Wood preservative formulations comprising isothiazolones which provide protectin against surface staining

一种异噻唑酮、木材防腐的技术,应用在木材处理、浸渍木材、木材浸渍等方向,能够解决不提供防表面变色等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0196] A field trial was initiated in which various formulations were tested for their ability to maintain wood in a discolored and mold-free condition for an extended period of time.

[0197] The formulation was prepared by adding all water-insoluble components (e.g., azoles, isothiazolones, any insoluble acids, etc.) to a solvent (Downer (Dowanol )) and stir until all dissolved. Then, the surfactant is added with stirring, followed by the water. Add any water-soluble additives (eg, sodium benzoate) last.

[0198] "a.i." as used in these examples is the active ingredient.

[0199] The following products are used for each active ingredient.

[0200] Prevent (Preventol ) (95% a.i. Tebuconazole)

[0201] Watson (Wocosen ) (50% a.i. propiconazole)

[0202] Viquins (Vanquish ) (99% a.i. BBIT)

[0203] Exeterside (Acticide ) (45% a.i. OIT)

[0204] Exeterside (Acticide ) (20% a.i. BIT)

[0205] The formulations used for testing are as follows (all value...

Embodiment 2

[0273] The following formulations were formulated and tested using the same protocol as described in Example 1.

[0274] Formulation II-1

[0275]

[0276]

[0277] When applied to wood, dilute to equal 100ppm OIT.

[0278] Formulation II-2

[0279]

[0280] When applied to wood, dilute to equal 100ppm OIT.

[0281] Formulation II-3

[0282]

[0283] When applied to wood, dilute to equal 100ppm OIT.

[0284] Formulation II-4

[0285]

[0286] Diluted to equal 100ppm OIT, then combined with 0.03w / w abietic acid and applied to wood.

[0287] Formulation II-5

[0288]

[0289] Dilute to equal 100ppm OIT, then combine with 0.03w / w sodium salicylate and apply to wood.

[0290] Formulation II-6

[0291]

[0292] Diluted to equal 100ppm OIT, then combined with 0.03w / w oleic acid and applied to wood.

