Thiol functionalization method and application of nano hole metal-organic framework material

An organic framework, nano-hole technology, applied in the direction of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of weak interaction and weak adsorption capacity of heavy metal ions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

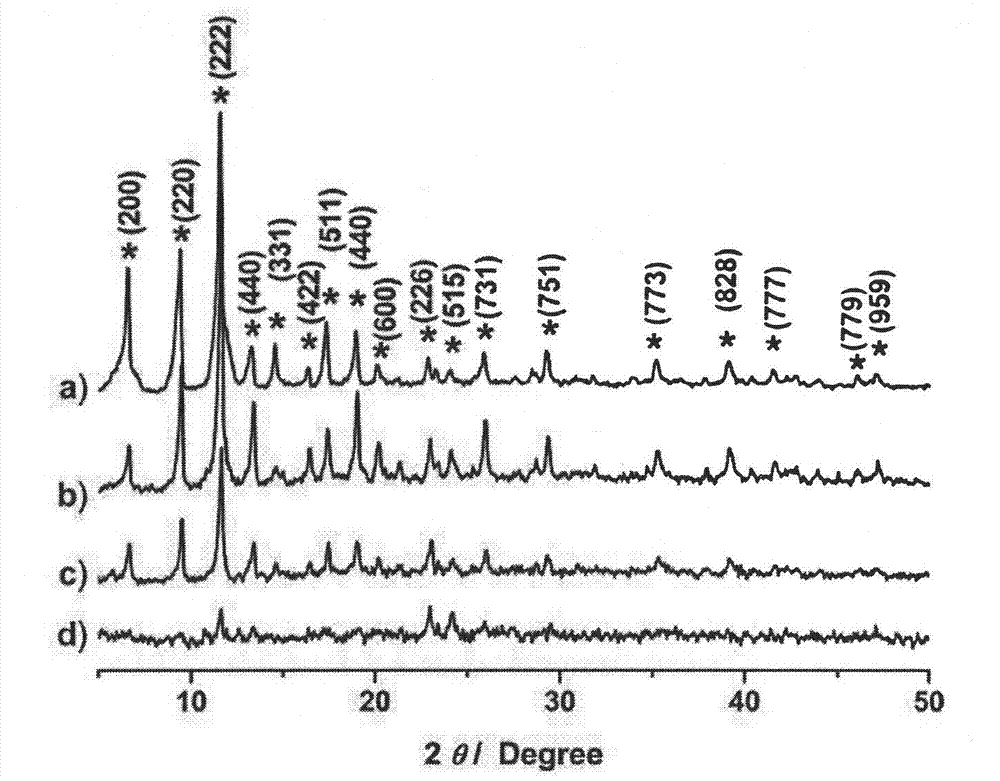

[0024] Unmodified nanoporous [Cu 3 (BTC) 2 (H 2 O) 3 ] n The metal-organic framework material was synthesized with reference to the method provided by Chui S.S.-Y. et al. in Science 1999, No. 283, pp. 1148-1150. Weigh 1.087g of copper nitrate trihydrate, dissolve it in 15ml of water, then weigh 0.525g of 1,3,5-benzenetricarboxylic acid, dissolve it in 15ml of ethanol, mix the two solutions and continue to stir for 30 minutes, then mix all The solution was transferred into an autoclave, and reacted at 120 degrees Celsius for 12 hours. The blue product was filtered, washed with water, and then washed with ethanol, and then put into a drying oven to dry at 150 degrees Celsius for 4 hours. The obtained product was characterized by powder X-ray diffraction, and its structure was consistent with the nanoporous metal-organic framework material [Cu 3 (BTC) 2 (H 2 O) 3 ] n exactly the same (see figure 1 (a)).

[0025] The nanopores [Cu 3 (BTC) 2 (H 2 O) 3 ] n The metal-...

