Method for rapid determination of sodium formaldehyde sulfoxylate in food additive

A technology for rapid determination of food additives, applied to measuring devices, instruments, scientific instruments, etc., can solve problems such as poor parallelism, large matrix interference, and low sensitivity, and achieve high accuracy, small matrix interference, and high sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Sample pretreatment: Weigh 1.0g sample into a 150mL Erlenmeyer flask, add 30ml of an aqueous solution containing 10mmol / LKOH, shake at 150rpm for 40min, dilute to 50mL with 10mmol / LKOH aqueous solution, centrifuge at 7800r / min for 10min, Take 10mL of supernatant to pass through the C18 pretreatment cartridge, discard the first 5mL, keep the remaining 5mL sample for injection and detection.

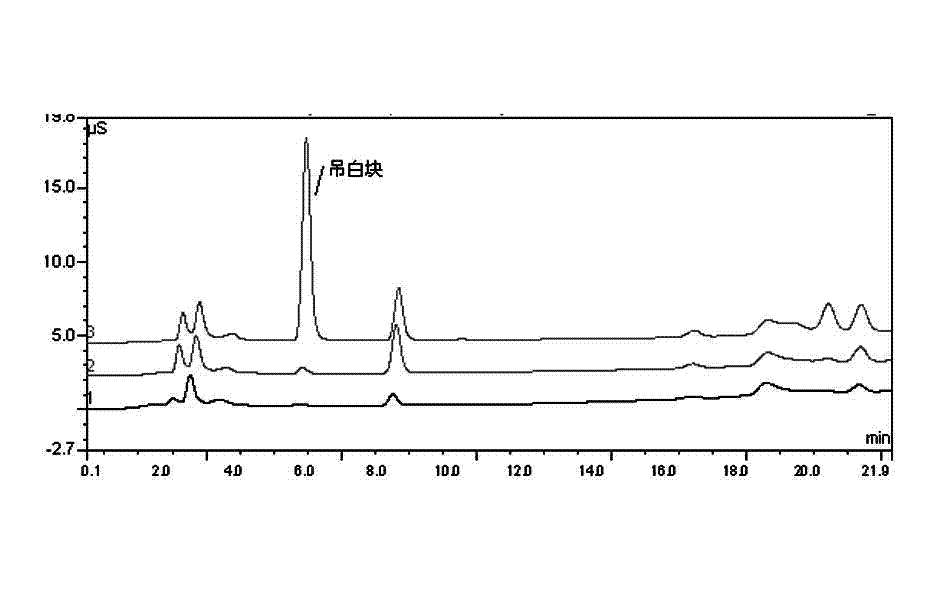

[0016] Chromatographic separation and detection: the chromatographic column is IonPac AS11 chromatographic column 4mm×250mm (with AS11-HG guard column 4mm×50mm), the mobile phase is KOH aqueous solution, and the gradient elution mobile phase is set to: contain OH at the beginning - The concentration is 5mmol / L, containing OH after 16min - The concentration is 25mmol / L, containing OH after 25min - The concentration is 5mmol / L, and the flow rate is stopped after 30 minutes; the elution flow rate: 1.2mL / min; the elution temperature: 30°C; the injection volume: 25uL; Electrode: platin...

Embodiment 2

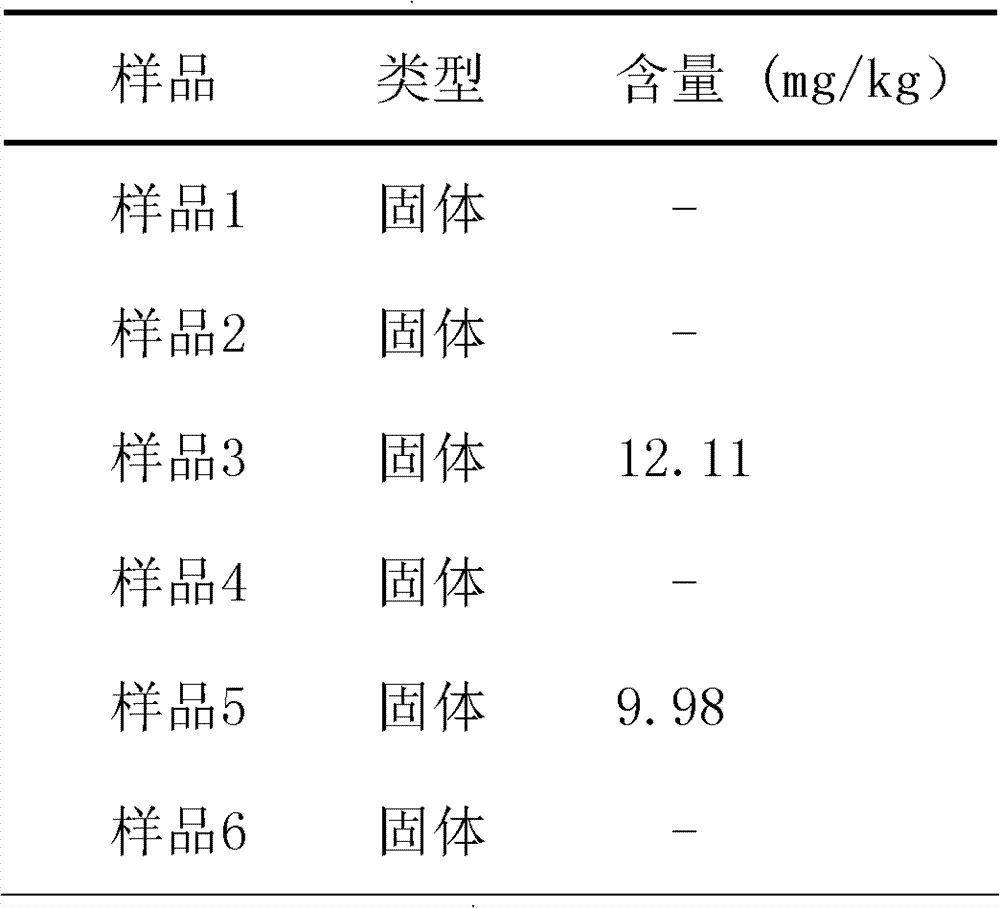

[0019] The established method was applied to the determination of Diaobaikuai in 54 solid food additives.

