Polyimide resin reinforced meta-aramid paper preparation method

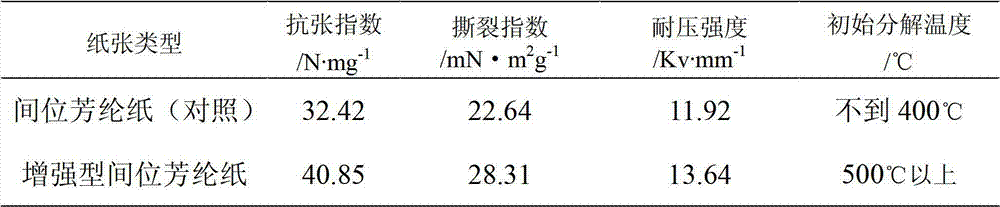

A technology of polyimide resin and aramid paper, which is applied in the fields of paper, papermaking, textiles and papermaking, etc. It can solve the problem that aramid paper has a large difference in strength and performance, cannot meet the requirements of high-end fields, and the research on aramid paper started late and other issues to achieve the effect of strong innovation, increased strength, and promotion of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

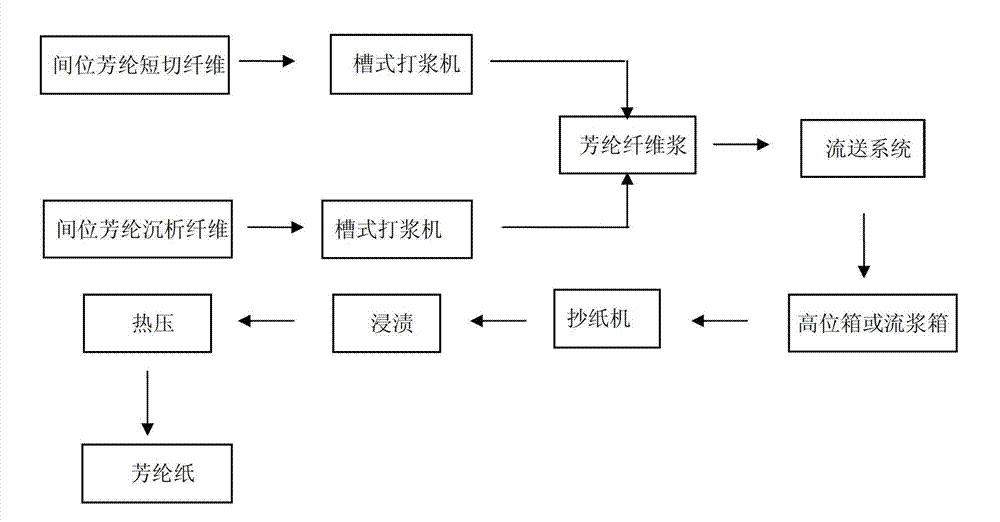

Method used

Image

Examples

Embodiment 1

[0018] The meta-aramid chopped fiber is fully decomposed and dispersed in a trough beater for 30 minutes; the meta-aramid fibrid is decomposed and dispersed in a trough beater until the beating degree is 25°SR to obtain the meta-aramid fiber. In order to reduce the entanglement of meta-aramid fibrids, PEO is added in the amount of 0.01% (relative to the absolute dry mass of meta-aramid fibrids) in the process of dispersing and dispersing. The aramid fibrid fibrid pulp and the meta-aramid chopped fiber after dispersing and dispersing are combined to form an aramid fibrous pulp. The addition amount of the meta-aramid fibrid fibrous pulp is 30%. In terms of dry mass, relative to the absolute dry mass of meta-aramid staple fiber); styrene butadiene latex and CPAM are added to the aramid fiber pulp at 8% (relative to meta-aramid fibrid and inter- The ratio of the sum of the absolute dry mass of the aramid chopped fiber) and 1.5% (relative to the ratio of the sum of the absolute dry ...

Embodiment 2

[0020] The meta-aramid chopped fiber is fully decomposed and dispersed in a trough beater for 10 minutes; the meta-aramid fibrid is decomposed and dispersed in a trough beater until the beating degree is 35°SR to obtain the meta-aramid fiber. In order to reduce the entanglement of meta-aramid fibrids, PEO is added in the amount of 3% (relative to the absolute dry mass of meta-aramid fibrids) in the process of dispersing and dispersing. Aramid fibrid fibrid pulp and the meta-aramid chopped fiber after dispersing and dispersing are combined to form an aramid fiber pulp. The addition amount of the meta-aramid fibrid fibrous pulp is 10% (the meta-aramid fibrid fibrid is used for insulation In terms of dry mass, relative to the absolute dry mass of meta-aramid chopped fiber); styrene butadiene latex and CPAM are added to the aramid fiber pulp at 18% respectively (relative to meta-aramid fibrid and inter- The ratio of the sum of the absolute dry mass of the aramid chopped fiber) and ...

Embodiment 3

[0022] The meta-aramid chopped fiber is fully decomposed and dispersed in a trough beater for 60 minutes; the meta-aramid fibrid is decomposed and dispersed in a trough beater to a beating degree of 60°SR to obtain a meta-aramid fiber. To reduce the entanglement of meta-aramid fibrids, PEO is added in the amount of 8% (relative to the absolute dry mass of meta-aramid fibrids) during the process of dispersing and dispersing; Aramid fibrid fibrous pulp and the meta-aramid chopped fiber after dispersing and dispersing are combined to form an aramid fibrous pulp. The addition amount of meta-aramid fibrid fibrous pulp is 0.01%. In terms of dry mass, relative to the absolute dry mass of meta-aramid chopped fiber); styrene butadiene latex and CPAM are added to the aramid fiber pulp at 0.1% (relative to meta-aramid fibrid and inter- The ratio of the sum of the absolute dry mass of the aramid chopped fiber) and 20% (the ratio of the sum of the absolute dry mass of the meta-aramid fibrid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com