Embodiment 2

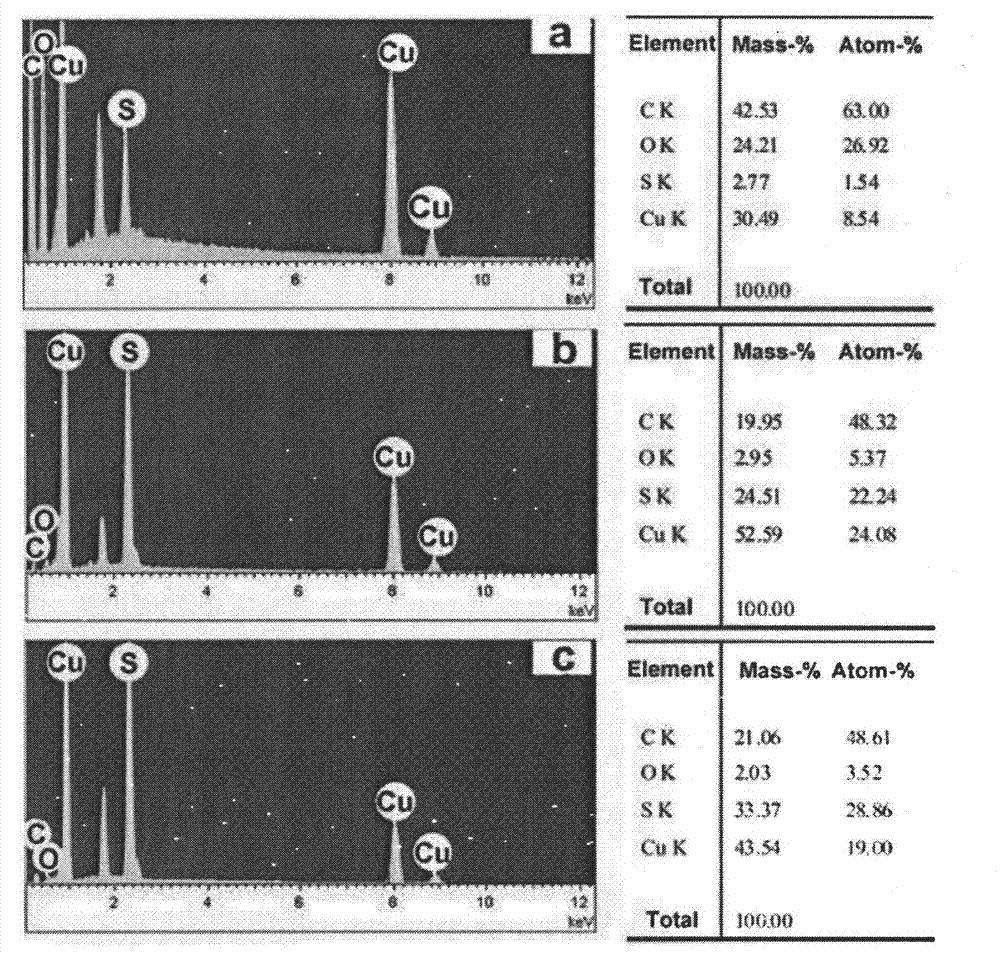

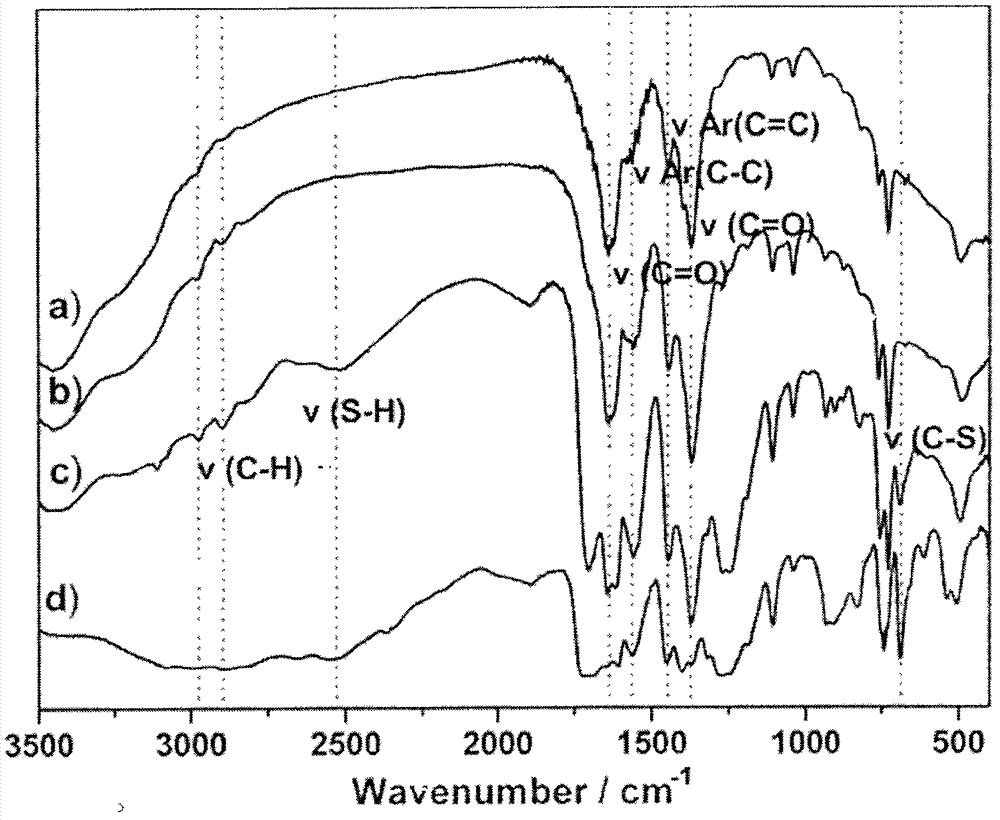

[0028] Take by weighing the nano hole [Cu] made in embodiment 1 3 (BTC) 2 ] n Metal-organic framework material 0.1g, disperse it in 10ml of anhydrous toluene, add 1.0ml of prepared 0.24mol / L ethanedithiol in the family, stir at room temperature for 24 hours, after the product is filtered, ethanol (15ml×5) was washed, and vacuum-dried at room temperature (vacuum degree 0.1MPa) for 12 hours. The prepared mercapto-functionalized nanopores [Cu 3 (BTC) 2 ] n Metal-organic frameworks were characterized by powder X-ray diffraction (see figure 1 (c)), its structure is similar to that of the nanoporous metal-organic framework [Cu 3 (BTC) 2 (H 2 O) 3 ] n Exactly the same; its BET specific surface area was determined to be 331m 2 / g, pore volume 0.18cm 3 / g, the pore size distribution is determined to be 0.4-0.7nm; its infrared spectrum ( image 3 (b)) proves that there are two kinds of thiol functional groups in the ethanedithiol molecule, namely: the thiol that coordinates...

Embodiment 3

[0030] Take by weighing the nano hole [Cu] made in embodiment 1 3 (BTC) 2 ] n Metal-organic framework material 0.1g, disperse it in 10ml of anhydrous toluene, add 1.5ml of prepared 0.24mol / L ethanedithiol, and stir at room temperature for 24 hours, after the product is filtered, ethanol (15ml×5) was washed, and vacuum-dried at room temperature (vacuum degree 0.1MPa) for 12 hours. The prepared mercapto-functionalized nanopores [Cu 3 (BTC) 2 ] n Metal-organic frameworks were characterized by powder X-ray diffraction (see figure 1 (d)), its X-ray diffraction and reported nanoporous metal-organic frameworks [Cu 3 (BTC) 2 (H 2 O) 3 ] n It is weaker than that; its BET specific surface area has been determined to be 80m 2 / , pore volume 0.18cm 3 / g, the pore size distribution is determined to be 0.4-0.7nm; its infrared spectrum ( image 3 (c)) proves that there are two kinds of thiol functional groups in the ethanedithiol molecule, namely: the thiol that coordinates with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com