Method for preparing large-specific-surface-area mesoporous TiO2 by using SiO2 in biomass

A high specific surface area, biomass technology, applied in the direction of titanium oxide/hydroxide, titanium dioxide, etc., can solve the problems of difficult parameter control and complicated process flow, and achieve the effect of wide source of raw materials, simple process, and expanded production routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

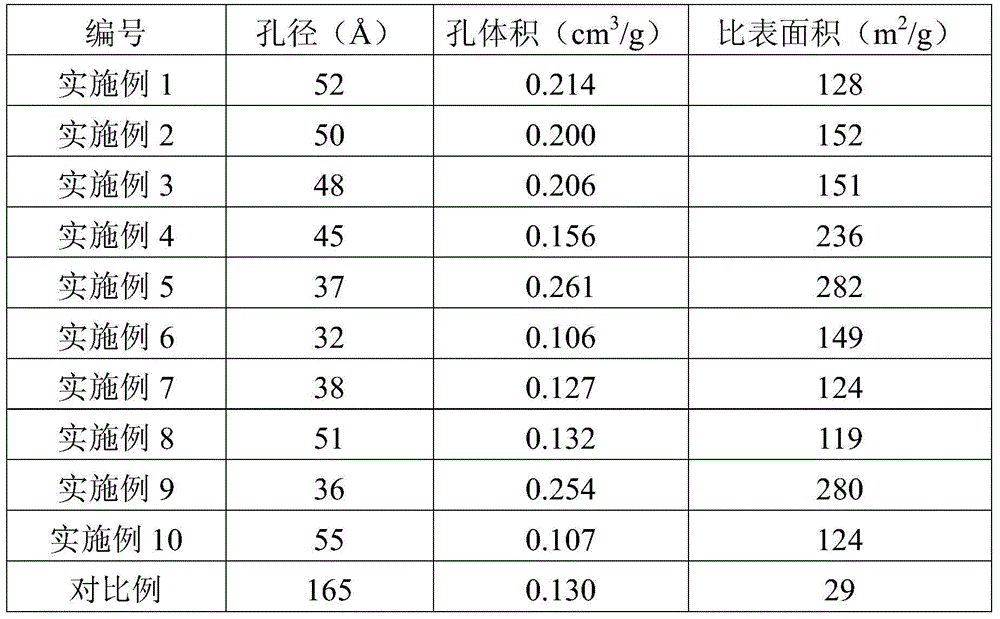

Examples

Embodiment 1

[0031] A kind of utilization of SiO in biomass 2 Preparation of high specific surface area mesoporous TiO 2 method, including the following steps:

[0032] (1) Mesoporous SiO 2 Preparation: Take 10 grams of Northeast rice husk, use 120 grams of 0.2% hydrochloric acid solution in a slightly boiling state (about 100°C) for 2 hours, filter while hot and wash with distilled water until neutral, and dry at 150°C to a constant weight, then placed in a muffle furnace, set the heating rate at 5°C / min, and oxidized and pyrolyzed at a high temperature of 700°C for 2 hours, and cooled naturally to room temperature to obtain mesoporous SiO 2 ;

[0033] (2) Preparation of silicon-titanium composite: take 0.2 gram of mesoporous SiO prepared in step (1) 2 , with 20 grams of 5% sodium hydroxide solution dissolved at 80 ° C for 24 hours; then at 25 ° C, with a mass fraction of 10% TiOSO 4 The solution was titrated to neutrality, filtered after aging for 24 hours, and dried to constant wei...

Embodiment 2

[0037] A kind of utilization of SiO in biomass 2 Preparation of high specific surface area mesoporous TiO 2 method, including the following steps:

[0038] (1) Mesoporous SiO 2Preparation: Take 10 grams of Northeast rice husk, use 120 grams of 0.2% hydrochloric acid solution in a slightly boiling state (about 100°C) for 2 hours, filter while hot and wash with distilled water until neutral, and dry at 150°C to a constant weight, then placed in a muffle furnace, set the heating rate at 5°C / min, and oxidized and pyrolyzed at a high temperature of 700°C for 2 hours, and cooled naturally to room temperature to obtain mesoporous SiO 2 ;

[0039] (2) Preparation of silicon-titanium composite: take 0.2 gram of mesoporous SiO prepared in step (1) 2 , with 10 grams of 10% potassium hydroxide solution at 80°C for 24 hours; then at 25°C, with a mass fraction of 20% TiOSO 4 The solution was titrated to neutrality, filtered after aging for 36 hours, and dried to constant weight at 80°C...

Embodiment 3

[0043] A kind of utilization of SiO in biomass 2 Preparation of high specific surface area mesoporous TiO 2 method, including the following steps:

[0044] (1) Mesoporous SiO 2 Preparation: Take 10 grams of Northeast rice husk, use 120 grams of 0.2% hydrochloric acid solution in a slightly boiling state (about 100°C) for 2 hours, filter while hot and wash with distilled water until neutral, and dry at 150°C to a constant weight, then placed in a muffle furnace, set the heating rate at 5°C / min, and oxidized and pyrolyzed at a high temperature of 700°C for 2 hours, and cooled naturally to room temperature to obtain mesoporous SiO 2 ;

[0045] (2) Preparation of silicon-titanium composite: take 0.5 gram of mesoporous SiO prepared in step (1) 2 , with 10 grams of 10% sodium hydroxide solution dissolved at 80 ° C for 24 hours; then at 25 ° C, with a mass fraction of 20% TiOSO 4 The solution was titrated to neutrality, filtered after aging for 24 hours, and dried to constant we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com