Method for quantitatively examining center segregations of wire rod

An inspection method and center positioning technology, applied in the direction of measuring devices, analyzing materials, and using wave/particle radiation for material analysis, etc., can solve the problems of shallowness and inability to quantitatively evaluate, so as to improve accuracy, improve the level of analysis and detection, and save energy. Analyzing the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with specific embodiment the present invention is further described:

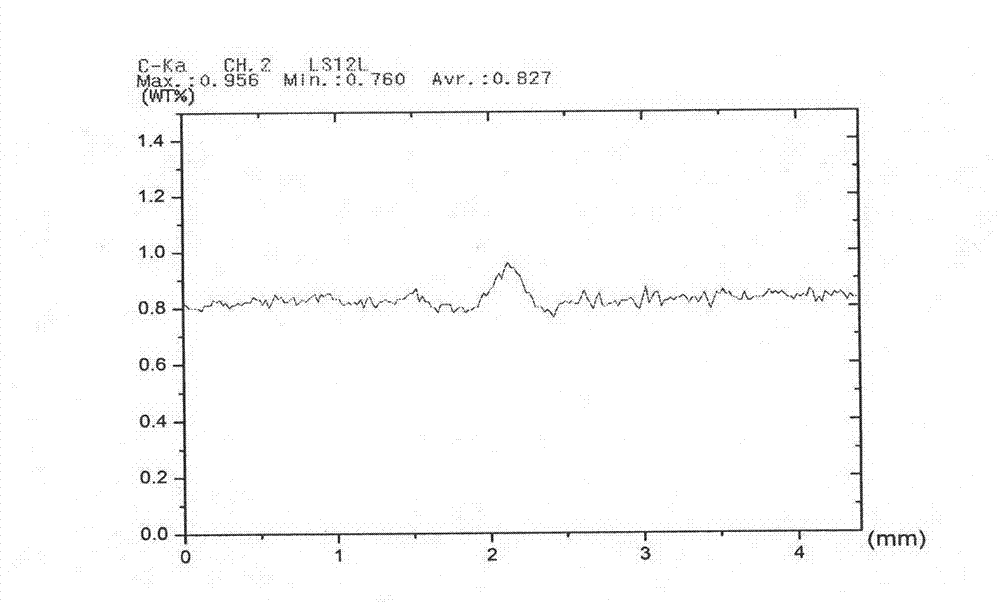

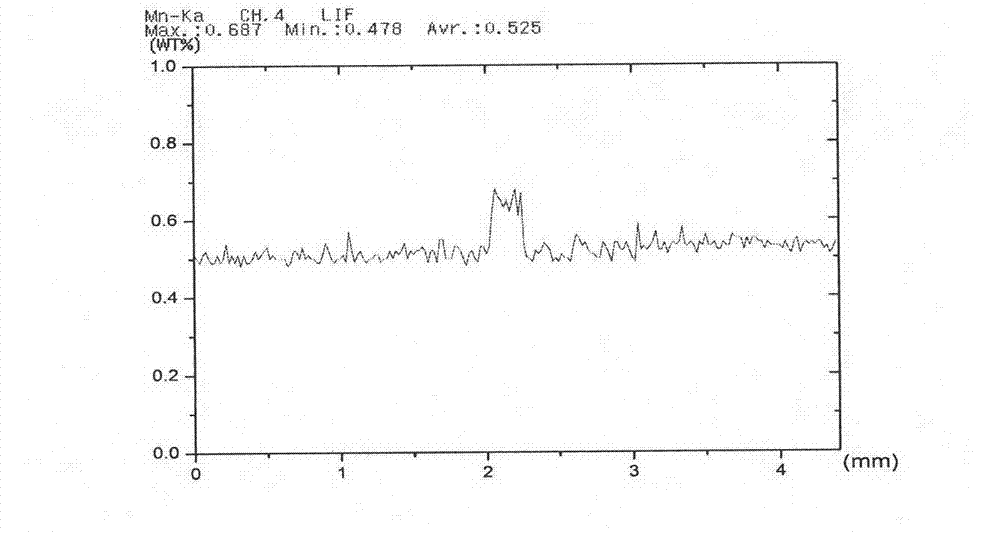

[0013] Apply the wire rod center segregation evaluation method of the present invention to evaluate the LX80A cord steel wire rod with a diameter of 5.5mm, and its composition is as follows: C: 0.82%, Si: 0.19%, Mn: 0.52%, P: 0.0068%, S: 0.0072 %, O: 14%, Ni: 0.0055%, Als: <0.0005%, Cr: 0.021%, N: 0.0027%, and the balance is Fe and unavoidable impurities.

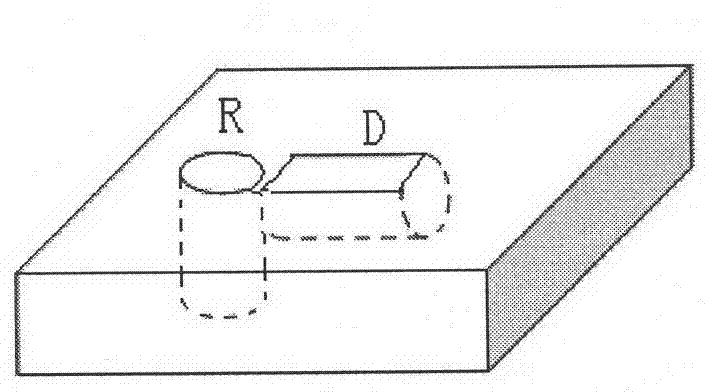

[0014] 1) Center positioning: Take two 10mm long wire rod samples. Grind the cross-section of one wire rod sample flat, cut the other sample along the longitudinal 2 / 3 of the wire rod, and grind the section of the larger sample flat. Place the above two flattened planes next to each other on the same plane and inlay them with conductive resin such as figure 1 shown. Grind the sample and pay attention to observation. When the width of the longitudinal section is equal to the diameter of another wire rod, polish the plane, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com