Longitudinal connection method for steel-concrete combined beam and existing reinforced concrete T beam

A reinforced concrete and composite beam technology, which is applied in bridges, bridge maintenance, bridge reinforcement, etc., can solve problems restricting the application of steel-concrete composite beams, complex structure and construction, etc., and achieve light lifting weight, fast installation speed, and realization of bending Effects of Moment and Shear Transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

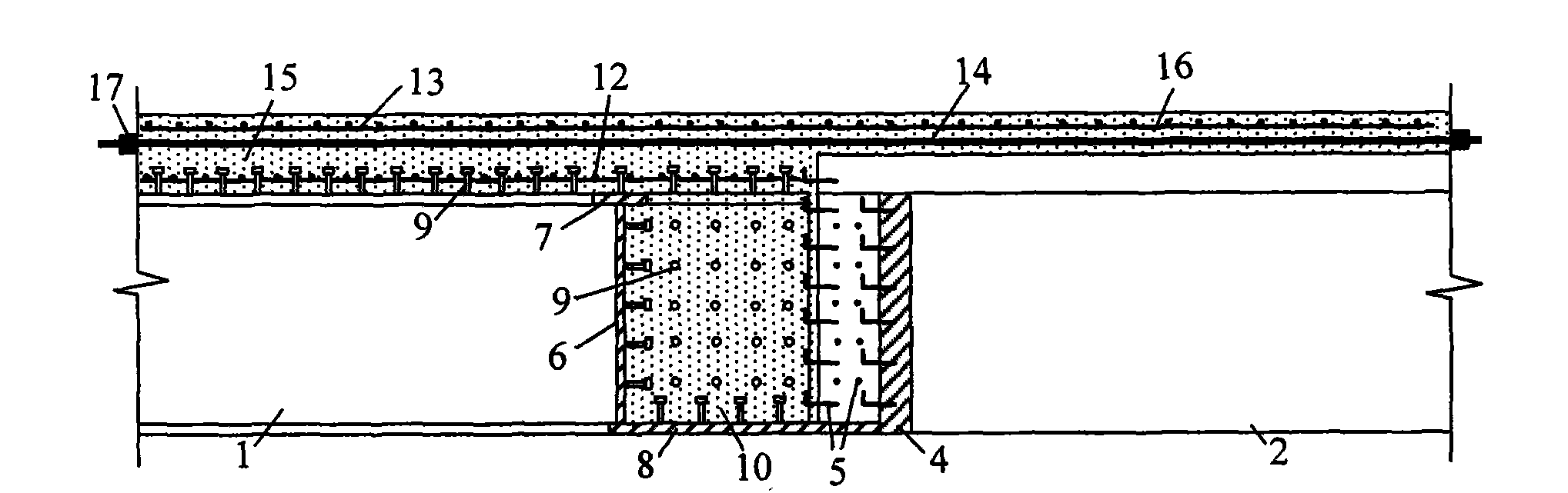

[0027] The structure, processing and use of the present invention will be further described below in conjunction with the accompanying drawings.

