Cathode material for non-aqueous secondary battery and preparation method thereof as well as non-aqueous secondary battery cathode and non-aqueous secondary battery

A technology for non-aqueous secondary batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor cycle performance of high-capacity alloy negative electrode materials, and achieve poor cycle performance, good cycle characteristics, and high reversibility. The effect of specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

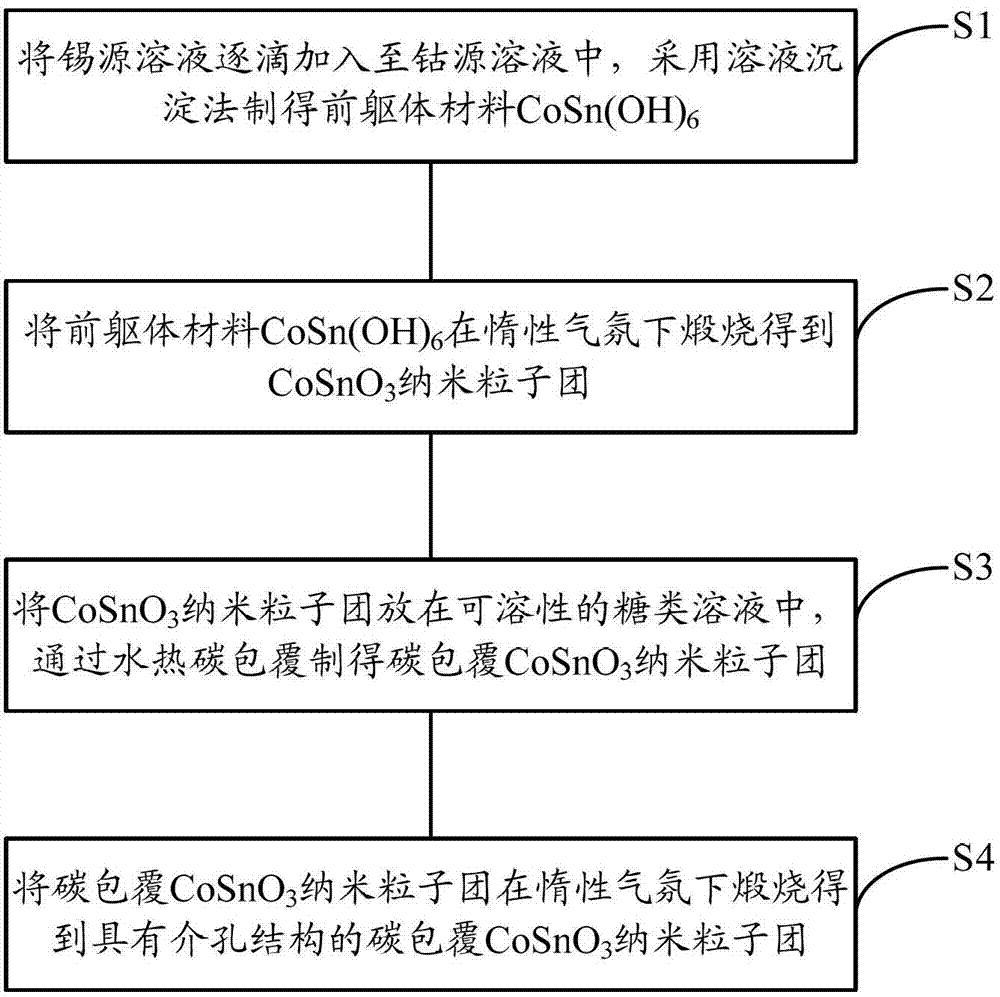

[0036] ginseng figure 1 As shown, the present invention also discloses a preparation method of a negative electrode material for a non-aqueous secondary battery, comprising:

[0037] S1. Add the tin source solution dropwise to the cobalt source solution, and use the solution precipitation method to prepare the precursor material CoSn(OH) 6 ;

[0038] S2, the precursor material CoSn (OH) 6 Calcined under an inert atmosphere to obtain CoSnO 3 nanoparticle clusters;

[0039] S3, the CoSnO 3 Carbon-coated CoSnO was prepared by hydrothermal carbon coating of nanoparticle clusters in a soluble sugar solution 3 nanoparticle clusters;

[0040] S4, the carbon coated CoSnO 3 Carbon-coated CoSnO with mesoporous structure obtained by calcination of nanoparticle clusters under inert atmosphere 3 nanoparticle clusters.

[0041] Preferably, the tin source solution in step S1 of the present invention is an aqueous solution of sodium stannate, the cobalt source solution is an aqueous ...

Embodiment 1

[0057] S1. Add 0.1 mol / L sodium stannate aqueous solution dropwise to 0.1 mol / L cobalt sulfate aqueous solution under vigorous stirring. After the reaction was completed, the stirring was continued for 30 min. Centrifuge the obtained precipitate, wash it with deionized water several times, and then dry the obtained precipitate at 80-110°C for 10 hours to obtain the precursor material CoSn(OH) 6 ;

[0058] S2, the above precursor material CoSn (OH) 6 Sintering at a constant temperature of 300-600°C for 2-6h under an inert atmosphere to obtain CoSnO 3 nanoparticle clusters;

[0059] S3, weigh a certain amount of CoSnO 3 Put in the hydrothermal liner of polytetrafluoroethylene, add a certain amount of 0.25mol / L glucose solution, stir for 0.5-2h and ultrasonic treatment for 10-60min, then transfer to a stainless steel hydrothermal tank, keep the temperature at 120-200℃ for 2- 24h. After natural cooling, the obtained sample was filtered, washed several times with deionized wa...

Embodiment 2

[0062] S1. Add 0.1 mol / L sodium stannate aqueous solution dropwise to 0.1 mol / L cobalt sulfate aqueous solution under vigorous stirring. After the reaction was completed, the stirring was continued for 30 min. Centrifuge the obtained precipitate, wash it with deionized water several times, and then dry the obtained precipitate at 80-110°C for 10 hours to obtain the precursor material CoSn(OH) 6 ;

[0063] S2, the above precursor material CoSn (OH) 6 Sintering at a constant temperature of 300-600°C for 2-6h under an inert atmosphere to obtain CoSnO 3 nanoparticle clusters;

[0064] S3, weigh a certain amount of CoSnO 3 Put in the hydrothermal lining of polytetrafluoroethylene, add a certain amount of 0.35mol / L glucose solution, stir for 0.5-2h and ultrasonic treatment for 10-60min, then transfer to a stainless steel hydrothermal tank, keep the temperature at 120-200℃ for 2- 24h. After natural cooling, the obtained sample was filtered, washed several times with deionized w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com