Crank case ventilation electronic control method and system

A technology of crankcase ventilation and electronic control, which is applied in crankcase ventilation, machines/engines, mechanical equipment, etc. It can solve problems such as high idle speed, difficult adjustment, and failure to reach crankcase pressure, etc., and achieve the effect of preventing engine oil from deteriorating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

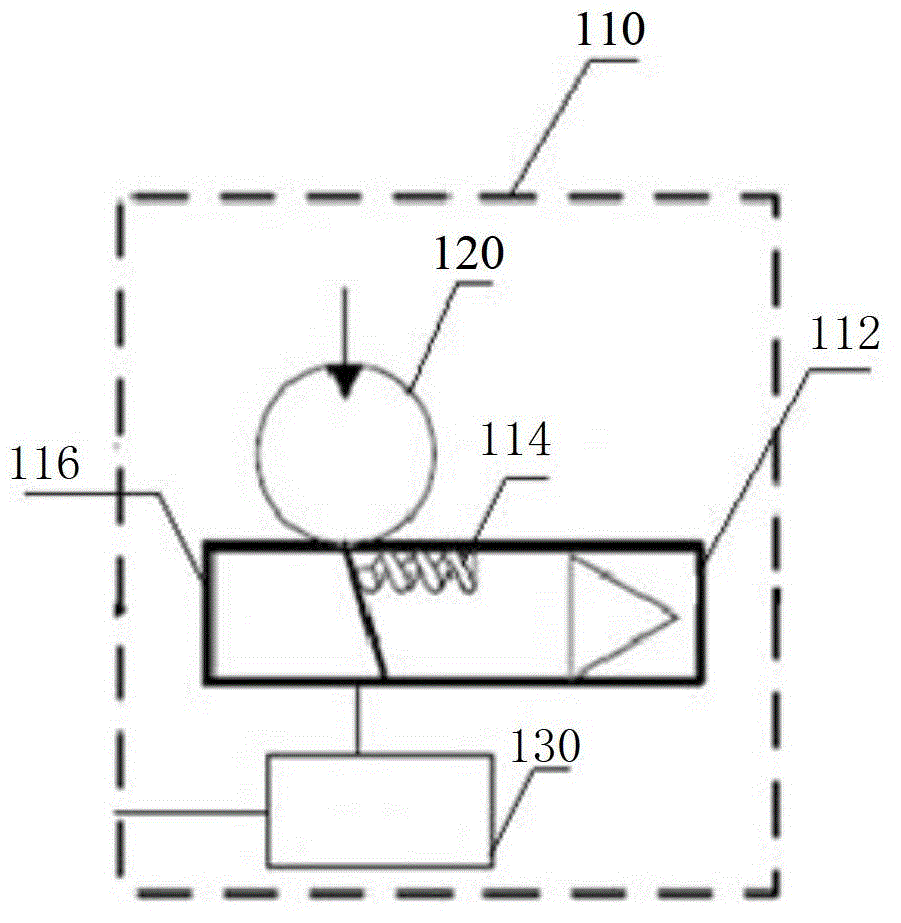

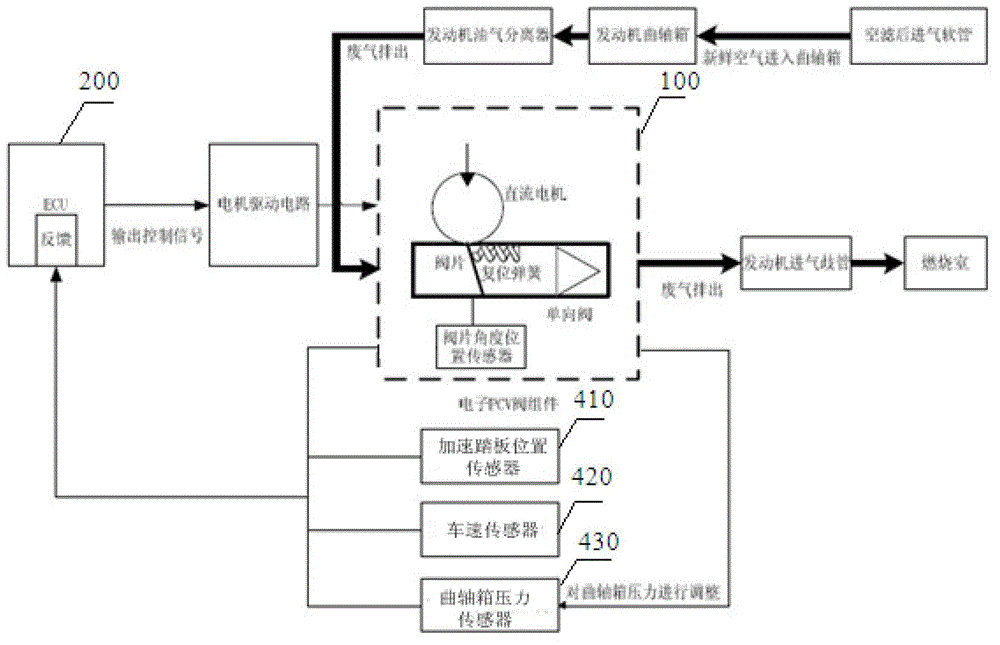

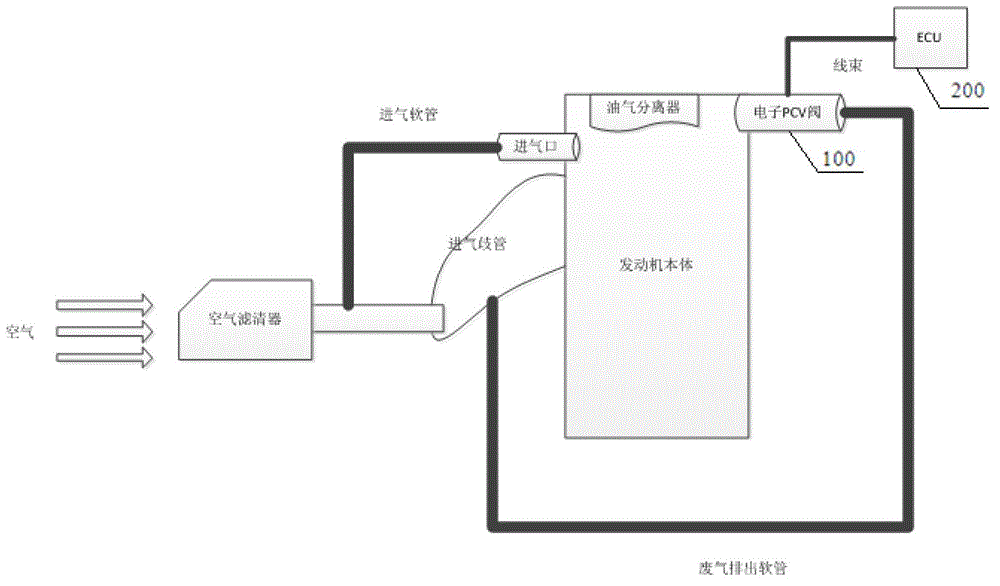

[0025] Such as figure 1 As shown, the present invention discloses an electronic PCV valve assembly 100, including a PCV valve 110, a DC motor 120 and a valve plate angular position sensor 130, the PCV valve 110 includes a valve 112 located on the air outlet of the valve body, and a valve located in the valve body The valve plate 114 and the return spring 116, the DC motor 120 and the return spring 116 are respectively connected with the valve plate 114, and the two cooperate to control the rotation of the valve plate 114 at a corresponding angle. The valve plate angle position sensor 130 is located on the valve plate 114 to monitor the valve plate 114 Sheet 114 deflects the angle.

[0026] The motor 120 will generate a corresponding torque under external control and apply it to the rotating shaft of the valve plate. When the torque generated by the motor 120 is equal to the tension value provided by the return spring 116, the valve plate 114 of the PCV valve 110 will be in a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com