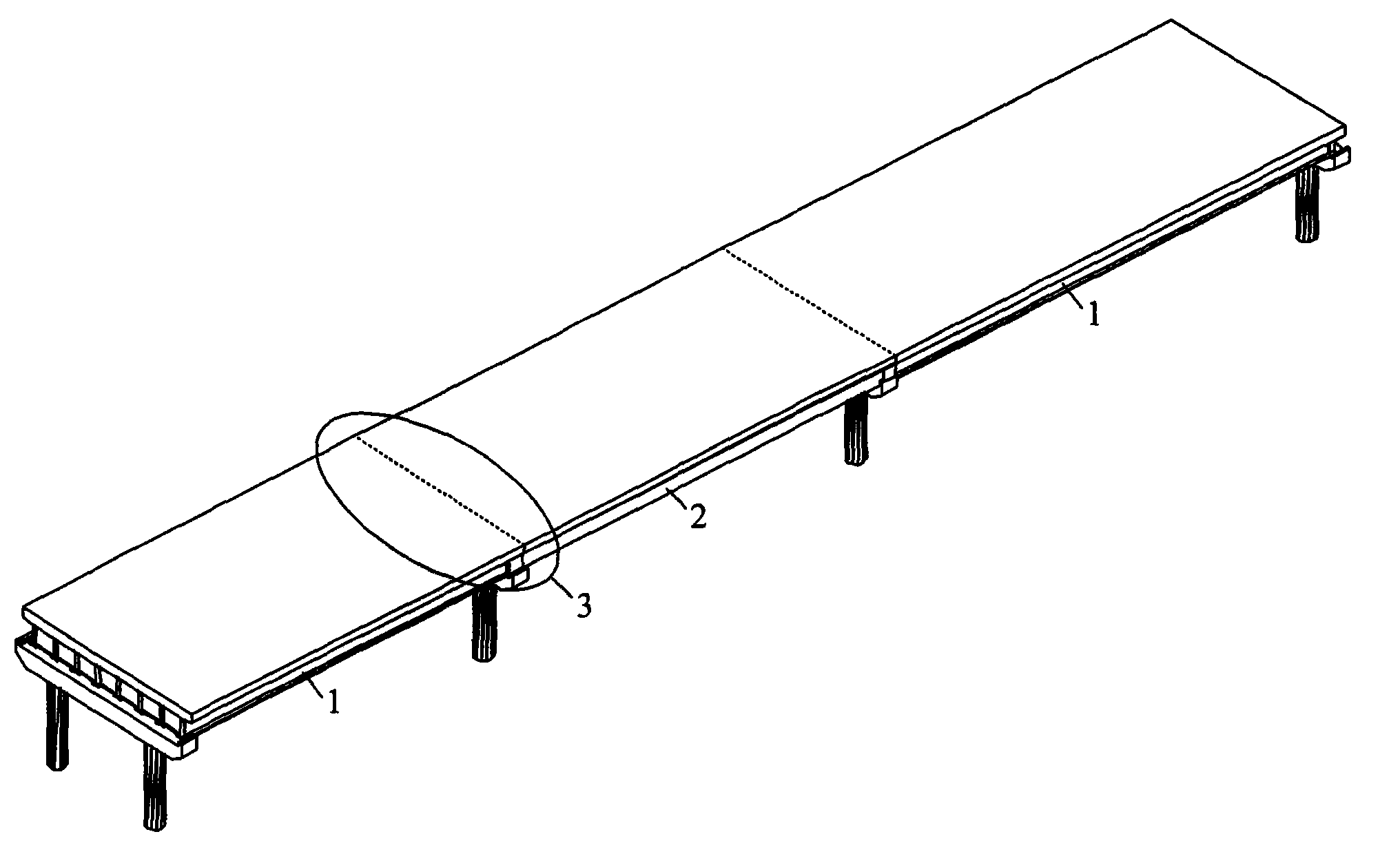

[0028] figure 2 Shown is the overall schematic diagram of the present invention. The specific construction steps are as follows:

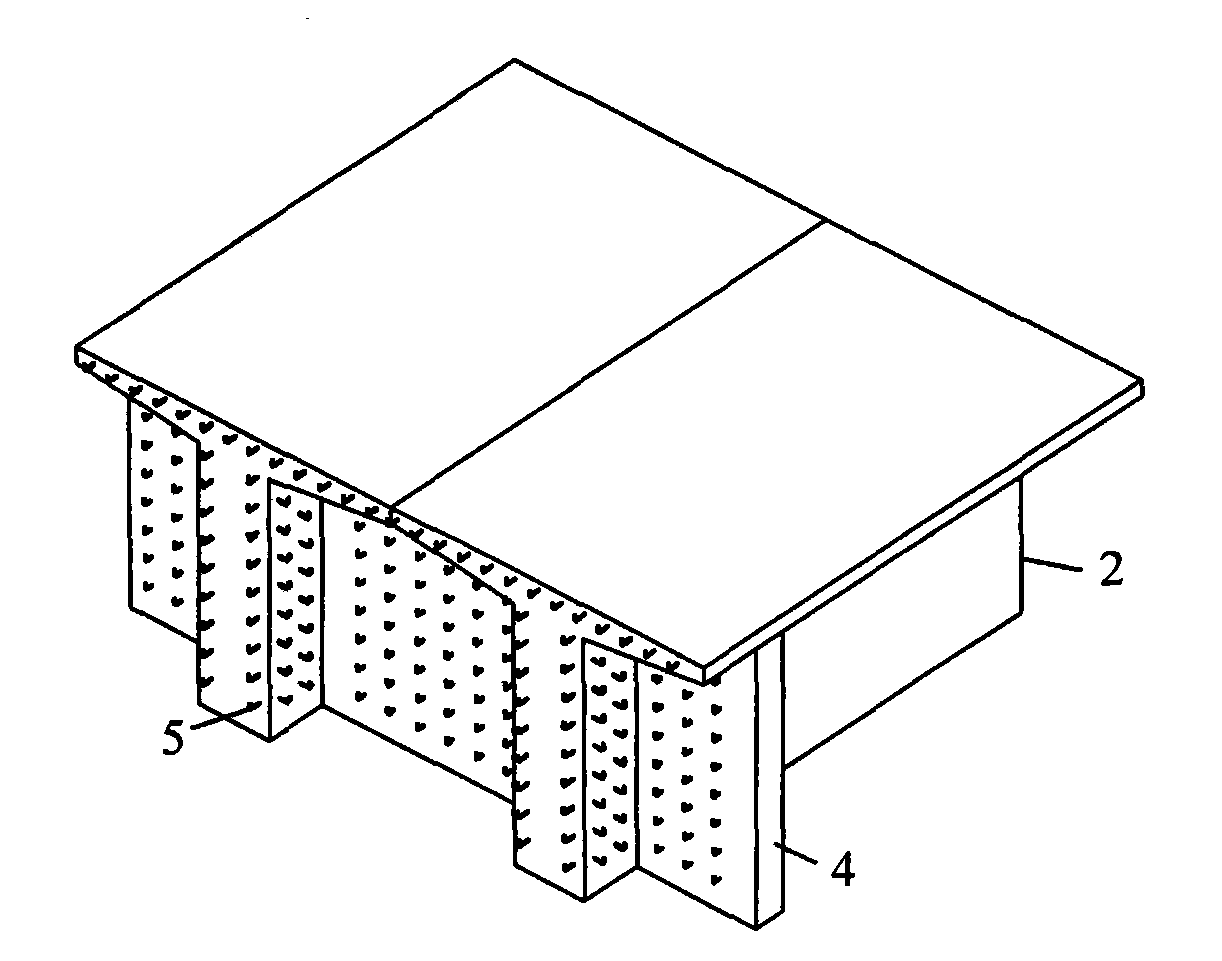

[0029] 1) Chiseling rough on the top surface of the original reinforced concrete T beam 2. The outer surface of the end of the original reinforced concrete T beam 2 and the outer surface of the original reinforced concrete T beam end partition 4 are chiseled, and L-shaped short steel bars 5 are planted in the chiseled place, such as image 3 shown;

[0030] 2) Make the steel structure part of the node area, such as Figure 4 shown. Firstly, steel girders are made. The height of the steel girder is the same as the height of the web plate of the original reinforced concrete T-beam 2. The transverse spacing between two adjacent webs of the steel beam 1 is the same as that of the original reinforced co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com