Heteratom doped carbon nano-tube-graphene complex and preparation method thereof

A technology of carbon nanotubes and heteroatoms, applied in the preparation of heteroatom-doped carbon nanotube-graphene composites based on sheet materials, in the field of heteroatom-doped carbon nanotube-graphene composites, can solve the problem of carbon Difficult growth process of nanotubes, structural damage of carbon materials, poor stability, etc., to facilitate engineering scale-up and mass production, improve reactivity, and improve electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

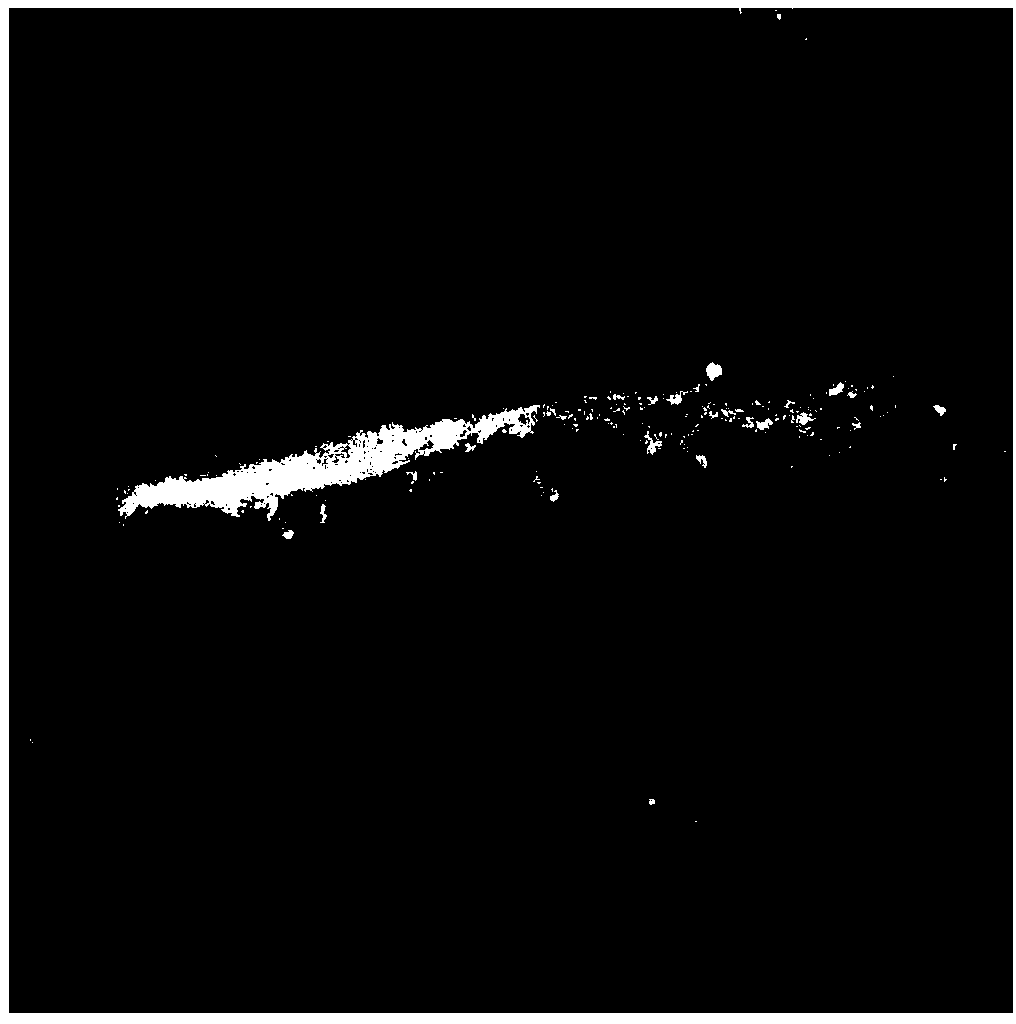

[0030] Example 1: Nitrogen-doped carbon nanotube-graphene composites were prepared through a fixed bed using FeMoMgAl LDH as a catalyst.

[0031]Prepare FeMoMgAl with Fe content of 10 % and Mo content of 0.05 % (where Mg and Al account for 60 % and 29.95 % respectively) LDHs are used as catalysts, and 40 mg is evenly spread in a quartz boat, and placed in a tubular fixed bed reaction inside the device. Nitrogen was used as the carrier gas with a flow rate of 200 sccm. Under this atmosphere, the temperature of the reactor was raised from room temperature to 1000 o C; after that, the reaction temperature was maintained at 1000 o C, the mixed gas of methane / hydrogen / ammonia is fed, and the corresponding flow rates are 100, 50, and 60 sccm respectively, and the chemical vapor deposition process is carried out to simultaneously deposit nitrogen-doped carbon nanotubes and graphene. After 10 min, the carbon source methane, the nitrogen source ammonia and hydrogen were turned off, ...

Embodiment 2

[0032] Example 2: Nitrogen-doped carbon nanotube-graphene composites were prepared through a fixed bed using FeMgAl LDH as a catalyst.

