A method for manufacturing oriented silicon steel without glass film and annealing separator

A technology of oriented silicon steel and its manufacturing method, which is applied in the manufacture of oriented silicon steel without glass film, and in the field of annealing separator, can solve problems such as inability to eliminate oxide inclusions, unstable secondary recrystallization, and influence on surface inhibitors, etc., to ensure secondary Effects of recrystallization, guaranteed decarburization efficiency, and improved nitriding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

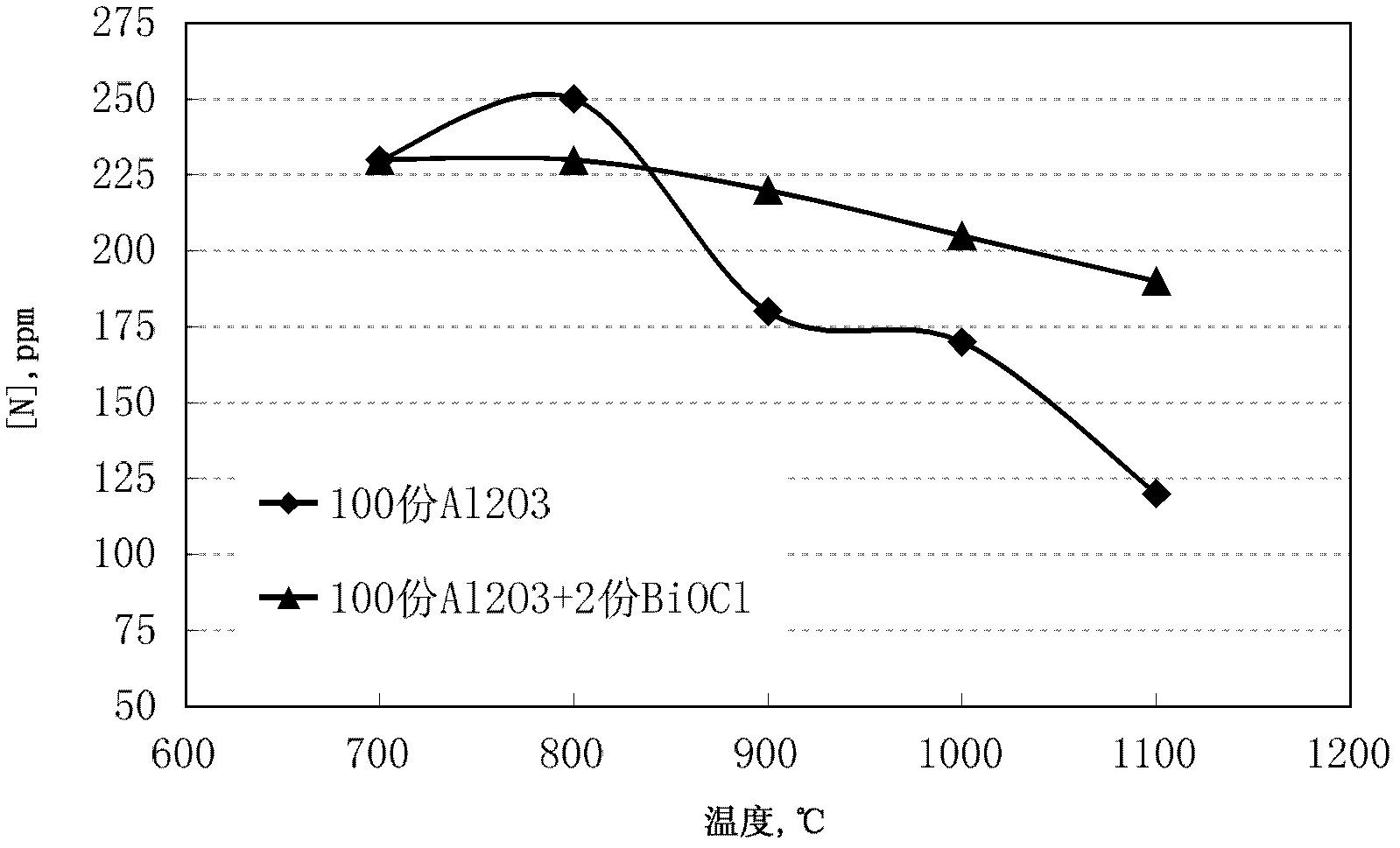

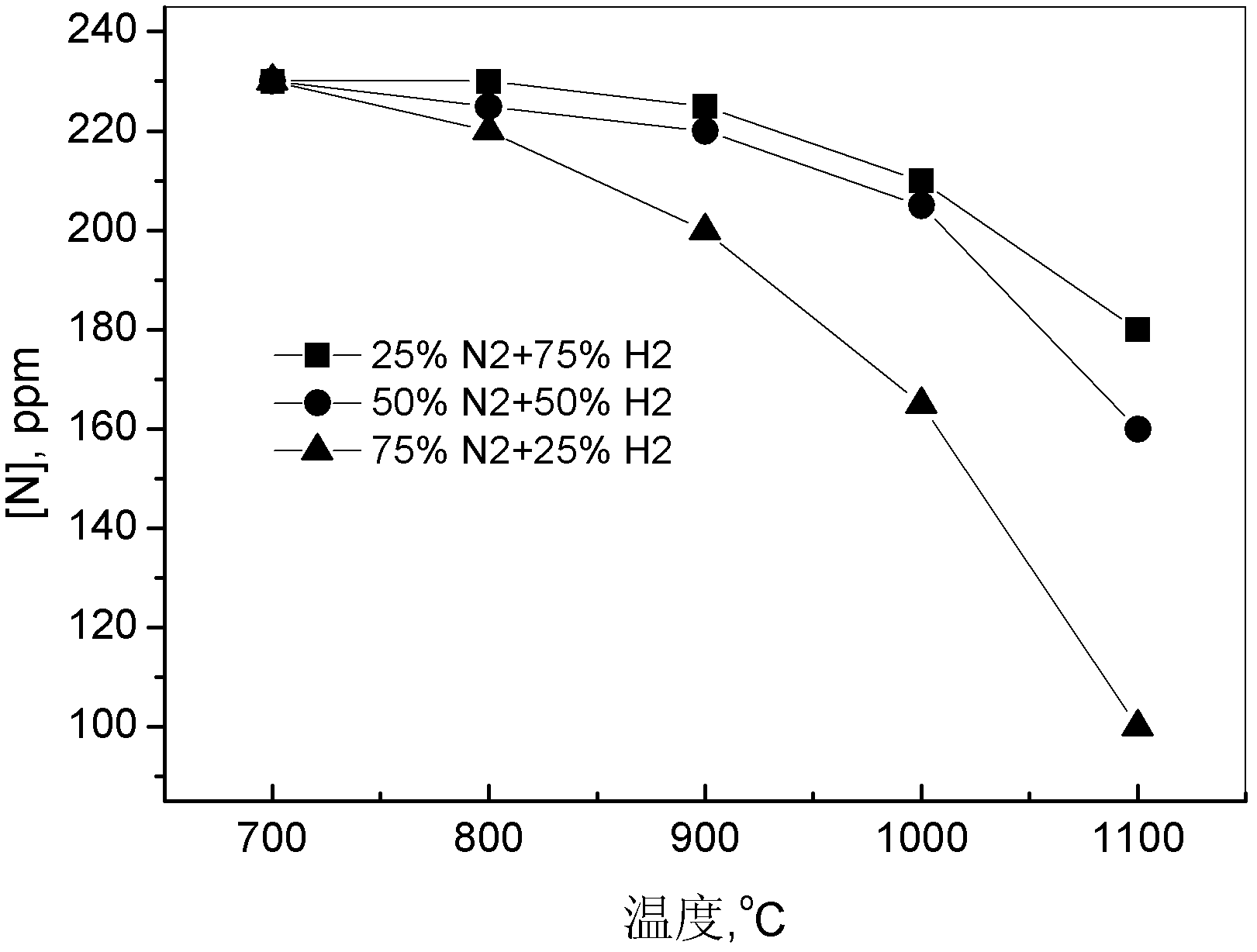

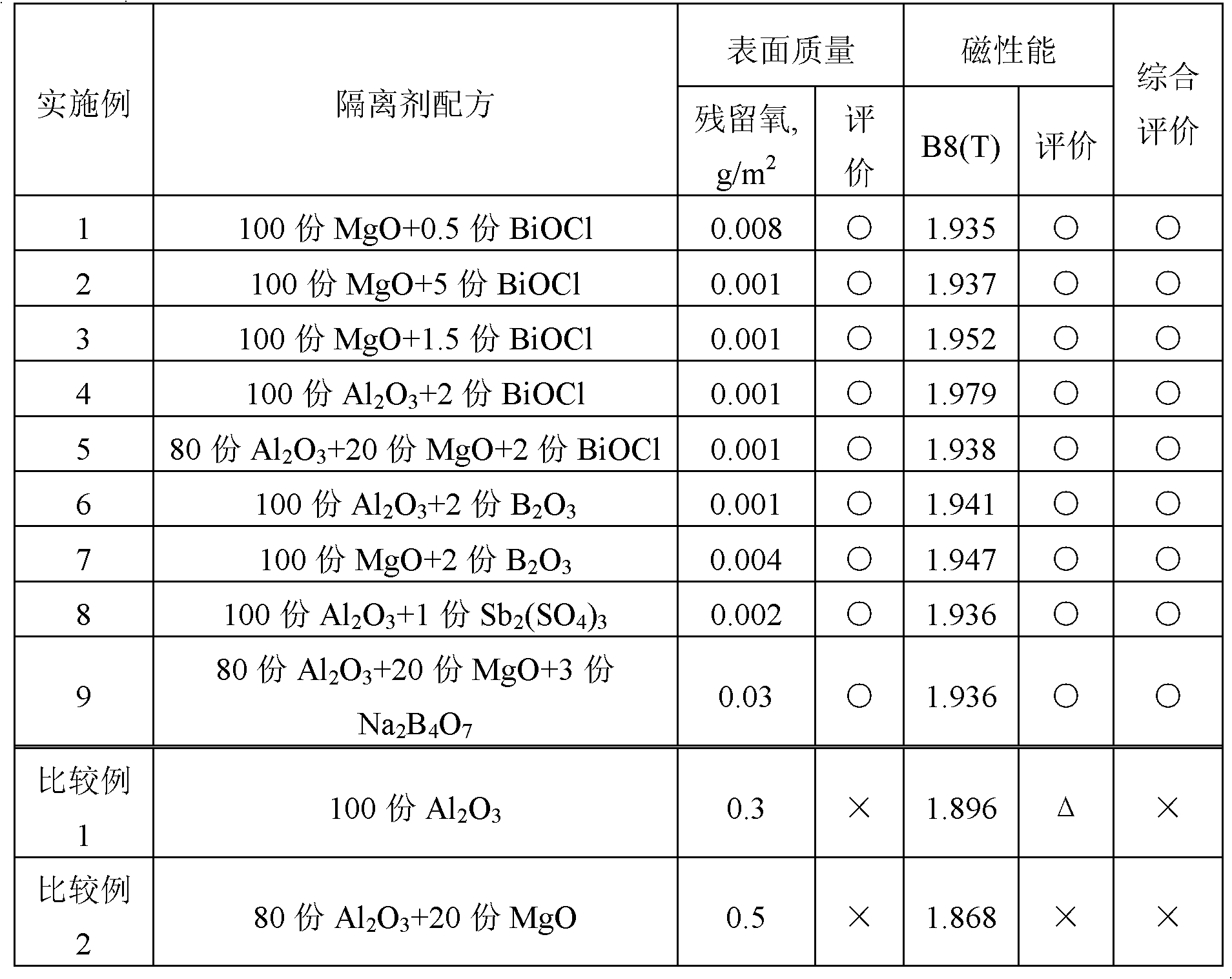

[0050] Steelmaking in a 500kg vacuum furnace, the chemical composition (Wt%) of the slab is: 0.051%C, 3.25%Si, 0.006%S, 0.028%Als, 0.006%N, 0.011%Mn, and the rest is Fe and unavoidable impurities. After