Plane solid high-voltage switch

A high-voltage switch, solid technology, applied in electrical components, spark gaps, spark gap components and other directions, can solve the problem of unstable performance of gas-insulated high-voltage switches, and achieve easy integration, fewer processes, and improved safety and reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

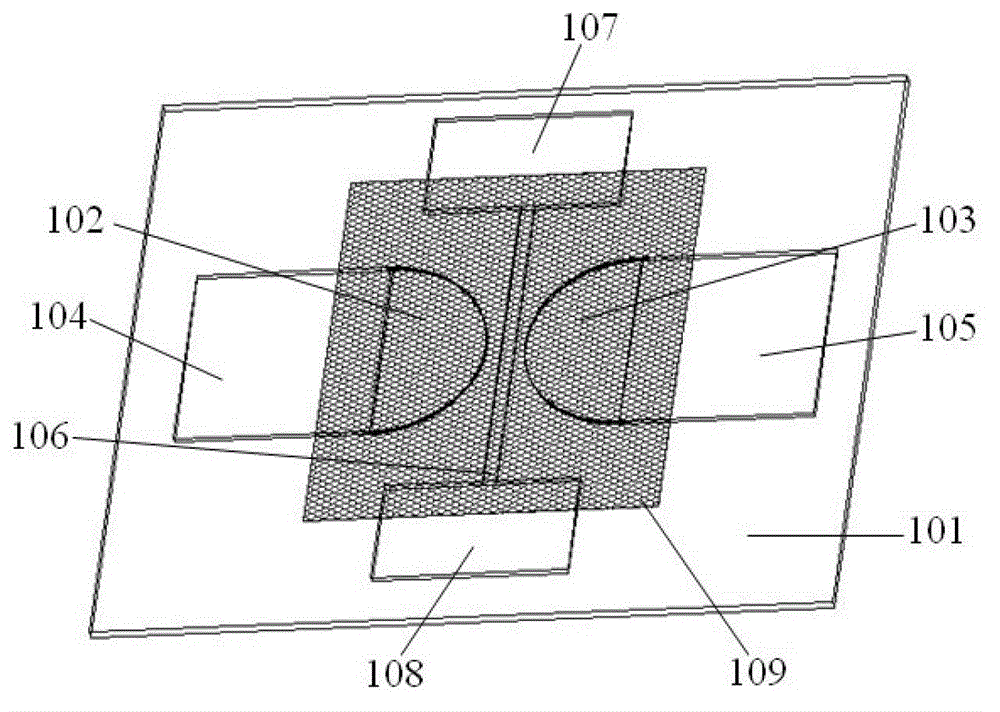

[0035] refer to figure 1 , showing a schematic diagram of a planar solid high voltage switch of the present invention, this embodiment may specifically include:

[0036] Insulating substrate 101, positive electrode 102, negative electrode 103, positive electrode welding plate 104, negative electrode welding plate 105, trigger electrode 106, trigger electrode welding plate 107, trigger electrode welding plate 108 and insulating layer 109;

[0037] Wherein, the positive electrode 102, the negative electrode 103, the positive electrode welding plate 104, the negative electrode welding plate 105, the trigger electrode 106, the trigger electrode welding plate 107 and the trigger electrode welding plate 108 are located on the surface of the insulating base 101, and the insulating layer 109 covers the positive electrode. Electrode 102, negative electrode 103 and trigger electrode 106 between positive electrode 102 and negative electrode 103; Positive electrode welding plate 104 is co...

Embodiment 2

[0050] refer to Figure 4 , shows the application circuit diagram of the planar solid high-voltage switch of the present invention, and this embodiment may specifically include:

[0051] Insulating substrate 401, positive electrode 402, negative electrode 403, positive electrode welding plate 404, negative electrode welding plate 405, trigger electrode 406, trigger electrode welding plate 407, trigger electrode welding plate 408, insulating layer 409 and the capacitor connected when the switch is in use 410. Trigger the power supply 411 and the electronic switch 412.

[0052] Wherein, the positive electrode 402, the negative electrode 403, the positive electrode welding plate 404, the negative electrode welding plate 405, the trigger electrode 406, the trigger electrode welding plate 407 and the trigger electrode welding plate 408 are located on the surface of the insulating base 401, and the insulating layer 409 covers the positive electrode. Electrode 402, negative electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com