[0033] Prepare FeMgAl LDHs with Fe content of 35% (Mg and Al account for 43% and 22% respectively) as a catalyst, take 40 mg evenly spread in a quartz boat, and place it in a tubular fixed-bed reactor. Argon was used as the carrier gas with a flow rate of 200 sccm. Under this atmosphere, the temperature of the reactor was raised from room temperature to 500 o C, then feed the mixed gas of ethylene / hydrogen / acetonitrile, wherein the partial pressures of carbon source ethylene and nitrogen source acetonitrile are 10% and 5% respectively, and carry out chemical vapor deposition process to deposit nitrogen-doped carbon nanotubes. Close ethylene, acetonitrile and hydrogen after 10min, the reactor temperature is raised to 1000 o C, then feed the mixed gas of carbon source ethane and argon, wherein the partial pressure of carbon source ethane is 2...

Embodiment 3

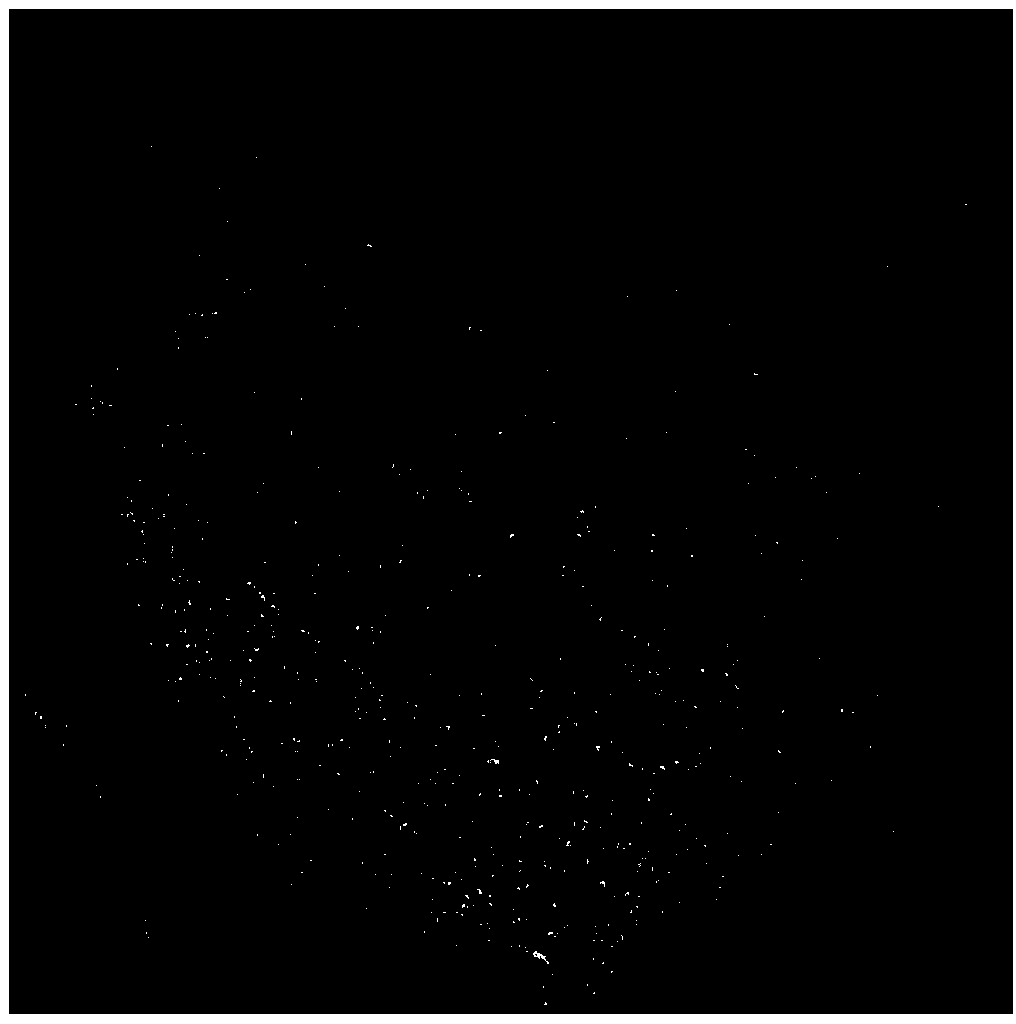

[0034] Example 3: Phosphorus atom-doped carbon nanotube-graphene composite was prepared by using Co / vermiculite as a catalyst through a fluidized bed.

[0035] Co / vermiculite with a Co content of 1% was used as a catalyst, and 1 g was put into a fluidized bed reactor with a diameter of 20 mm. Nitrogen was used as the carrier gas with a flow rate of 600 sccm. Under this atmosphere, the temperature of the reactor was raised from room temperature to 650 o C, after which the reaction temperature was maintained at 650 o C, the mixed gas of carbon source propylene, hydrogen and nitrogen is introduced, wherein the partial pressure of carbon source propylene is 25%, and the process of chemical vapor deposition is carried out to deposit carbon nanotubes. After 20 min, the carbon source propylene was closed, and the reactor temperature was raised to 1200 °C under a nitrogen atmosphere. o C, then pass into the mixed gas of carbon source methane and phosphorus source triphenylphosphine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com