Two-phase multipolar switch reluctance motor

A reluctance motor, multi-pole switch technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of lack of self-starting ability, affecting the use range of the motor, low motor performance, etc., to achieve simple structure, improve performance, The effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further illustrate the present invention, the two-phase multi-pole switched reluctance motor of the present invention will be described in more detail below in conjunction with the embodiments.

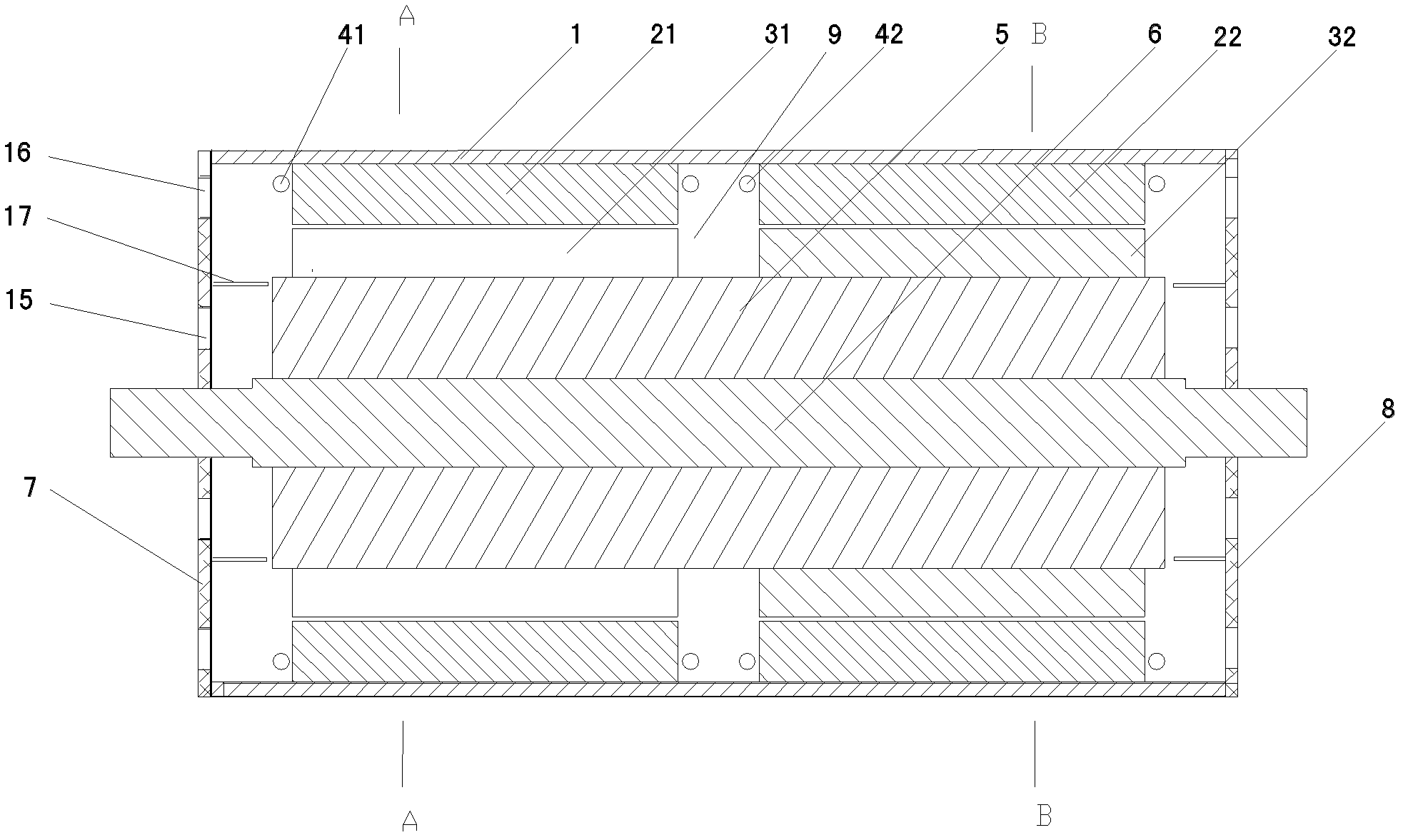

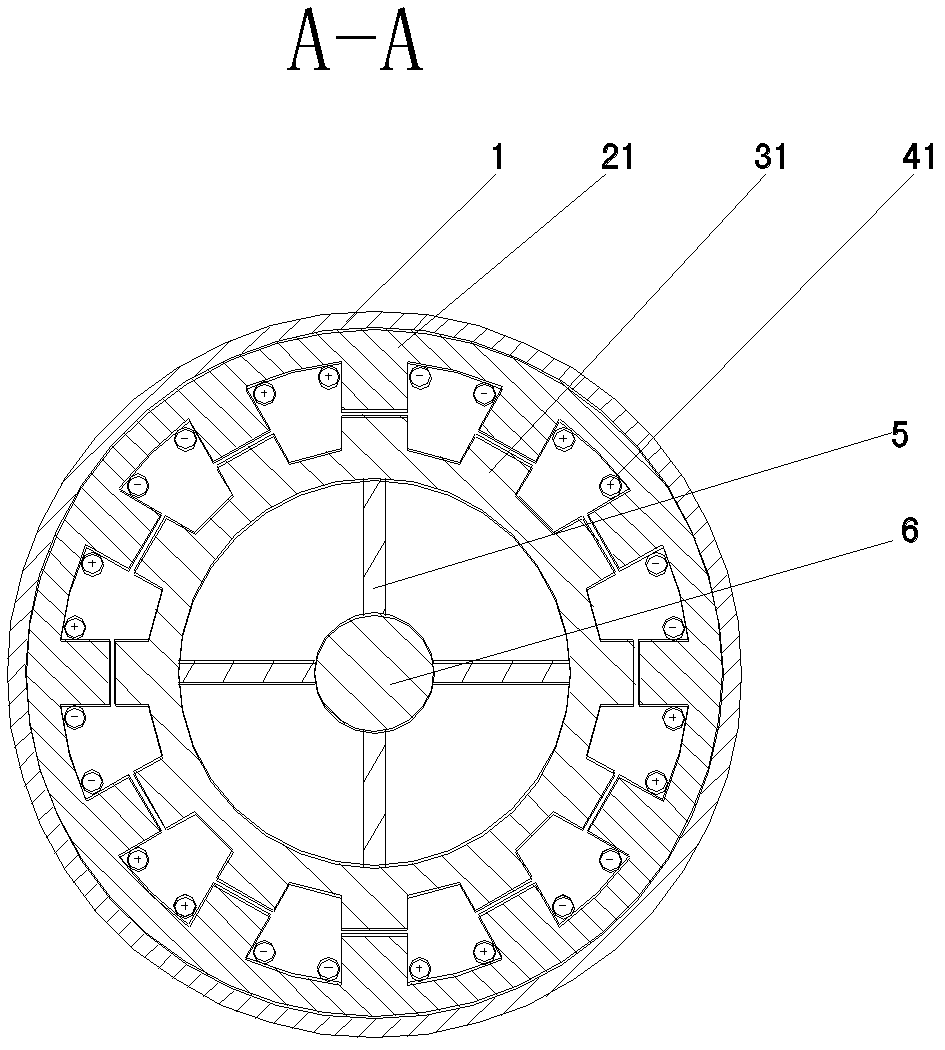

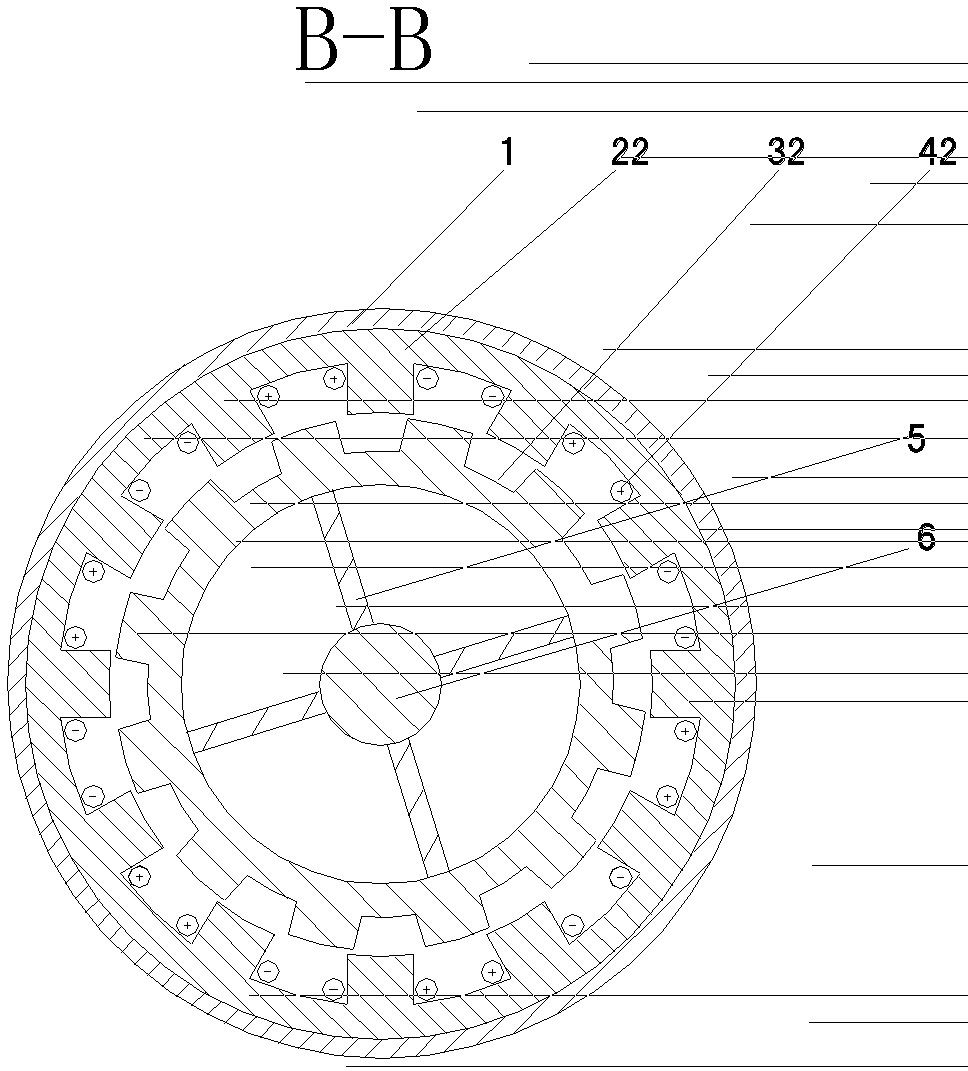

[0025] see Figure 1 to Figure 3 , The two-phase multi-pole switched reluctance motor of the present invention includes a casing 1, a left end cover 7 and a right end cover 8, as well as a stator, a rotor, rotor spoke iron 5 and a rotating shaft 6.

[0026] The stator includes stator poles and excitation coils, and the rotor includes rotor poles and rotor spokes 5 . The double-salient pole structure with the same number of stator poles and rotor poles is made of laminated electrical steel sheets.

[0027] The stator poles and excitation coils are fixed inside the housing 1 , and the rotor poles are set on the rotating shaft 6 through the rotor spokes 5 . The excitation coils of two adjacent magnetic poles are sequentially connected one forward and one reverse, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com