Preparation method of lactic acid bacteria liquid for animal cultivation

A technology of lactic acid bacteria liquid and animal breeding, applied in animal feed, animal feed, application, etc., can solve the problems of difficult promotion and application of lactic acid bacteria preparations, high requirements for aseptic conditions, and large investment in equipment, so as to improve feed conversion efficiency and increase The effect of average daily gain and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

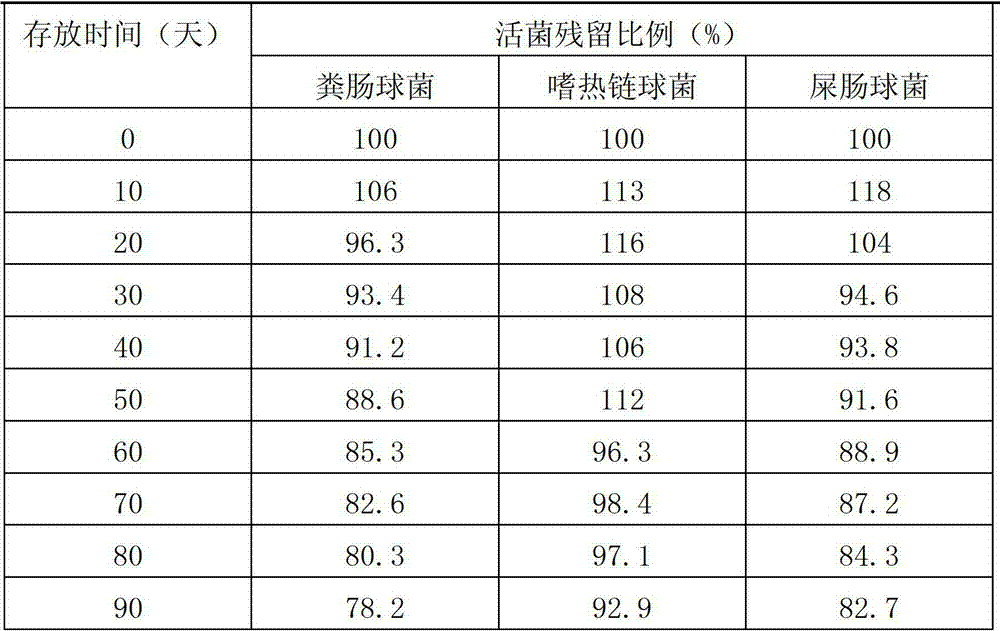

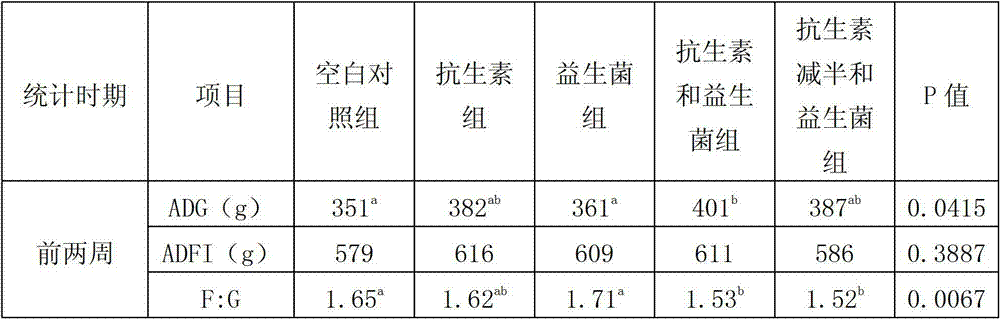

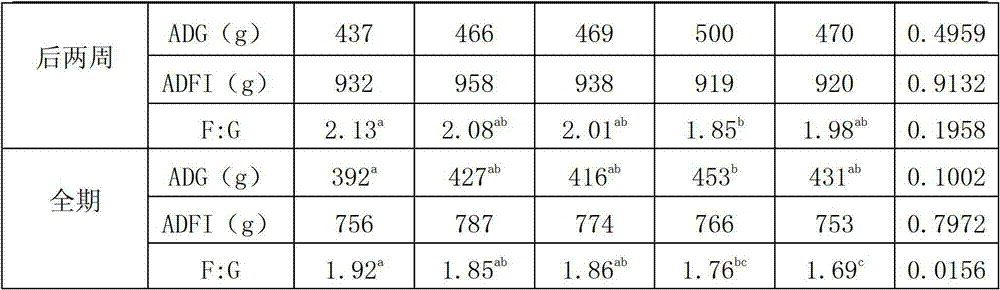

[0029] Example 1, Preparation of Enterococcus faecalis Liquid for Animal Breeding

[0030] Option I

[0031] Take 35kg of peeled soybean meal, add 350kg of water, soak at room temperature (15-35°C) for 20 hours, grind it with a refiner (into a powder), centrifuge to remove the precipitate, take all the water extract (that is, the supernatant) with a pump The water pump is transferred into a water tank with a capacity of 1000 liters; add 50kg of water, 20kg of glucose and 20kg of sugar beet molasses, and stir at a low speed of 30 to 36rpm; heat the steam to 95°C for 20 minutes; pass the cooling water in the jacket to cool down, At the same time, stir at a low speed of 12-15rpm to keep the temperature of the medium even; when the temperature of the solution in the tank drops below 38°C, insert 8 liters of Enterococcus faecalis seed solution (that is, the volume ratio is 1:50 for inoculation) ), let it stand for 5 minutes, and then divide it into plastic buckets with a volume of...

Embodiment 2

[0050] Example 2, Preparation of Streptococcus thermophilus Liquid for Animal Breeding

[0051] Option I

[0052] Take 35kg of peeled soybean meal, add 350kg of water, soak at room temperature (15-35°C) for 25 hours, grind it with a refiner (into powder), centrifuge to remove the precipitate, and take all the water extract (that is, the supernatant) with a pump The water pump is transferred into a water tank with a volume of 1000 liters; add 50kg of water, 20kg of brown sugar and 20kg of beet molasses, and stir at a low speed of 30 to 36rpm; heat the steam to 100°C for 5 minutes; pass the cooling water in the jacket to cool down, At the same time, stir at a low speed of 12 to 15 rpm to keep the temperature of the medium even; when the temperature of the solution in the tank drops below 38°C, add 200 liters of Streptococcus thermophilus seed solution (that is, the volume ratio is 1:2 Inoculation), let stand for 5 minutes, and then divide into plastic buckets with a volume of 1...

Embodiment 3

[0056] Example 3, Preparation of Enterococcus faecom Liquid for Animal Breeding

[0057] Option I

[0058] Take 35kg of peeled soybean meal, add 350kg of water, soak at room temperature (15-35°C) for 30 hours, grind it with a refiner (into a powder), centrifuge to remove the precipitate, and take all the water extract (that is, the supernatant) with a pump The water pump is transferred into a water tank with a volume of 1000 liters; add 50kg of water, 20kg of glucose and 20kg of beet molasses, stir at a low speed of 30-36rpm; heat to 95-100°C for 10 minutes with steam; pass cooling water through the jacket Cool down, and at the same time stir at a low speed of 12-15rpm to keep the temperature of the culture medium uniform; when the temperature of the solution in the tank drops below 38°C, add 20 liters of Enterococcus faecom seed solution (that is, the volume ratio is 1: 20 inoculations), let it stand for 5 minutes, and then divide it into plastic buckets with a volume of 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com