Gear shaping machine for machining oblique tooth through outer oblique tooth gear follow-up guide method

A technology of external helical gears and gear shaping machines, which is applied to gear teeth manufacturing devices, metal processing machinery parts, gear cutting machines, etc., can solve problems such as inability to process straight teeth or racks, difficulties in design and manufacture, and single processing parameters. Achieve the effects of saving money and time, facilitating structural design, and expanding the value range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

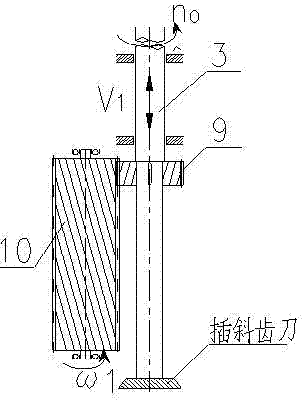

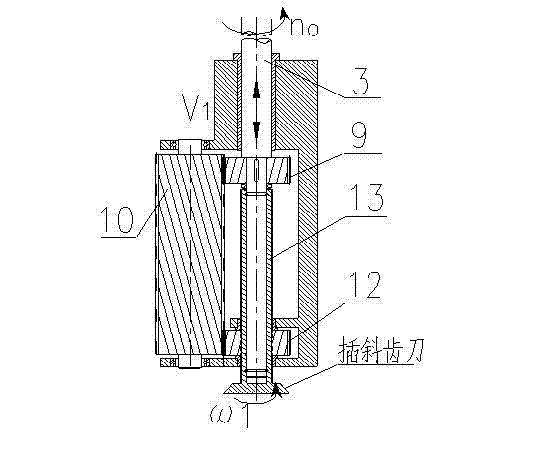

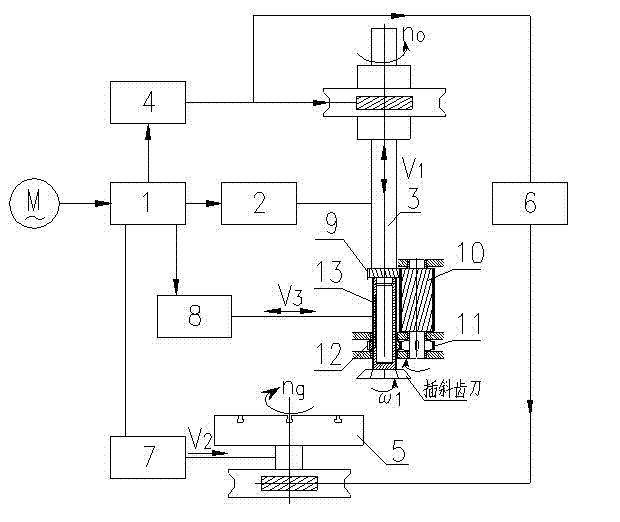

[0038] The invention discloses a technical method for processing helical gears by using the "external helical gear follow-up guide method" to realize the additional rotation of the gear shaper cutter; at the same time, it discloses an "external helical gear follow-up guide additional rotation mechanism" designed according to the method ', according to a preferred embodiment of the present invention, the mechanism is mainly composed of: (see attached image 3 ) The guide external helical gear 9, the follower long external helical gear 10, the additional rotation output gear 11, the cutter bar rotation driving gear 12, the helical gear inserting tool bar 13, the gear shaping machine main shaft 3, and the seat under the meshing state of two parallel shaft systems Body 15 composition, its main structural features are:

[0039] 1. On the main shaft 3 of the gear shaping machine, a guide helical gear 9 with a helix angle of -β is designed and installed, and the two are connected by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com