Method for preparing peptide used for active feed by bacteria and enzyme synergistic fermentation bean pulp

A technology of synergistic fermentation and feed peptide, applied in the application, animal feed, animal feed, etc., can solve the problems of the digestibility of soybean meal material and the decrease of animal absorption rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

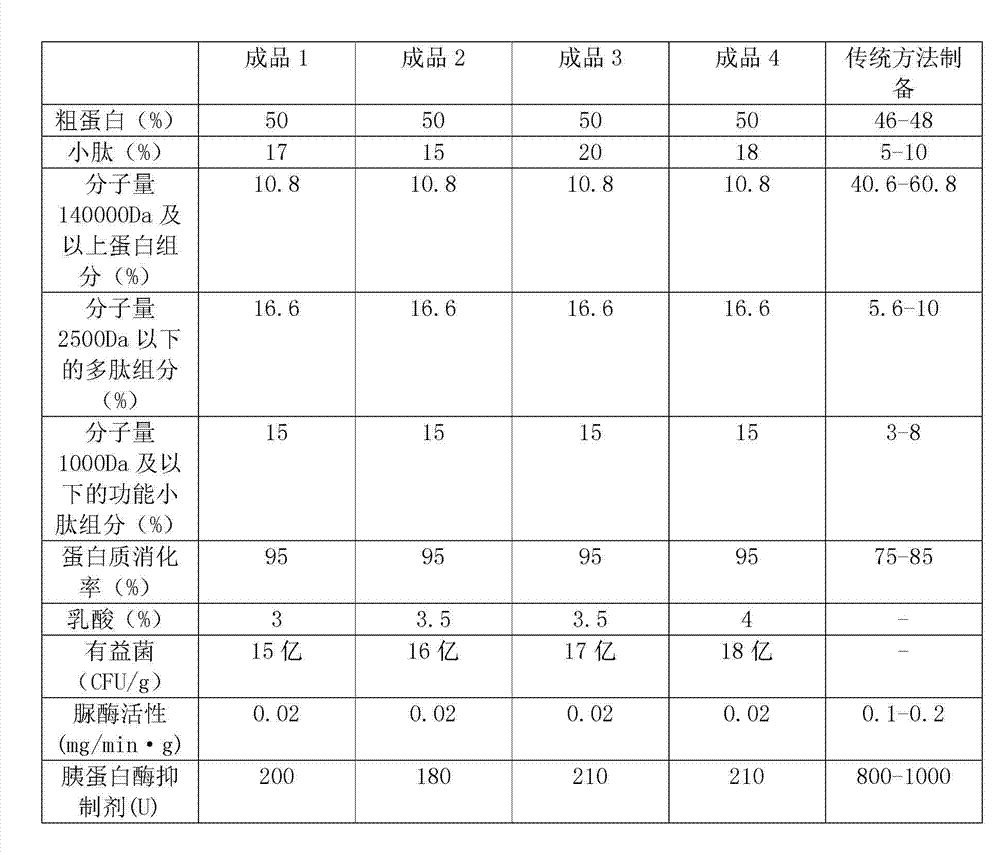

Examples

Embodiment 1

[0031] Embodiment 1: A method for preparing active feed peptides by fermenting soybean meal with enzymes, comprising the following steps:

[0032] A) A total of 10kg of compound enzymes used for the preparation of collaborative fermentation. The compound enzyme includes neutral protease, acid protease, alkaline protease, non-starch polysaccharide enzyme, pectinase and xylanase. Among them, neutral protease, acid protease and alkaline protease are secreted by Bacillus or Aspergillus niger. Meanwhile, the parts by weight of each component are: 15 parts of neutral protease, 10 parts of acid protease, 8 parts of alkaline protease, 18 parts of non-starch polysaccharide enzyme, 6 parts of pectinase and 3 parts of xylanase. During the preparation, the compound enzyme was activated by warm water at 40oC for 1 hour. During the activation, stir well to make all kinds of enzymes mix evenly and fully dissolve.

[0033] B) Prepare 10kg of composite strains for collaborative fermentation...

Embodiment 2

[0042] Example 2: The method of enzyme synergistic fermentation of soybean meal to prepare active feed peptides, the only difference from Example 1 is:

[0043] In step A), in parts by weight, the parts by weight of the components in the compound enzyme used for the synergistic fermentation are: 20 parts of neutral protease, 15 parts of acid protease, 12 parts of alkaline protease, 24 parts of non-starch polysaccharide enzyme, fruit 11 parts of gluease, 8 parts of xylanase. During the preparation, the compound enzyme was activated by warm water at 45oC for 1.5h. During the activation, stir well to make all kinds of enzymes mix evenly and fully dissolve.

[0044]In step B), in parts by weight, the parts by weight of the components of the composite bacteria used for the synergistic fermentation are: 20 parts of Bacillus lentus, 30 parts of Candida utilis, and 30 parts of Lactobacillus fermentum. During the preparation, each bacterial strain of the composite bacterial strain is...

Embodiment 3

[0053] Example 3: The method of enzyme synergistic fermentation of soybean meal to prepare active feed peptides, the only difference from Example 1 is:

[0054] In step A), in parts by weight, the parts by weight of the components in the compound enzyme used for the synergistic fermentation are: 23 parts of neutral protease, 18 parts of acid protease, 16 parts of alkaline protease, 26 parts of non-starch polysaccharide enzyme, fruit 13 parts of gluease, 2 parts of xylanase. During preparation, the complex enzyme was activated by warm water at a temperature of 50°C for 2 hours. During the activation, stir well to make all kinds of enzymes mix evenly and fully dissolve.

[0055] In step B), in parts by weight, the parts by weight of the components of the composite bacteria used for the synergistic fermentation are: 27 parts of Bacillus lentus, 36 parts of Candida utilis, and 35 parts of Lactobacillus fermentum. During the preparation, each bacterial strain of the composite bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com