Lignite thermal power generation system

A lignite and drying machine technology, applied in the direction of combustion method, use of liquid separation agent, lighting and heating equipment, etc., can solve the problems of dust removal treatment defects, complicated operation of power generation process, and inconvenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

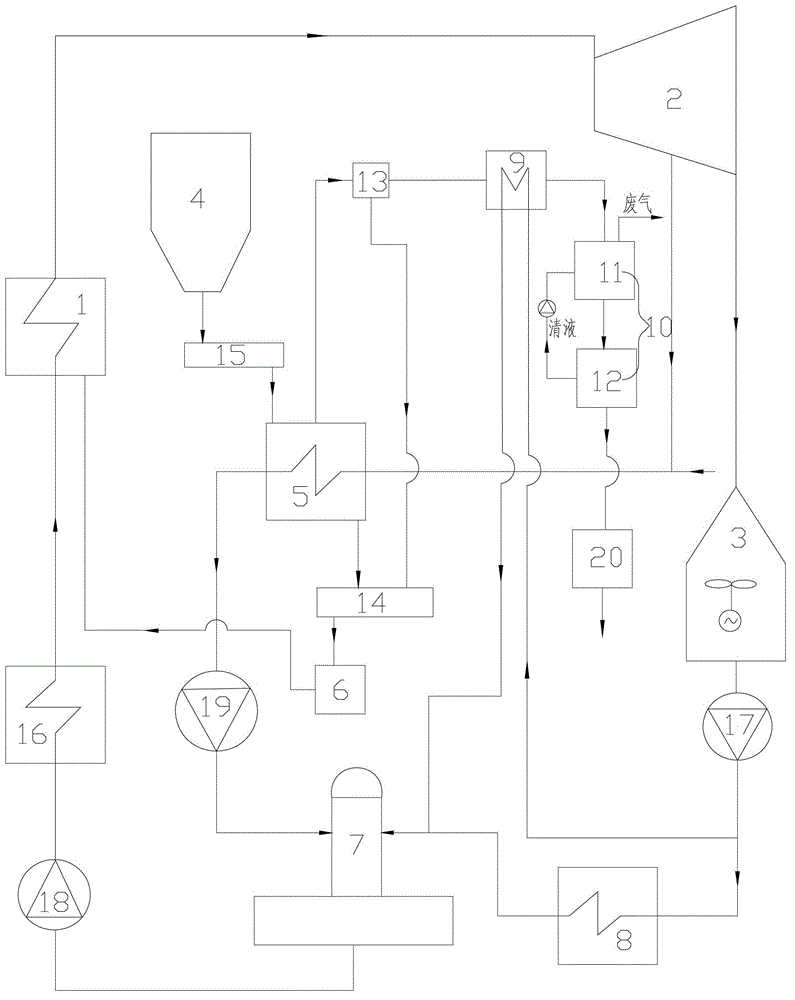

[0044] Such as figure 1 As shown, as an embodiment of the present invention, preferably, the water purification device 10 includes a wet dust collector 11 and a sedimentation device 12, the liquid inlet of the wet dust collector 11 is connected to the exhaust of the heat exchanger 9 The liquid outlet is connected, the liquid discharge port of the wet dust collector 11 is connected with the liquid inlet of the precipitation device 12, the clear liquid outlet of the precipitation device 12 is connected with the clear liquid inlet of the wet dust collector 11, and the The wet dust collector 11 also has an exhaust port.

[0045] After the exhaust gas is heat-exchanged in the heat exchanger 1, the water vapor in the exhaust gas condenses to form a liquid mixture due to the low temperature. 11 exhaust ports are discharged.

[0046] The dusty wastewater enters the sedimentation device 12 for sedimentation treatment, so that the impurities in it settle to the bottom to form a turbid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com