Preparation method and use of fluorescent carbon quantum dot/polyacrylonitrile nanofiber membrane

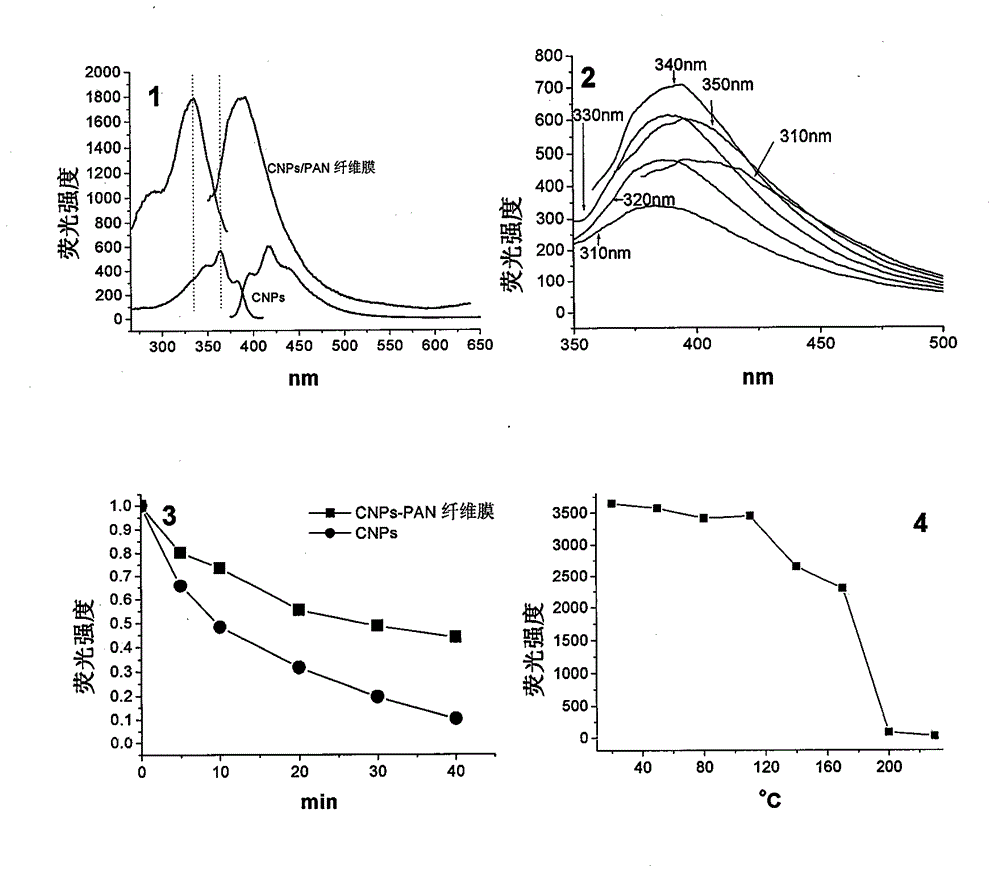

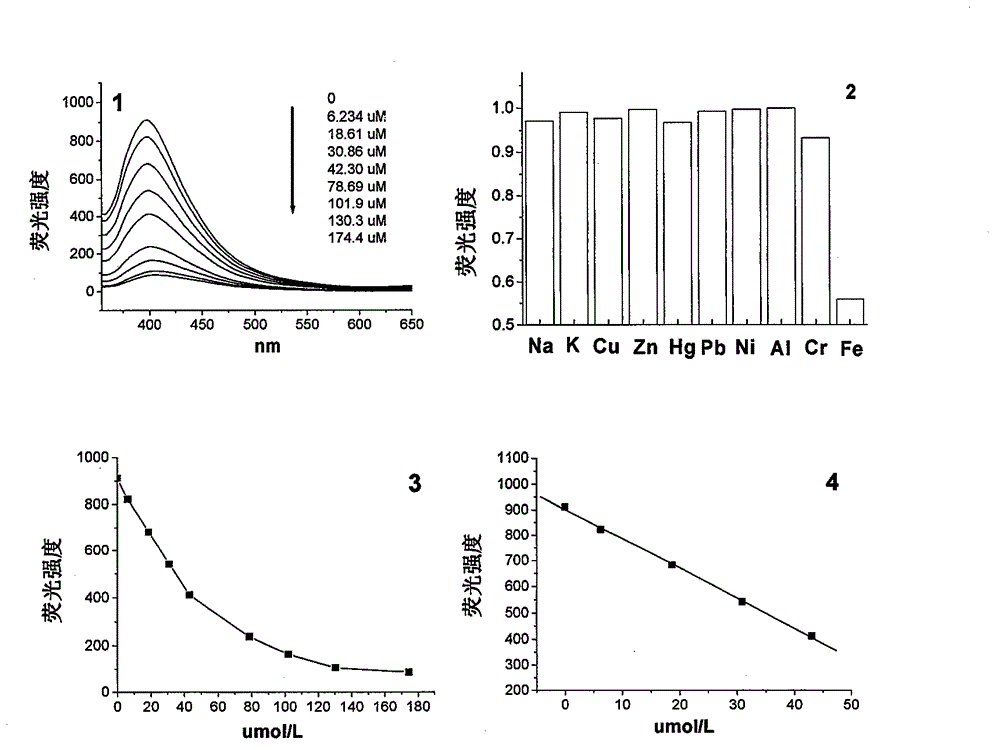

A nanofiber membrane and polyacrylonitrile technology, which is applied in the direction of fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems of separation and recovery of fluorescent carbon quantum dot materials, and achieve improved photobleaching resistance, good thermal stability, Effect of Good Optical Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

