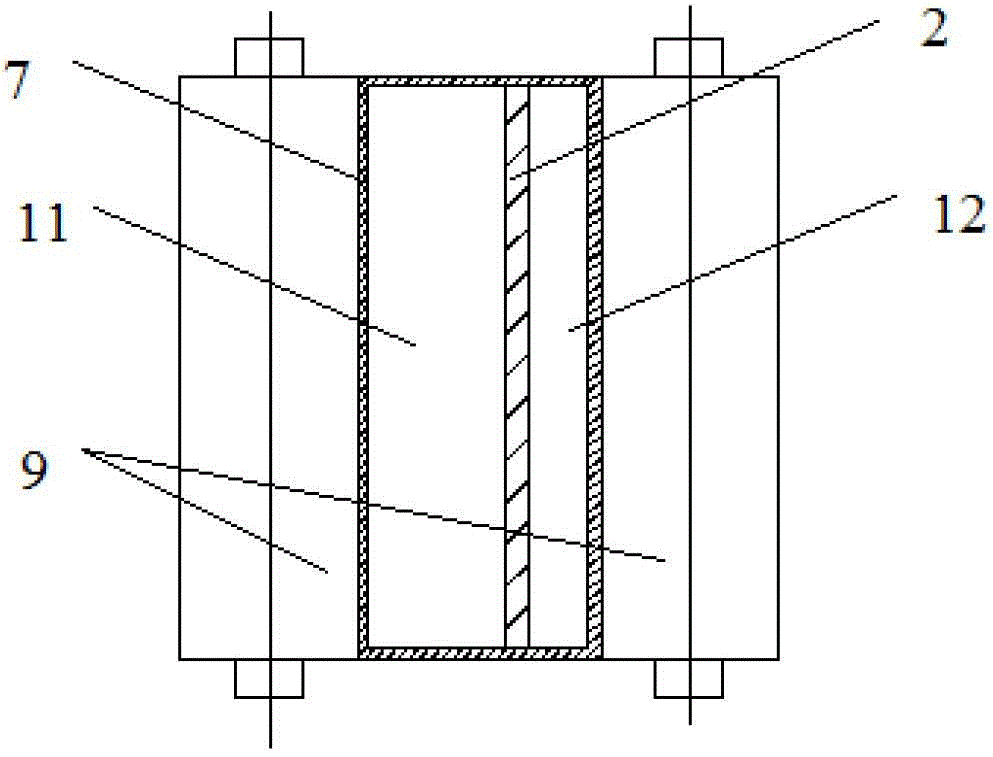

[0034] 1. Select 20# ordinary carbon steel sheet as the thin composite substrate 2 (hereinafter referred to as 20# ordinary carbon steel sheet), the width of which is the same as that of the composite sheet to be prepared, and the thickness is 0.5mm.

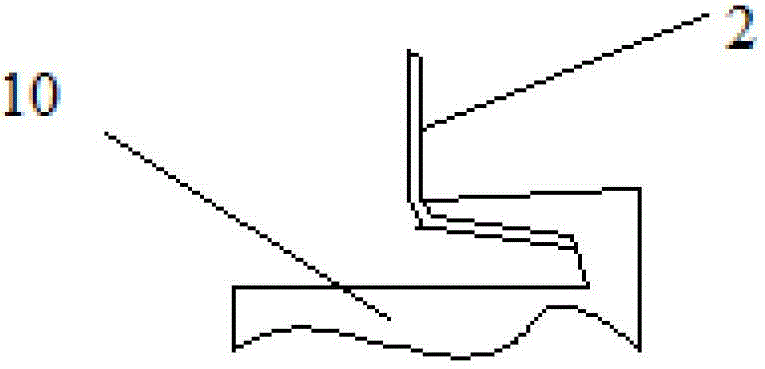

[0035] 2. Adjust the crystallizer 7 so that the width of the inner chamber of the crystallizer 7 is 30mm, and the dummy rod 10 is blocked at the lower opening of the crystallizer 7 to form a molten ...

Embodiment 2

[0041] Embodiment 2: Preparation of steel / aluminum composite panel:

[0042] In this embodiment, the steel / aluminum composite plate is made of Q235 ordinary carbon steel and LY12 aluminum, and its thickness is 30mm / 10mm. It has the characteristics of high hardness, high brittleness, and high melting point of steel, and has excellent properties such as corrosion resistance, high electrical conductivity, high thermal conductivity, low density, and low cost of aluminum. It can be used as a subway power transmission induction plate. Compared with other materials, it can ensure electrical conductivity and low cost while being able to withstand large loads. Using its characteristics of corrosion resistance, high electrical conductivity and low cost, it is used in electrolytic aluminum, aluminum smelting and other fields. .

[0043] The steps to prepare Q235 / LY12 composite board are as follows:

[0044] 1. Select Q235 ordinary carbon steel sheet as the thin composite substrate 2 (h...

Embodiment 3

[0050]Example 3: Preparation of cast iron / steel bimetal composite plate

[0051] This example adopts 45# ordinary carbon steel and KMTBCr20Mn2Cu high chromium cast iron, and the thickness is 20mm / 8mm cast iron / 45# steel bimetal composite plate, among which cast iron is high manganese steel, white cast iron, chromium series anti-wear cast iron, etc. The material can greatly improve the wear resistance of the machine parts, but it also has disadvantages, such as white cast iron and chromium-based wear-resistant cast iron, which are relatively brittle and have poor impact resistance, and are safe under conditions of high impact. Poor performance and stability, prone to breakage or peeling; high manganese steel has poor abrasive wear resistance and low yield strength, which can easily cause the mill liner to fall off due to broken bolts, and most of the wear-resistant castings have relatively weak structures. It is bulky, cannot be welded, and is inconvenient for transportation an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com