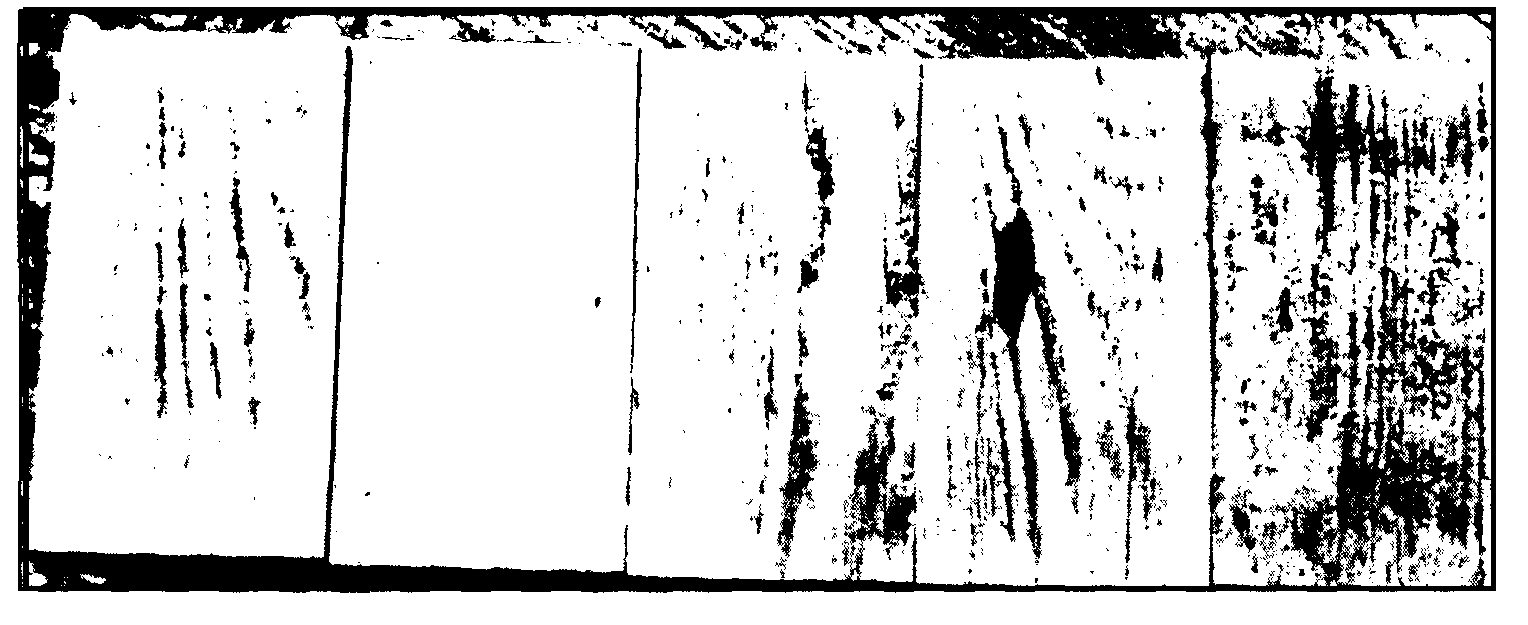

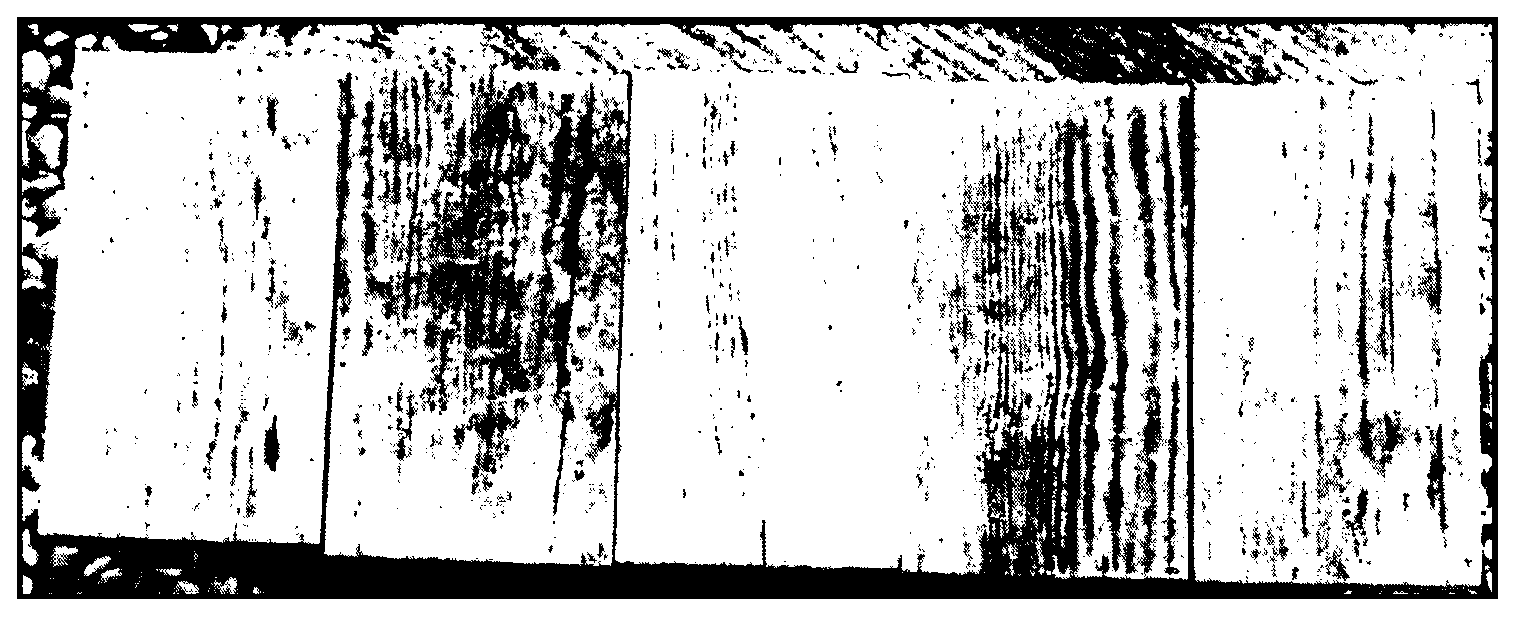

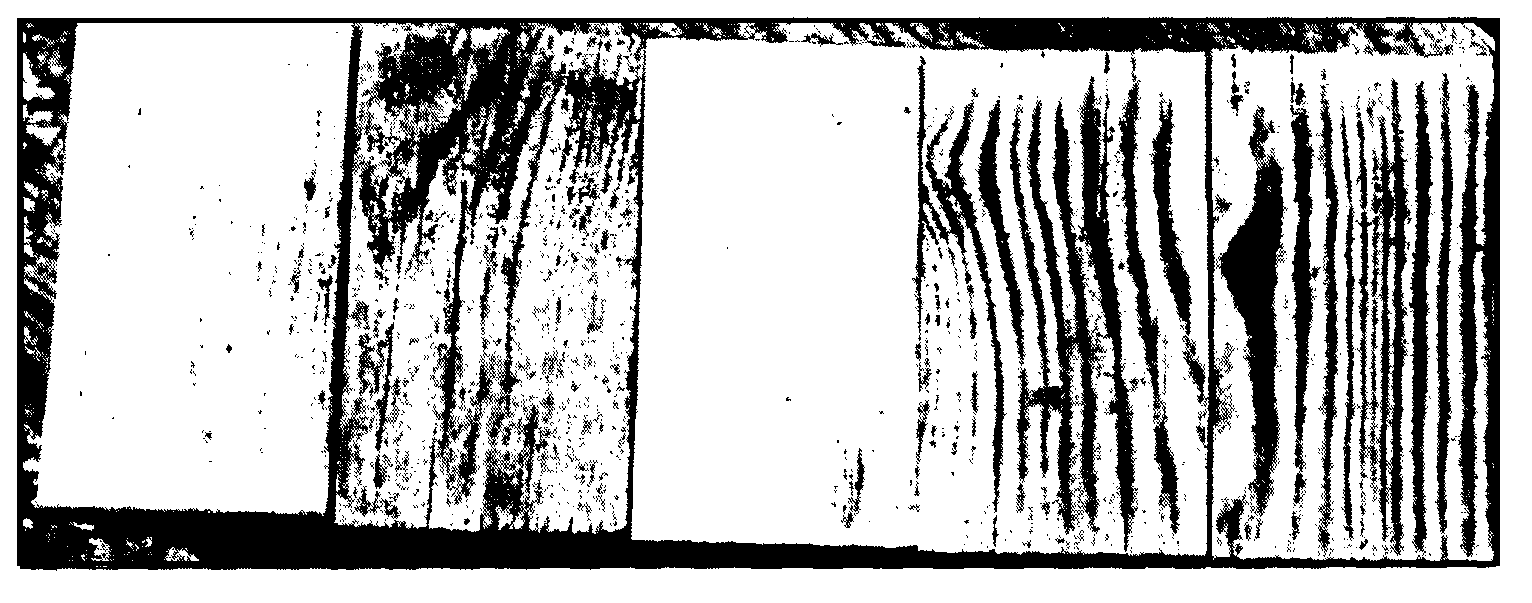

[0293] Respectively Figures 13 to 18 Photographs are shown of wood treated with formulations II-1 to II-6 after 25 weeks of exposure. From these figures i...

Embodiment 3

[0295] The pine edge board pieces were cut into 134x68x20mm pieces which were then treated with a wood preservative treatment solution. The formulation was applied to the blocks by wet vacuum at 80 kPa (600 mmHg) for 45 minutes in the treatment solution, followed by 1 hour at 1.2 MPa (12 bar) pressure. According to the average retention target of the treatment solution (retention target) is 650kg / m 3 to process the block.

[0296] The following products are used for each active ingredient:

[0297]

[0298] The formulations used for testing were as follows (all values are given in %w / w):

[0299] Formulation III-1-1 (comparison)

[0300]

[0301]

[0302] This concentrate is then diluted to 0.45% with water.

[0303] Formulation III-1-2 (comparison)

[0304]

[0305] This concentrate is then diluted to 0.45% with water.

[0306] Formulation III-1-3 (comparison)

[0307]

[0308] This concentrate is then diluted to 0.45% with water.

[0309] Formulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com