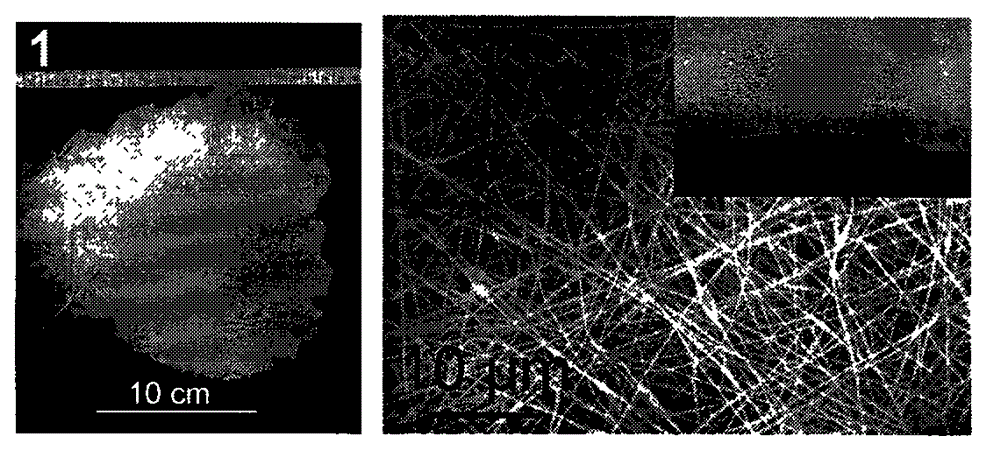

[0019] a. Weighing 1g of polyacrylonitrile powder with a molecular weight of 50,000 and 0.2g of fluorescent carbon quantum dots was dissolved in 10g of dimethylformamide under stirring to obtain a polyacrylonitrile viscous solution;

[0020] b. Put the viscous solution into a syringe with a capillary, insert the copper wire connected to the high-voltage generator into the solution, and use the aluminum foil as the receiving electrode. After adjusting the angle and distance between the capillary of the syringe and the receiving device of the aluminum foil, add 10kV to the solution The voltage is spun to obtain the crude product fluorescent carbon quantum dot / polyacrylonitrile nanofiber membrane;

[0021] c. Washing the fluorescent carbon quantum dot / polyacrylonitrile nanofiber membrane obtained in step b with distilled water three times to remove the residual solvent dimethylformamide to obtain the fluorescent carbon quantum dot / polyacrylonitrile nanofiber membrane.

Embodiment 2

[0023] a. Take 1g of polyacrylonitrile powder with a molecular weight of 80,000 and 5.1g of fluorescent carbon quantum dots and dissolve it in 38g of dimethylformamide under stirring to obtain a polyacrylonitrile viscous solution;

[0024] b. Put the viscous solution into a syringe with a capillary, insert the copper wire connected to the high-voltage generator into the solution, and use the aluminum foil as the receiving electrode. After adjusting the angle and distance between the capillary of the syringe and the receiving device of the aluminum foil, add Spinning at a voltage of 30kV to obtain a crude fluorescent carbon quantum dot / polyacrylonitrile nanofiber membrane;

[0025] c. Wash the fluorescent carbon quantum dot / polyacrylonitrile nanofiber membrane obtained in step b with deionized water three times to remove the residual solvent dimethylformamide to obtain the fluorescent carbon quantum dot / polyacrylonitrile nanofiber membrane.

Embodiment 3

[0027] a. Weighing 1g of polyacrylonitrile powder with a molecular weight of 150,000 and 1.0g of fluorescent carbon quantum dots was dissolved in 5g of dimethylformamide under stirring to obtain a polyacrylonitrile viscous solution;

[0028] b. Put the viscous solution into a syringe with a capillary, insert the copper wire connected to the high-voltage generator into the solution, and use the aluminum foil as the receiving electrode. After adjusting the angle and distance between the capillary of the syringe and the receiving device of the aluminum foil, add 5kV to the solution The voltage is spun to obtain the crude product fluorescent carbon quantum dot / polyacrylonitrile nanofiber membrane;

[0029] c. Wash the fluorescent carbon quantum dot / polyacrylonitrile nanofiber membrane obtained in step b with ultrapure water for 3 times, and remove the residual solvent dimethylformamide to obtain the fluorescent carbon quantum dot / polyacrylonitrile nanofiber membrane.

[0030] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com