Preparation method of back-sealing vacuum insulation panel

The technology of a vacuum insulation panel and a manufacturing method, which are applied in chemical instruments and methods, heat exchange equipment, and pipelines through thermal insulation protection, etc., can solve the problems of reducing the overall thermal insulation performance of the vacuum thermal insulation panel, and achieve light weight and thermal insulation performance. High, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

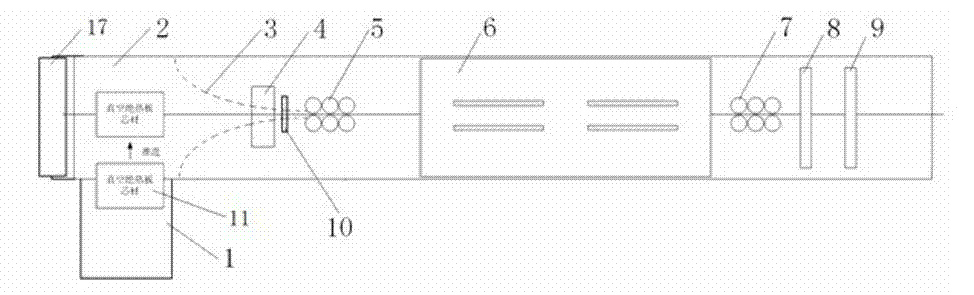

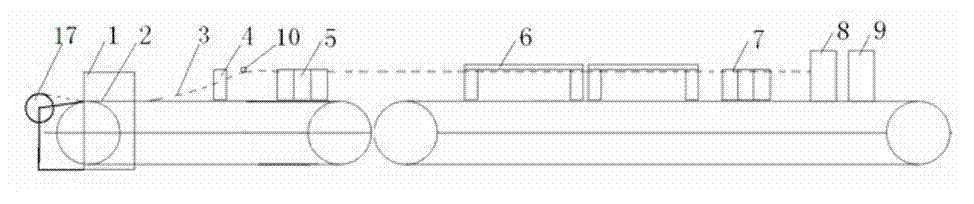

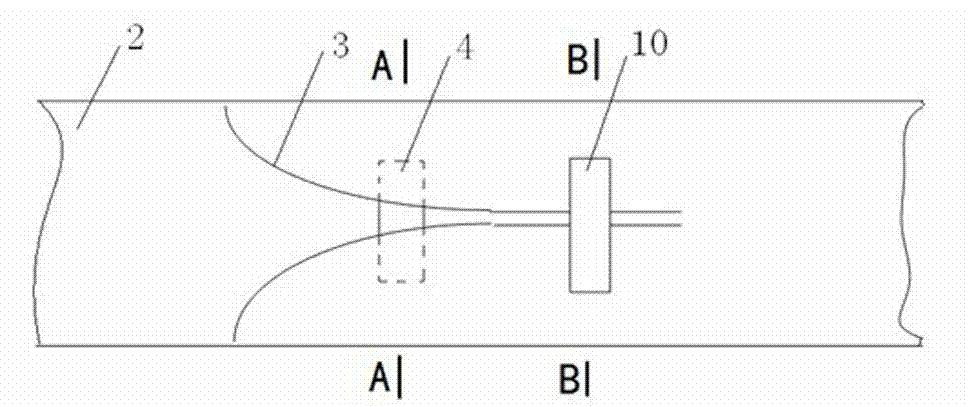

[0011] The invention discloses a method for making a back-sealed vacuum insulation panel. The vacuum insulation panel includes a core material and a gas barrier film coated on the outside of the core material, and the inside is vacuumized. The feature is that:

[0012] (1) The formula of the core material: its composition and parts by weight are: take dry ultrafine silica powder 40-70, filler 0-40, inorganic core material (silica fume, aluminum silicate, perlite- Mixture of two or more kinds) 0-50, inorganic fiber 1-18, getter 0-3, vacuum stabilizer 0-2.8, mix these raw materials evenly;

[0013] (2) Use a bag making machine to make a non-woven bag of a specified size, seal three sides, and leave one side unsealed;

[0014] (3) Weighing and bagging: the core material is weighed according to the formula and poured into the non-woven bag, and the unsealed side of the non-woven bag is sealed;

[0015] (4) Lay the non-woven bag on the leveling machine in the forward direction, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com