Cordierite material prepared by utilizing rare earth tailing and manufacturing method thereof

A technology for rare earth tailings and a manufacturing method, applied in the field of ceramic materials, can solve problems such as hidden dangers of safety and waste of resources, and achieve the effects of reducing pollution, lowering sintering temperature, and making full use of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

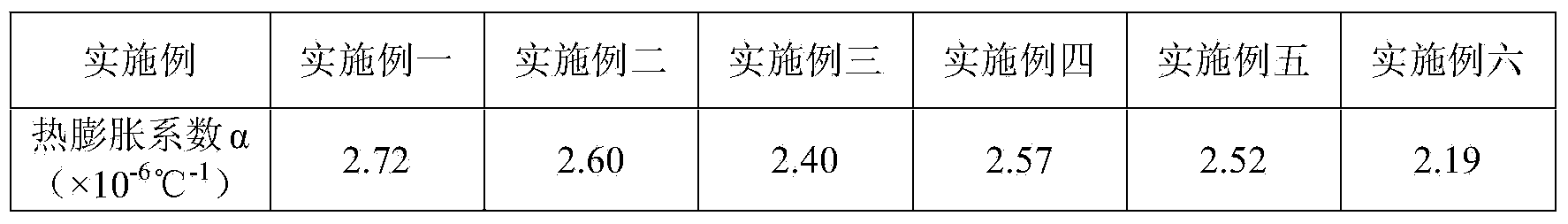

Examples

Embodiment 1

[0023] 1. The cordierite material prepared by using rare earth tailings in this embodiment is composed of 55% rare earth tailings, 14% lightly burned magnesia, and 31% bauxite.

[0024] 2. The preparation method of the cordierite material in this example is as follows:

[0025] (1) adding each material into a ball mill for wet ball milling to obtain a slurry;

[0026] (2) After the slurry passes through a -250 mesh sieve, it is dried and pressed to obtain a green body;

[0027] (3) The green body is fired at a temperature of 1320°C, and the total firing time is 10 hours, of which the high temperature holding time is 30 minutes, and the product is obtained after firing.

Embodiment 2

[0029] 1. The cordierite material prepared by using rare earth tailings in this embodiment is composed of 53% rare earth tailings, 14% lightly burned magnesia, and 33% bauxite.

[0030] 2. The preparation method of the cordierite material in this example is as follows:

[0031] (1) adding each material into a ball mill for wet ball milling to obtain a slurry;

[0032] (2) After the slurry passes through a -250 mesh sieve, it is dried and pressed to obtain a green body;

[0033] (3) The green body is fired at a temperature of 1350°C. The total firing time is 10 hours, and the high temperature holding time is 50 minutes. The product is obtained after firing.

Embodiment 3

[0035] 1. The cordierite material prepared by using rare earth tailings in this embodiment is composed of 45% rare earth tailings, 13% lightly burned magnesia, and 42% bauxite.

[0036] 2. The preparation method of the cordierite material in this example is as follows:

[0037] (1) adding each material into a ball mill for wet ball milling to obtain a slurry;

[0038] (2) After the slurry passes through a -250 mesh sieve, it is dried and pressed to obtain a green body;

[0039] (3) The green body is fired at a temperature of 1320°C, and the total firing time is 11 hours, of which the high temperature holding time is 40 minutes, and the product is obtained after firing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com