Low-carbon high-copper high-strength welding wire for gas protection welding

A gas protection, high-strength technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of poor crack resistance of high-strength steel weld metal, reduce the carbon equivalent of weld metal, etc., to improve the resistance Cold cracking performance, effect of welding arc concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment this patent is further explained and illustrated.

[0014] Within the composition range of the low-carbon, high-copper-content, and high-strength gas-shielded welding wire of the present invention, a total of 5 furnaces of welding wire were smelted, and the composition of the welding wire is shown in Table 1. After the welding wire is welded by MIG, the mechanical properties of the deposited metal are shown in Table 2. The deposited metal structure of the welding wire is a mixed structure of acicular ferrite and bainite, and the structure contains a small amount of dispersed retained austenite.

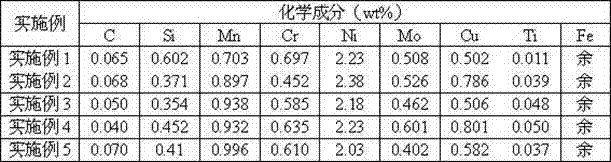

[0015] Table 1 Chemical composition of welding wire

[0016]

[0017] Table 2 Mechanical properties of deposited metal

[0018] Example Rp 0.2 , MPa Rm, MPa A,% Z,% -50℃ KV 2 , J Example 1 805 855 19 60.5 75,80,80 / 78 Example 2 815 850 18.5 64.5 82,58,56 / 65 Example 3 815 860 16.5 64.5 92,9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com