the billet is heated at 1150°C, it is hot-rolled into a 2.5mm thick hot-rolled plate. After the hot-rolled sheet is normalized and annealed at 1150°C for 1 minute, it is pickled and cold-rolled to a final sheet thickness of 0.225 mm. The oxidation energy of cold-rolled sheet p(H 2 O) / p(H 2 ) is 0.152 and the temperature is 835 ° C under the conditions of 120 seconds of decarburization annealing treatment; followed by continuous nitriding treatment in a wet ammonia nitrogen hydrogen protection atmosphere. The decarburization annealing plate is coated with annealing release agent, and after being coiled, it is annealed at 1200°C for 20 hours in a dry nitrogen-hydrogen protective atmosphere, and the atmosphere in the heating section is 75% N 2 +25%H 2 , the high insulation sec...

Embodiment 2

[0058] Steelmaking in a 500kg vacuum furnace, the chemical composition (Wt%) of the slab is: 0.051%C, 3.25%Si, 0.006%S, 0.028%Als, 0.006%N, 0.011%Mn, and the rest is Fe and unavoidable impurities. After the billet is heated at 1150°C, it is hot-rolled into a 2.5mm thick hot-rolled plate. After the hot-rolled sheet is normalized and annealed at 1150°C for 1 minute, it is pickled and cold-rolled to a final sheet thickness of 0.225 mm. The cold-rolled sheet is decarburized and annealed at 835°C for 120 seconds; then the nitrogen and hydrogen mixed with wet ammonia pass through the oxidation energy to be nitriding. The coating composition of the decarburized annealed plate is 80 parts Al 2 o 3 +20 parts of MgO+2 parts of BiOCl annealing separator, after coiling, perform high-temperature annealing at 1200°C in a dry nitrogen and hydrogen protective atmosphere and hold for 20 hours. The atmosphere in the heating section is nitrogen-hydrogen mixed gas, and the high holding section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com