Burley tobacco flavor enhancing preparation and application of burley tobacco flavor enhancing preparation

A technology for burley tobacco and preparation, which is applied in the application, tobacco, tobacco processing and other directions, can solve the problems of poor coordination, high irritation, and poor aftertaste of burley smoke, and achieves a low cost, improved fineness, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Using Hubei Burley Tobacco Variety Eyan No. 2 as Material

[0018] (1) Reagent preparation: Dissolve glucose, ascorbic acid and neutral protease in water and stir evenly to prepare a burley flavoring preparation containing 100 g of glucose, 10 g of ascorbic acid and 6 g of neutral protease per 1000 g of the solution;

[0019] (2) Wait until the lower leaves of Burley tobacco turn yellow by 70%, the leaf color turns from green to yellow, and the yellow is green, the main vein is white and bright, and the sides of the branch veins and small veins are slightly green. In the morning on a sunny day, spray the preparation prepared in step (1), spray 10 liters of the aqueous solution per acre, and evenly spray on both sides of the leaves, with water droplets dripping from the leaves as the standard. After 2 days, harvest and adjust.

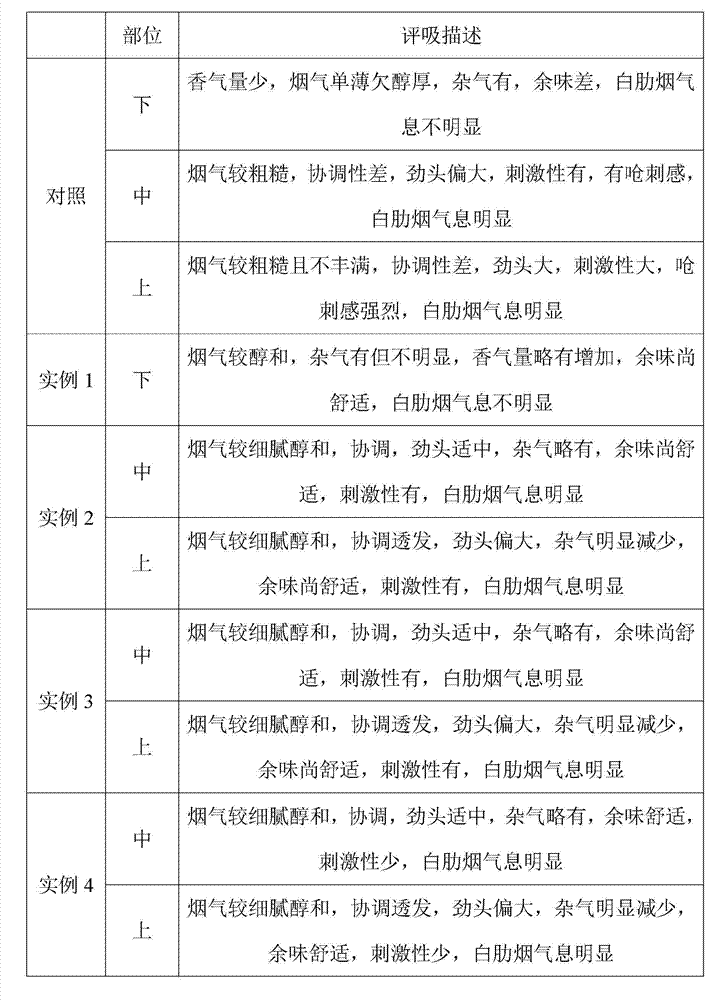

[0020] After the Burley tobacco leaves harvested in this example are prepared into cigarettes, the smoking effects are shown in Table 1.

Embodiment 2

[0022] Using Hubei Burley Tobacco Variety Eyan No. 2 as Material

[0023] (1) Reagent preparation: Dissolve sucrose, citric acid and neutral protease in water and stir evenly to prepare a burley flavoring preparation containing 150 g of sucrose, 15 g of citric acid and 12 g of neutral protease per 1000 g of the solution;

[0024] (2) After the lower leaves of Burley tobacco are harvested, and the leaves of the upper two sheds are mature, mature spots appear on the top leaves, the main veins are bright, the hairs fall off, and the leaf surface turns yellow by more than 90%. In the morning on a sunny day, spray the preparation prepared in step (1), spray 15 liters of the water solution per mu, and evenly spray on both sides of the leaves, with water droplets dripping from the leaves as the standard. After 5 days, the half-whole plant is cut and harvested, and the cut tobacco plants are evenly placed on the furrows of the tobacco field to let the leaves wither, and then transport...

example 3

[0027] Using Hubei Burley Tobacco Variety Eyan No. 2 as Material

[0028] (1) Reagent preparation: Dissolve sucrose, glucose, citric acid, oxalic acid and neutral protease in water, and stir evenly to obtain 100g sucrose, 20g glucose, 5g citric acid, 7g oxalic acid and 10g neutral protease per 1000g solution Burley flavoring preparations;

[0029] (2) After the lower leaves of Burley tobacco are harvested, and the leaves of the upper two sheds are mature, mature spots appear on the top leaves, the main veins are bright, the hairs fall off, and the leaf surface turns yellow by more than 90%. In the morning on a sunny day, spray the preparation prepared in step (1), spray 12 liters of the aqueous solution per mu, and evenly spray on both sides of the leaves, with water droplets dripping from the leaves as the standard. After 5 days, the half-whole plant is cut and harvested, and the cut tobacco plants are evenly placed on the furrows of the tobacco field to let the leaves withe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com