[0020] Sample pretreatment: Weigh 0.5g sample into a 150mL Erlenmeyer flask, add 35ml of an aqueous solution containing 20mmol / L NaOH, shake for 40min at 150rpm with an oscillator, dilute to 50mL with an aqueous solution of 20mmol / LNaOH, centrifuge at 7800r / min for 10min, Take 10mL of supernatant to pass through the C18 pretreatment cartridge, discard the first 5mL, keep the remaining 5mL sample for injection and detection.

[0021] Chromatographic separation and detection: the chromatographic column is IonPac AS11 chromatographic column 4mm×250mm (with AS11-HG guard column 4mm×50mm), the mobile phase is NaOH aqueous solution, and the gradient elution mobile phase is set to: contain OH at the beginning - The concentration is 5mmol / L, containing OH after 16min - The concentration is 25mmol / L, containing OH after 25min - The concentration is 5mmol / L, and the flow rate is...

Embodiment 3

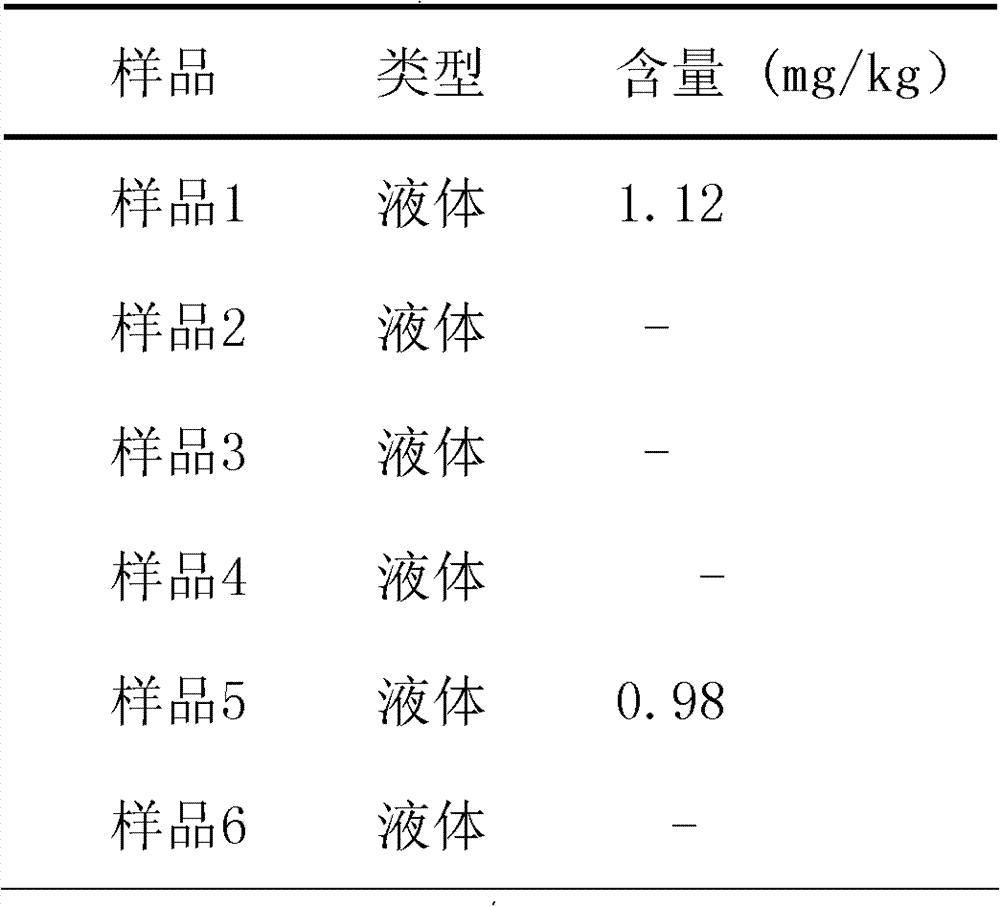

[0026] The established method was applied to the determination of Diaobaiku in 110 liquid food additives.

[0027] Sample pretreatment: Weigh 2.0g of sample into a 150mL Erlenmeyer flask, add 30ml of aqueous solution containing 10mmol / L NaOH, shake for 40min at 150rpm with an oscillator, dilute to 50mL with aqueous solution of 10mmol / LNaOH, centrifuge at 7800r / min for 10min, Take 10mL of supernatant to pass through the C18 pretreatment column, discard the first 5mL, keep the remaining 5mL sample for injection and detection.

[0028] Chromatographic separation and detection: the chromatographic column is IonPac AS11 chromatographic column 4mm×250mm (with AS11-HG guard column 4mm×50mm), the mobile phase is KOH aqueous solution, and the gradient elution mobile phase is set to: contain OH at the beginning - The concentration is 5mmol / L, containing OH after 16min - The concentration is 25mmol / L, containing OH after 25min - The concentration is 5mmol / L, and the flow rate is stoppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com