Light-emitting diode (LED) line lamp and implementation method thereof

A realization method and technology of LED lamp beads, applied in lighting and heating equipment, instruments, display devices, etc., can solve the problems of unstable LED neon lights and soft lights, cumbersome installation, high energy consumption, etc., and achieve flexible pattern design and easy processing The process is simple and the effect of overcoming energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

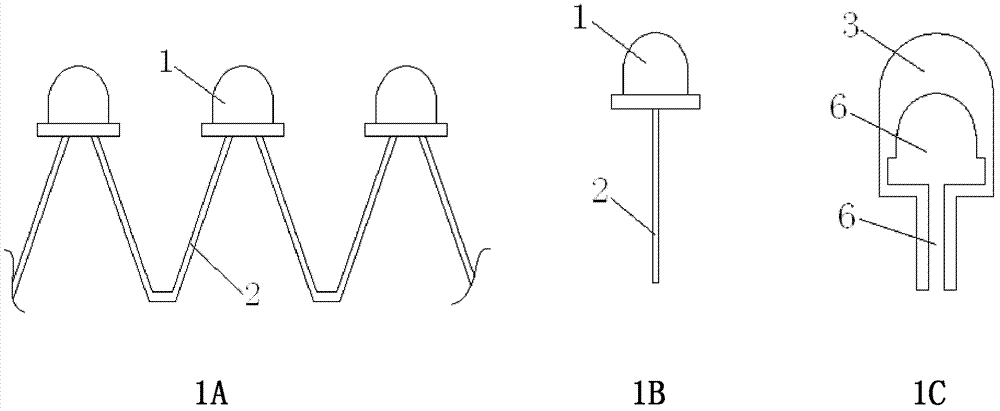

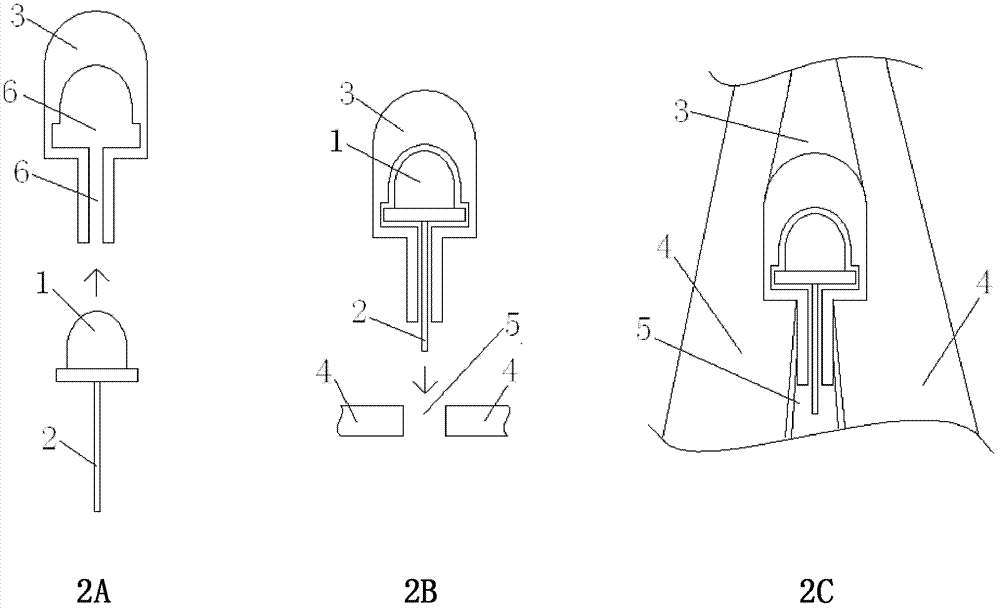

[0063] Such as figure 1 and figure 2 As shown, first cut out a transparent groove (5) that is consistent with the design pattern and has a suitable width on the plate-shaped base (4) according to the designed light line pattern. The width of the transparent groove (5) can be It is advisable to tightly clamp and fix the outside of the clamping groove (6) on the back of the (1) flexible light-diffusing strip (3) that has been embedded in the LED lamp bead string. In order to maintain the integrity of the plate-shaped base (4) after cutting, the transparent groove forming a closed loop on the plate-shaped base can be cut into discontinuous grooves (5), so as to ensure that the base part within the closed loop does not Separated from the entire base (4), the discontinuous part between such grooves can be covered with a flexible astigmatism strip (3), ensuring the integrity of the light strip. The flexible astigmatism strip (3) is a strip made of soft and translucent material wi...

Embodiment 2

[0065] Such as image 3 and Figure 4 As shown, the inside of the clamping groove (6) of the flexible astigmatism strip (3) can be processed into two structures with several small pits arranged at a certain distance and without small pits. The structure with small pits can make the LED lamp bead Each LED lamp bead in the string (1) can be wrapped and fixed by the clamping groove (6) more firmly; the structure without a small pit can make each LED lamp bead in the LED lamp bead string (1) more flexible Embedded in the clip groove (6) without having to consider the constraints of fixed spacing. Refer to the method described in Example 1 for the implementation method of using the flexible astigmatism strip (3) of these two structures to form an LED line lamp.

Embodiment 3

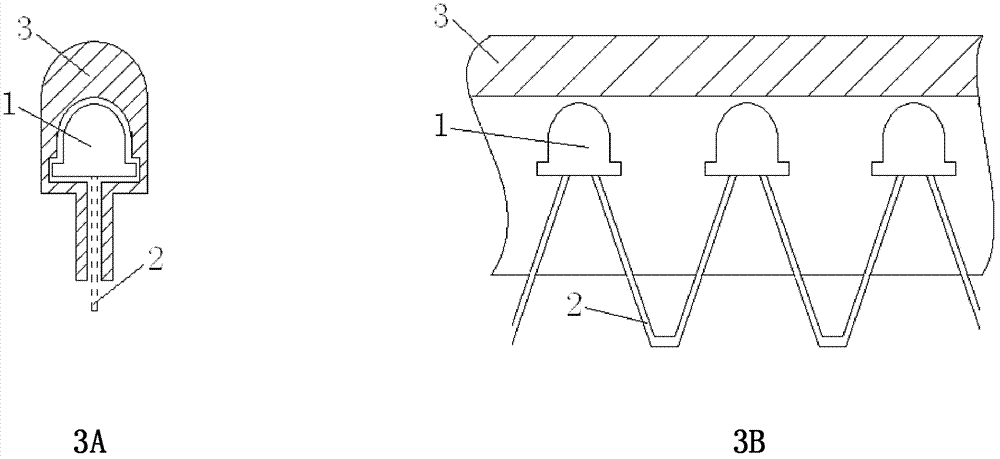

[0067] Such as Figure 5 and Figure 6 As shown, the flexible astigmatism strip (3) can be made into a hollow structure, and the interior of the clamping groove (6) can also be made into two structures with a number of small pits arranged at a certain distance and without small pits. The hollow structure can be Saving materials can also get better astigmatism effect. Refer to the method described in Embodiment 1 and Embodiment 2 for the implementation method of using the flexible astigmatism strip (3) with a hollow structure to form an LED line lamp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com